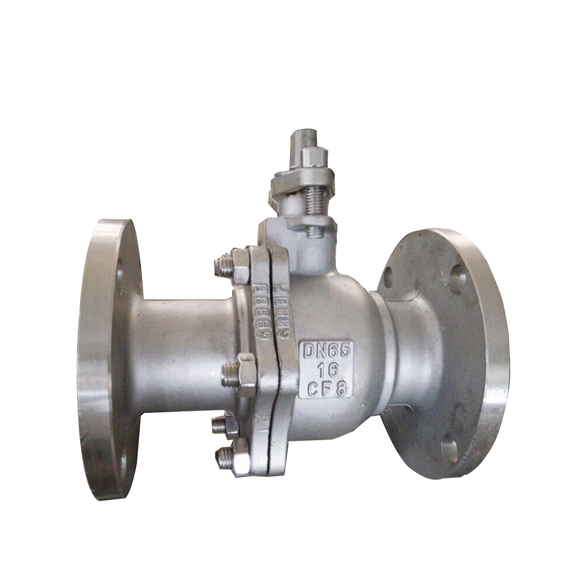

Characteristics and Application of Electric Ball Valve

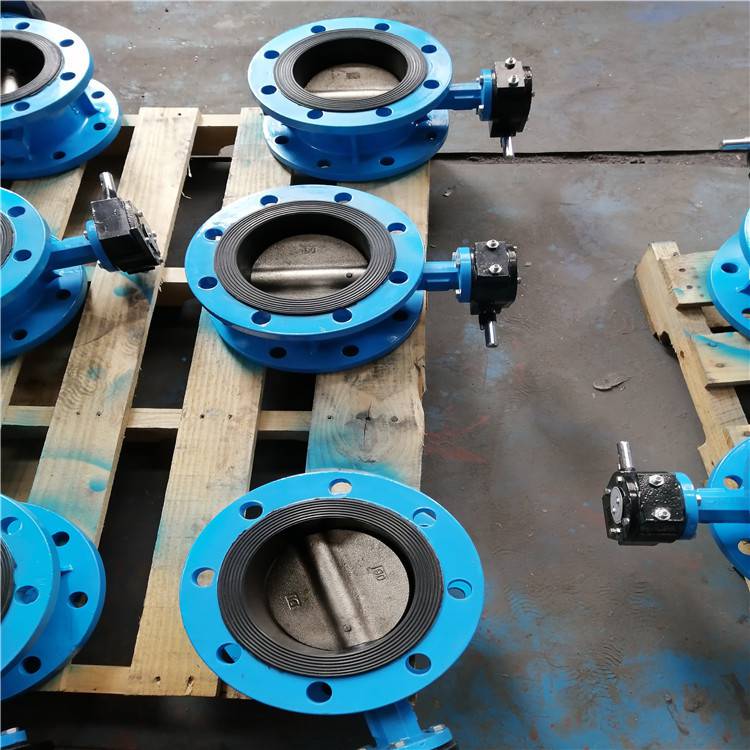

Ⅰ. Application of electric ball valve The electric ball valve is a rotary ball valve with a 90° rotation. It has excellent sealing performance, large flow capacity, small flow resistance coefficient, simple structure, convenient maintenance, and long service life. The valve body channel and the connecting pipe have the same diameter and form the same…