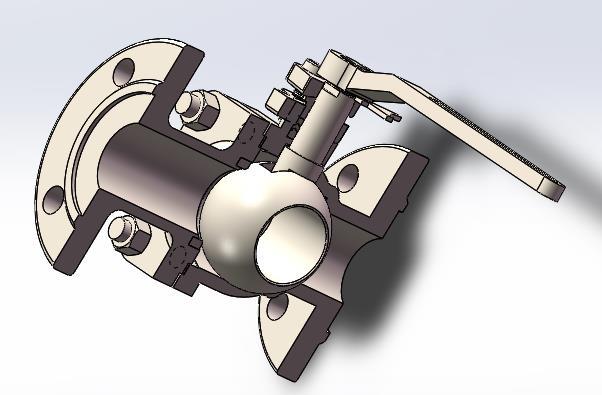

How to Convert a Manual Ball Valve into a Pneumatic Ball Valve?

Both manual ball valves and pneumatic ball valves are common types of valves, and they are widely used in industrial production. However, sometimes we need to convert a manual ball valve into a pneumatic ball valve to meet different working condition requirements. Now let’s take a detailed look at how to convert a manual ball valve into a pneumatic ball valve.

First of all, we need to understand what a pneumatic ball valve is. A pneumatic ball valve is a type of ball valve that uses compressed air or gas as the power source. It has the advantages of being fast, reliable, and safe, and is especially suitable for occasions where frequent opening and closing are required.

Next, let’s see how to convert a manual ball valve into a pneumatic ball valve.

The specific steps are as follows:

1.Replace the Valve Core:

The valve core of a manual ball valve is usually made of metal materials, while the valve core of a pneumatic ball valve is made of materials such as polytetrafluoroethylene (PTFE). Therefore, we need to replace the valve core of the manual ball valve with that of a pneumatic ball valve. This requires disassembling the original manual ball valve and reinstalling the valve core of the new pneumatic ball valve.

2.Replace the Sealing Ring:

The sealing rings of pneumatic ball valves and manual ball valves are also different. The sealing ring of a pneumatic ball valve is usually made of materials such as polytetrafluoroethylene (PTFE), while the sealing ring of a manual ball valve is made of materials such as rubber. Therefore, we need to replace the sealing ring of the manual ball valve with that of a pneumatic ball valve. This also requires disassembling the original manual ball valve and reinstalling the sealing ring of the new pneumatic ball valve.

3.Replace the Drive Device:

A pneumatic ball valve needs a drive device to work properly. A manual ball valve usually does not have a drive device, while a pneumatic ball valve requires a drive device such as a pneumatic motor or a cylinder. Therefore, we need to remove the original manual ball valve and install a new drive device such as a pneumatic motor or a cylinder.

4.Connect the Pipeline:

Finally, we need to connect the new pneumatic ball valve to the corresponding pipeline. This includes connecting the air source, connecting the actuator, etc. It should be noted that when connecting, make sure that all components are firmly connected to avoid affecting the subsequent use effect.

It should be noted that during the process of converting a manual valve into a pneumatic valve, safety issues need to be paid attention to. Especially when replacing the valve body and installing pneumatic components, relevant safety regulations need to be followed to avoid accidents. At the same time, the entire system also needs to be debugged and tested to ensure its normal operation.