Introduction to the Usage, Main Materials, and Structural Features of Wafer Check Valves

A check valve refers to a valve that automatically opens and closes,the valve disc relying on the flow of the medium itself, and is used to prevent the backflow of the medium. It is also known as a non-return valve, one-way valve, backflow valve, and backpressure valve. A check valve belongs to a type of automatic valve, and its main functions are to prevent the backflow of the medium, prevent the reverse rotation of the pump and the driving motor, and prevent the release of the medium in the container. The check valve can also be used on the pipeline that supplies the auxiliary system where the pressure may rise above the system pressure.

I. Usage of Wafer Check Valves:

The check valve is installed in the pipeline system, and its main function is to prevent the backflow of the medium. A check valve is an automatic valve that opens and closes relying on the pressure of the medium. Wafer check valves are suitable for various pipelines with a nominal pressure of PN1.0MPa to 42.0MPa, Class150 to 25000; a nominal diameter of DN15 to 1200mm, NPS1/2 to 48; and a working temperature of -196°C to 540°C, and are used to prevent the backflow of the medium.

By selecting different materials, they can be suitable for a variety of media such as water, steam, oil products, nitric acid, acetic acid, strongly oxidizing media, and uric acid.

II. Main Materials of Wafer Check Valves:

They include metal materials such as carbon steel, low-temperature steel, duplex steel (F51/F55), titanium alloy, aluminum bronze, Inconel (INCONEL), SS304, SS304L, SS316, SS316L, chromium-molybdenum steel, Monel (400/500), 20# alloy, and Hastelloy.

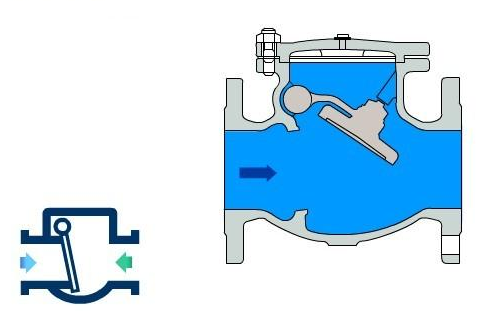

III. Structural Features of Wafer Check Valves:

- Short structural length, with its structural length being only 1/4 to 1/8 of that of the traditional flanged check valve.

- Small in size and light in weight, with its weight being only 1/4 to 1/20 of that of the traditional flanged check valve.

- The valve disc closes quickly, and the water hammer pressure is small.

- It can be used in both horizontal and vertical pipelines, and the installation is convenient.

- The flow channel is unobstructed, and the fluid resistance is small.

- Sensitive in action and good in sealing performance.

- Short stroke of the valve disc and small closing impact force.

- The overall structure is simple and compact, and the appearance is beautiful.

- Long service life and reliable performance.

IV. Common Faults of Check Valves:

1.The valve disc is broken.

When the pressures of the medium before and after the check valve are in a state close to balance and “sawing” each other, the valve disc often beats against the valve seat. The valve discs made of some brittle materials (such as cast iron, brass, etc.) will be broken. The preventive measure is to use a check valve with a valve disc made of tough materials.

2.The medium flows backward.

The sealing surface is damaged; impurities are caught in. By repairing the sealing surface and cleaning the impurities, the backflow can be prevented.