What is the Best Valve for Slurry Medium?

In industries such as petroleum, natural gas, chemical engineering, and sewage treatment, slurry is a common fluid medium, which is characterized by high viscosity and large particles. In order to ensure the normal transportation and treatment of slurry, it is necessary to select appropriate valves. This article will introduce several common slurry valves and analyze their advantages and disadvantages to help readers choose the most suitable valve.

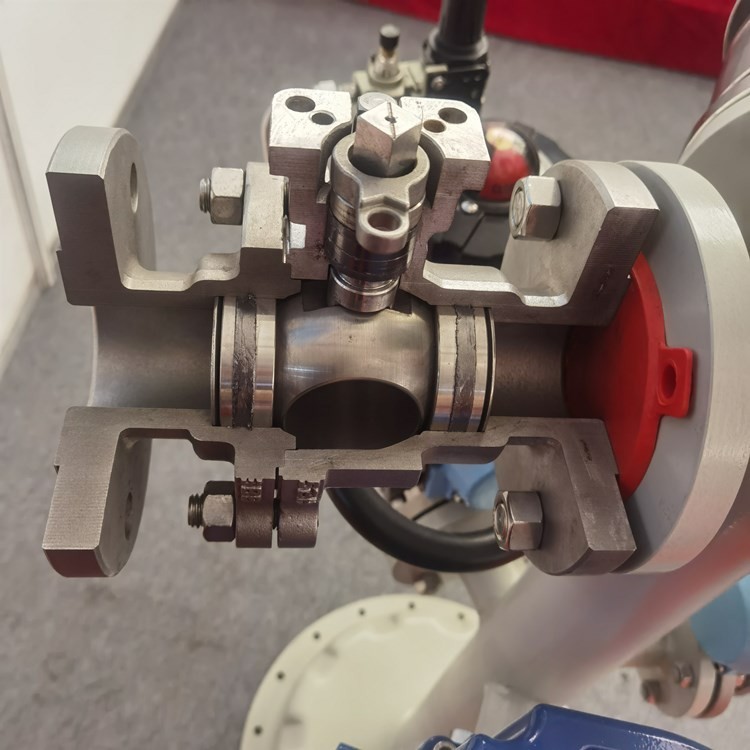

I. V-type Ball Valve

The V-type ball valve is a commonly used slurry valve, which has the following advantages:

- Good Sealing Performance: The V-type ball valve adopts a sealing method that combines an elastic sealing ring and a metal sealing surface, which can effectively prevent slurry leakage.

- Good Regulation Performance: The valve core of the V-type ball valve can rotate between 0° and 90°, enabling precise regulation of the slurry flow.

- Wear Resistance: The valve core and valve seat of the V-type ball valve are made of materials with high hardness, which can effectively resist the wear of the slurry.

However, the V-type ball valve also has some disadvantages:

- High Price: The manufacturing process of the V-type ball valve is relatively complex, so the price is relatively high.

- Not Suitable for High Temperature and High Pressure Environments: Components such as the sealing ring and valve core of the V-type ball valve are easily affected by high temperature and high pressure, thus affecting the service life of the valve.

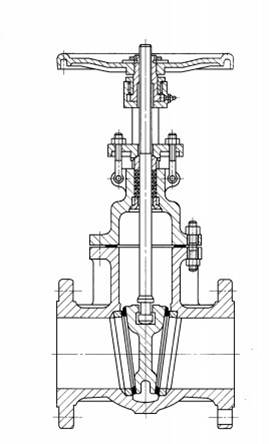

II. Gate Valve (Knife Gate Valve)

The knife gate valve is another commonly used slurry valve, which has the following advantages:

- Simple Structure: The structure of the knife gate valve is relatively simple, so the price is relatively low.

- Wear Resistance: The valve core and valve seat of knife gate valve are made of materials with high hardness, which can effectively resist the wear of the slurry.

- Suitable for High Temperature and High Pressure Environments: Components such as the sealing ring and valve core of knife gate valve can be made of materials resistant to high temperature and high pressure, so it is suitable for high temperature and high pressure environments.

However, the knife gate valve also has some disadvantages:

- Poor Sealing Performance: The sealing method of knife gate valve is linear sealing, so the sealing performance is relatively poor, and leakage is likely to occur.

- Poor Regulation Performance: The valve core of knife gate valve can only operate in the fully open and fully closed states, so the regulation performance is poor.

III. Other Slurry Valves

In addition to the V-type ball valve and the gate valve(knife gate valve), there are also some other types of slurry valves, such as butterfly valves, globe valves, etc. These valves also have their own advantages and disadvantages, and need to be selected according to specific application scenarios.

In summary, the V-type ball valve and the gate valve(knife gate valve) are two common slurry valves, each with its own advantages and disadvantages. When selecting a slurry valve, it is necessary to comprehensively consider according to specific application scenarios and requirements. If good sealing performance and regulation performance are required, a V-type ball valve can be selected; if a simple structure, low price, and wear resistance are required, a gate valve can be selected. In addition, it is also necessary to pay attention to parameters such as the valve material, pressure rating, and temperature range to ensure the safe and reliable operation of the valve.