Advantages, Disadvantages and Installation of Butterfly Valves

Overview of Advantages

As a fluid control device, the butterfly valve has numerous advantages due to its unique structure and design. Its main advantages include:

- High Flexibility: The valve plate design of the butterfly valve makes fluid control more flexible, enabling it to respond quickly and achieve precise flow regulation.

- Strong Durability: The butterfly valve, made of high-quality materials and through precise processing, ensures excellent durability and is suitable for various harsh working environments.

- Easy Maintenance: With its compact structure and easy disassembly, daily maintenance and upkeep become simple and easy, reducing maintenance costs.

- Energy Saving and Environmental Protection: The butterfly valve can achieve efficient energy utilization during the fluid control process, reducing energy waste and meeting the requirements of energy saving and environmental protection.

- In conclusion, with its outstanding flexibility and durability, the butterfly valve plays an increasingly important role in the field of fluid control.

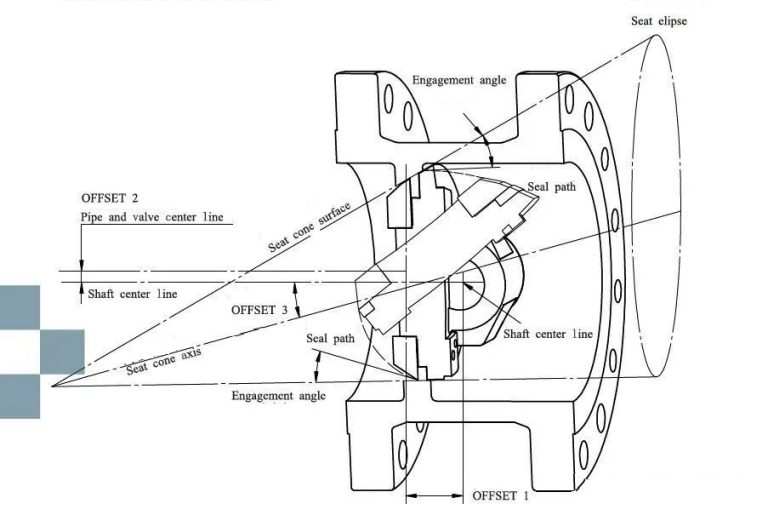

- Excellent Fluid Control Performance: When the butterfly valve is in the fully open state, the thickness of its butterfly plate is only a small resistance to the fluid passing through the valve body, thus keeping the pressure drop through the valve to a minimum. In addition, due to the compact structure of the butterfly valve, its length and overall height are relatively small, enabling rapid opening and closing actions, and thus demonstrating excellent flow control characteristics.

- An Ideal Choice in the Field of Large Diameter Regulation: When the opening angle of the butterfly valve is between approximately 15° and 70°, its flow control function is particularly sensitive. Precisely because of this, the butterfly valve is quite widely used in the field of large diameter regulation.

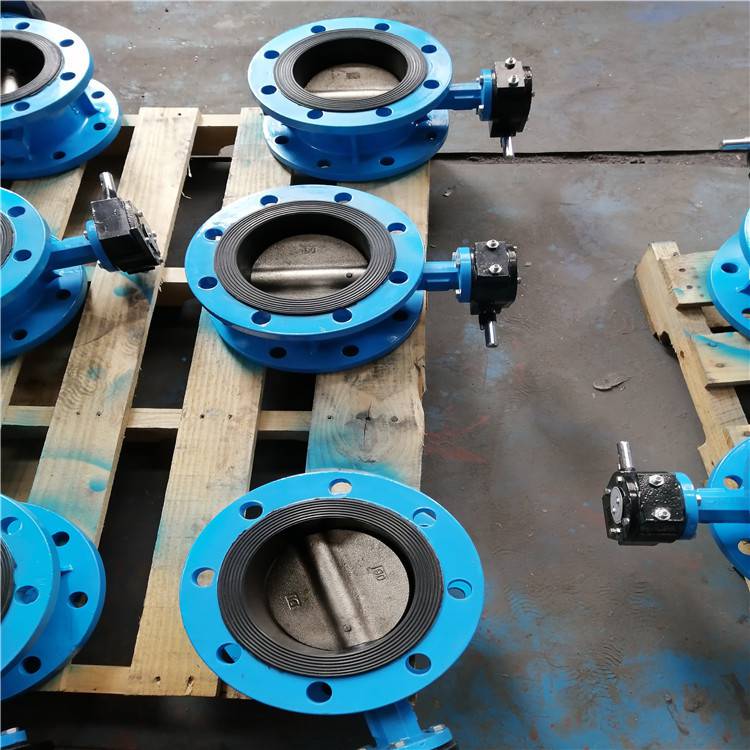

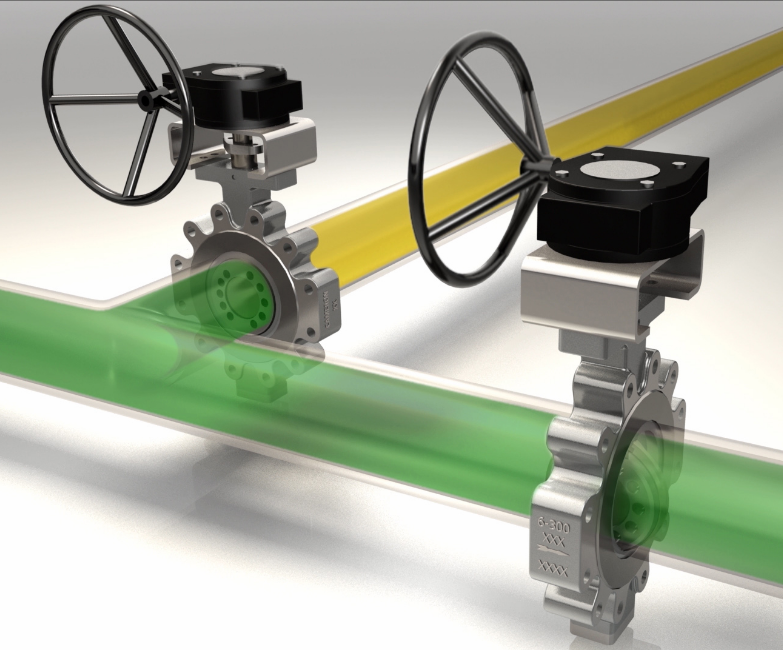

- Compact Structure and Obvious Cost Advantage: The butterfly valve has secured its place in the pipeline system with its lightweight structure and compact body design. Its flow control mechanism uses a thin metal disc. Although it is small in size, it has excellent strength and can effectively regulate fluid flow. In addition, the butterfly valve uses less manufacturing materials. Compared with other valves of the same size, such as ball valves, its price is more affordable, providing an economical and practical solution for pipeline systems in narrow locations.

- Quick and Efficient Sealing: The unique design of the butterfly valve enables it to achieve rapid sealing when started, making it an ideal choice for high-precision flow control applications.

Low Pressure Drop and High Pressure Recovery: Although the valve disc is always immersed in the fluid, the design of the butterfly valve can maintain a low pressure drop. This low pressure drop characteristic is crucial for optimizing the pumping efficiency of the management system and reducing energy consumption. In addition, its unique design also ensures that the fluid can quickly recover to a high pressure state after passing through the valve. - Simple Maintenance Requirements: The internal structure of the butterfly valve is streamlined. Compared with other valves, it has no “trap” areas that can capture fluids or impurities. Therefore, the maintenance requirements are relatively low, reducing frequent maintenance and intervention. In addition, the installation process of the butterfly valve is also quite simple. It only needs to be clamped between adjacent pipeline flanges without complex welding steps.

Easy Operation: The butterfly valve has a quite compact structure and is light in weight. Therefore, it can be easily operated with only a low torque. Its thin metal butterfly plate can easily overcome the frictional resistance of the fluid and can be smoothly opened and closed with only a small amount of force. - Easy Automation: Since small actuators can provide sufficient torque for the butterfly valve, making its operation more convenient and thus reducing operating costs. This is mainly because small actuators have lower power consumption and do not significantly increase the overall cost of the valve.

Disadvantages and Challenges

Although small actuators have significant advantages in providing convenient operation for butterfly valves, they also have some drawbacks. One of them is that they may not be able to cope with extreme environmental conditions, such as high temperatures, low temperatures, or corrosive environments, which may limit their application range. In addition, although small actuators have advantages in terms of power consumption and cost, in some special cases, their performance may not meet specific application requirements. Therefore, when selecting an actuator, it is necessary to comprehensively consider according to the specific application scenarios and requirements.

Application Limitations of Butterfly Valves

- 1.The butterfly valve has certain limitations in throttling. It is mainly suitable for throttling operations in low-pressure environments, and its opening range is usually limited between 30 degrees and 80 degrees. For applications beyond this range, the butterfly valve may not be able to effectively perform the throttling task.

- 2.The butterfly valve is vulnerable to cavitation and blocked flow.

- When the butterfly valve is in the open state, it does not provide a completely closed port. At this time, the presence of the valve disc in the fluid flow path often aggravates the accumulation of impurities around the valve, thereby increasing the probability of cavitation.

- 3.Relatively Weak Corrosion Resistance

- Compared with gate valves and ball valves, the butterfly valve has relatively weak corrosion resistance. During the process of the fluid flowing through the butterfly valve, due to the scouring effect of the fluid, the material of the disc may gradually deteriorate, affecting its sealing performance. Especially when dealing with viscous fluids, the corrosion rate of the butterfly valve may increase further.

- 4.Difficult Pigging

- When the valve disc of the butterfly valve is in the fully open state, it may hinder the cleaning process of the entire system, resulting in ineffective pigging operations for the pipeline containing the butterfly valve.

Installation and Maintenance of Butterfly Valves

- The installation of the butterfly valve is crucial for its normal operation. During the installation process, it is necessary to ensure that the correct steps and specifications are followed to ensure that the butterfly valve can smoothly perform its functions. At the same time, regular maintenance is also essential. It can promptly detect and solve potential problems, thus extending the service life of the butterfly valve.

- 1.When installing the butterfly valve, ensure that the valve disc is in the closed state.

- 2.The opening position of the butterfly valve needs to be accurately set according to the rotation angle of the butterfly plate.

- 3.If the butterfly valve is equipped with a bypass valve, the bypass valve should be opened first for pre-treatment before opening the main valve.

- 4.During the installation process, be sure to follow the installation instructions provided by the manufacturer. Especially for butterfly valves with a large weight, ensure that a stable foundation is set up.