The Differences between the Center Line and the Eccentric Butterfly Valves.

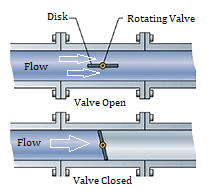

Center Line Butterfly Valve

The center line butterfly valve is also known as the center line soft sealing butterfly valve. Its most prominent structural feature is that the axis of the valve stem, the center of the butterfly disc, and the center of the valve body passage are in the same position. The center line butterfly valve can only be of soft sealing type. Commonly used materials for the valve seat include ethylene propylene diene monomer (EPDM) rubber, nitrile rubber, and polytetrafluoroethylene (PTFE). These valves are applied in working conditions with normal temperature and low pressure. The center line butterfly valve has good sealing performance but is not resistant to high temperature and high pressure.

Eccentric Butterfly Valve

The eccentric butterfly valve is a general term, mainly including the single eccentric butterfly valve, the double eccentric butterfly valve, and the triple eccentric butterfly valve. The performances of these three types of eccentric butterfly valves are also different from each other.

1.Single Eccentric Butterfly Valve

The structural feature of the single eccentric butterfly valve is that the axis of the valve stem deviates from the center of the butterfly disc, so that the upper and lower ends of the butterfly disc no longer serve as the axis of rotation, which disperses and reduces the excessive extrusion between the upper and lower ends of the butterfly disc and the valve seat. However, due to the single eccentric structure, the scraping phenomenon between the butterfly disc and the valve seat does not disappear during the entire opening and closing process of the valve. Its application range is similar to that of the concentric butterfly valve, and the sealing performance of the single eccentric butterfly valve is even inferior to that of the center line butterfly valve. Therefore, this type of butterfly valve is rarely used.

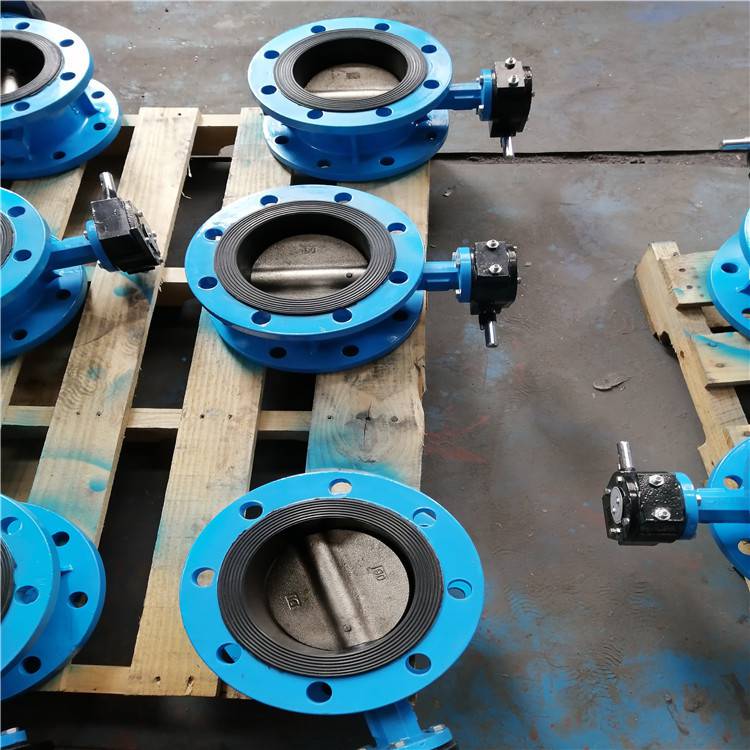

2.Double Eccentric Butterfly Valve

The double eccentric butterfly valve, which is a further improved version of the single eccentric butterfly valve, is a type of eccentric butterfly valve that is currently widely used. Its structural feature is that the axis of the valve stem deviates from both the center of the butterfly disc and the center of the valve body. Its disadvantage is also that it is not resistant to high temperature and high pressure, and there is a certain amount of leakage.

3.Triple Eccentric Butterfly Valve

The main structural feature of the triple eccentric butterfly valve is that while the axis position of the valve stem is eccentric in the double eccentric structure, the conical axis of the sealing surface of the butterfly disc is skewed relative to the cylindrical axis of the valve body. After the third eccentricity, the sealing section of the butterfly disc is no longer a true circle but an ellipse, and the shape of its sealing surface is also asymmetrical as a result. One side is inclined to the center line of the valve body, and the other side is parallel to the center line of the valve body. The triple eccentric butterfly valve has solved the problem of large leakage of the metal valve seat, and since the contact surface pressure is proportional to the medium pressure, the resistance to high pressure and high temperature has also been successfully addressed.