Methods for Troubleshooting of Soft Sealed Gate Valves

Ⅰ.Leakage at the Packing of Soft Sealed Gate Valves

1.The packing gland is too loose

Evenly tighten the nuts used to compress the packing gland.

2.Insufficient number of packing turns

Increase the amount of packing.

3.Packing failure

If the packing fails due to long term use or improper storage, new packing needs to be replaced. When replacing, note that the joints of each turn of packing should be staggered by 120°.

Ⅱ.Leakage between the Gate Plate and the Seat Sealing Surface of Soft Sealed Gate Valves

1.Impurities are trapped between the sealing surfaces

Remove the impurities between the sealing surfaces by flushing.

2.Damage to the sealing surface

If there is damage to the sealing surface, it needs to be reground. If necessary, surfacing welding repair and subsequent processing can be carried out. The reground sealing surface should be flat, and the surface roughness should not be lower than 0.4.

Ⅲ.Leakage at the Connection between the Valve Body and the Valve Cover of Soft Sealed Gate Valves

1.Nut fastening issues

If the nuts are not tightened or the tightening degree is inconsistent, readjust them.

2.Damage to the flange sealing surface

If there is damage to the flange sealing surface (such as straight grooves or scratches), it should be repaired.

3.Gasket damage

Replace with a new gasket.

Ⅳ.Inflexible transmission of the valve stem of soft sealed gate valves

1.The packing is compressed too tightly

Appropriately loosen the nuts on the packing gland.

2.The packing gland is misaligned

If the misalignment of the packing gland causes the valve stem to jam, evenly turn the nuts on the packing gland to restore the gland to its normal position.

3.Damage to the threads of the valve stem and the valve stem nut

After disassembly, repair the damaged threads on the valve stem and the valve stem nut.

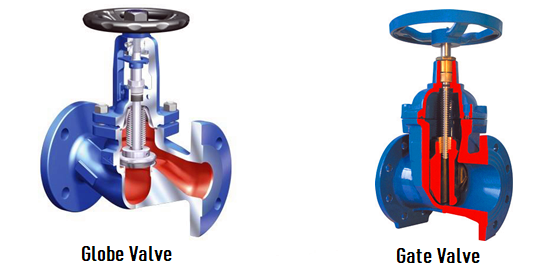

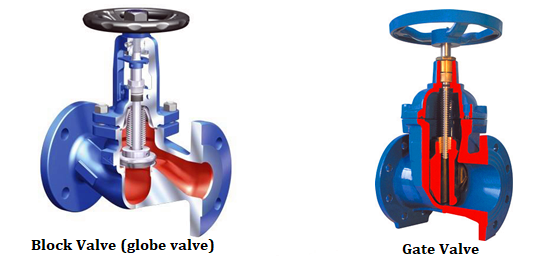

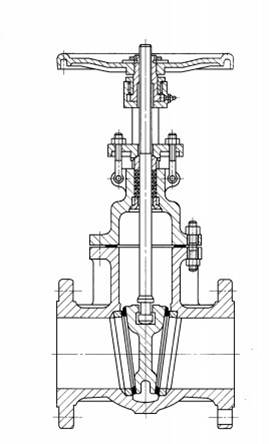

Soft sealed gate valves are widely used and belong to industrial valves. Their opening and closing part is the gate plate, and the movement direction of the gate plate is perpendicular to the fluid direction. Gate valves can only be fully opened or fully closed and cannot be used for flow regulation and throttling. The gate plate has two sealing surfaces. For common wedge shaped gate plate valves, the two sealing surfaces are wedgeshaped. The wedge angle varies with different valve parameters, generally 50°; when the medium temperature is not high, the wedge angle is 2°52′.