Introduction to Non Slam Check Valve

A non slam check valve is a check valve non slam type that can prevent the slam or water hammer when the valve closes. Because the no slam check valve is equipped with a special pressure reducing device. Before the valve closes, it can quickly reduce the liquid pressure inside the pipeline to below the environmental pressure, thereby effectively avoiding the slam phenomenon.

I. The structure of non slam check valve.

A non-slam check valve is mainly composed of the following parts:

- Valve body: the valve body is usually made of materials such as ductile iron and carbon steel, which have good corrosion resistance and durability.

- Valve disc: the valve disc can be spherical, conical, or annular, and it can prevent the backflow of fluid when the valve closes.

- Pressure reducing device: the pressure reducing device usually consists of a piston with a spring. Before the valve closes, it can quickly reduce the liquid pressure in the pipeline, thus achieving a non slam effect.

- Sealing part: the sealing parts are usually made of materials such as polyurethane and polytetrafluoroethylene, which can ensure the tightness of the valve and a long service life.

II. Non slam check valve types.

Sorted by structural forms.

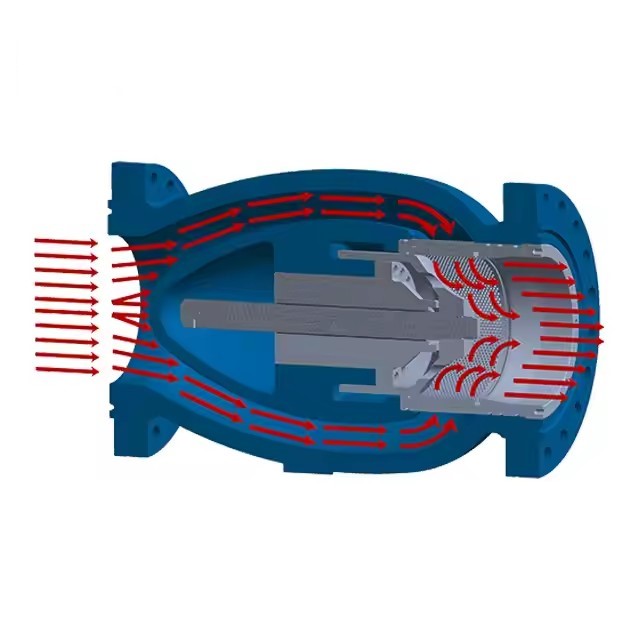

- Axial flow non slam check valve: it adopts a venturi-type internal structure design. When the fluid flows through the valve passage, it experiences a process of gradual contraction and expansion, minimizing the generation of eddy currents. It has the characteristics of fast closing, minimizing the destructive effect of water hammer in the fluid system, protecting rotating equipment from damage caused by fluid backflow, low mechanical vibration, and low noise, and can achieve a truly non slam operation.

- Micro-resistance slow closing butterfly non slam check valve: it is mainly composed of a valve body, two semi-circular valve discs, a return spring, an oil storage cylinder, a slow closing small cylinder group, a needle valve, etc. During the closing process, through the slowclosing system, the needle valve is used to adjust the oil flow in the oil pipe, so as to adjust the slow closing time. It can effectively limit the destructive water hammer and achieve non slam closing.

- Silent non slam check valve: the internal water flow passage adopts a streamlined design, and the valve disc has an annular structure, which greatly reduces the weight of the valve disc. The water flow can pass through both the inner and outer sides of the valve disc. The rear end deflector makes the water flow almost free of turbulence. It has a bearing-less design, and only spring and reed assemblies are used to evenly support the annular valve disc in the circumferential direction, making the movement of the valve disc friction free. It can close quickly, eliminate the wear of internal parts and head loss, reduce energy consumption, and achieve silent and non slam operation.

Sorted by connection methods.

Wafer type non slam check valve: it is installed between two pipe flanges and is firmly connected to the pipe flanges by bolts. It has the characteristics of easy installation and small space occupation.

Flanged non slam check valve: it is connected to the pipeline through flanges, with high connection strength and good sealing performance. It is suitable for pipeline systems of various pressures and diameters.

Welded non slam check valve: the valve is connected to the pipeline by welding. The connection is firm and the sealing performance is good. It is suitable for harsh working conditions such as high temperature and high pressure, but the installation and disassembly are relatively difficult.

Sorted by materials.

- Non-slam check valves made of metal: check valves made of materials such as carbon steel, stainless steel, cast steel, and forged steel have the characteristics of high strength, good pressure resistance, and high temperature resistance. They are suitable for various industrial fields, such as petroleum and chemical, power, and metallurgy.

- Non-slam check valves made of non-metal materials: check valves made of materials such as plastics and ceramics have good corrosion resistance and wear resistance. They are suitable for some special requirement occasions, such as the transportation of corrosive chemical media and the transportation of pure water.

- Non-slam check valves made of composite materials: They are made of a combination of metal and non-metal materials, combining the strength of metal materials and the corrosion resistance of non-metal materials, which can meet the requirements of some complex working conditions.

III. The application of non slam check valves.

Non slam check valves are widely used in various industrial fields, especially in the fields of petrochemical, metallurgy, and power, where they have important application values. They can prevent the impact phenomenon when the liquid is flowing through the valve during closing, protecting the safety of equipment such as pipelines and valves. In addition, non slam check valves also have the advantages of energy saving and environmental protection, which can effectively reduce energy consumption and wastewater discharge.