What is a Jockey Pump Foot Valve?

Jockey Pump Foot Valv

In a fire protection system, a jockey pump foot valve plays a crucial yet often under-the-radar role. To understand its significance, we need to first look at the context of the jockey pump itself.

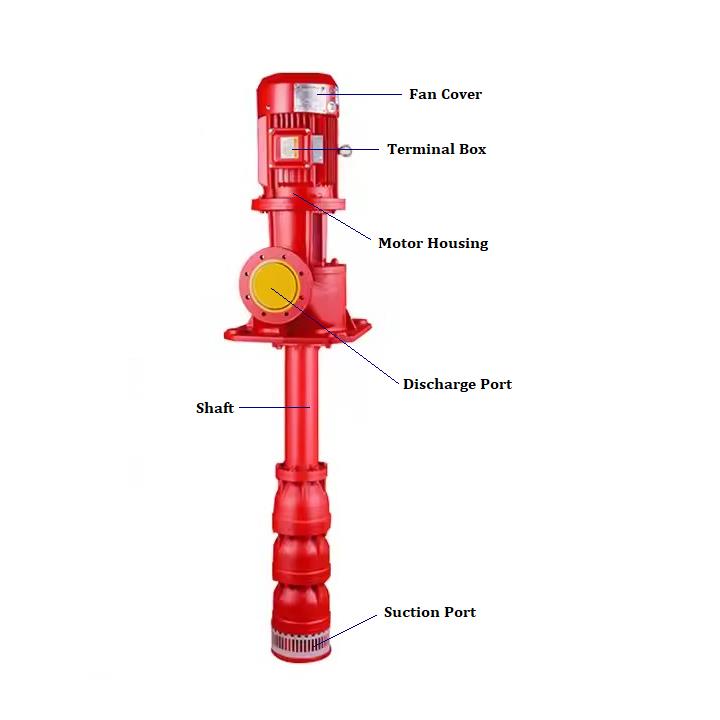

A jockey pump is an essential component within a fire protection system. Its primary function is to maintain the required pressure in the fire-suppression piping network during non-emergency periods. Fire protection systems need to be constantly primed and ready to deliver large volumes of water at the appropriate pressure in the event of a fire. The jockey pump ensures that any minor pressure drops due to small leaks or normal system fluctuations are quickly corrected, keeping the system in a state of constant readiness.

Introduction to the foot valve

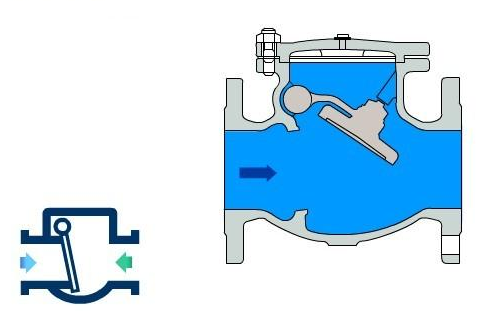

The foot valve associated with a jockey pump is a specialized type of check valve. It is typically installed at the intake or suction side of the jockey pump, usually at the lowest point of the suction line. The name “foot valve” comes from its position, as if it were at the “foot” of the pump’s intake.

Structure and cesign of a foot valve.

Valve Body: The body of a jockey pump foot valve is designed to be robust and resistant to corrosion, as it often comes into contact with water that may contain various impurities. It is commonly made of materials such as cast iron, stainless steel, or bronze. These materials ensure durability and long-term performance in a potentially harsh environment.

Flap or Disc Mechanism: Inside the valve body, there is a flap or disc that acts as the main control element. When the jockey pump is operating and creating a suction force, the flap is lifted, allowing water to flow freely from the water source (such as a water tank or a municipal water supply connection) into the pump. When the pump stops or when there is a reverse flow tendency in the suction line, the flap closes tightly under the pressure of the water, preventing the water from flowing back.

Strainer Attachment: Many jockey pump foot valves come with an integrated strainer. The strainer is located at the inlet of the foot valve and is designed to prevent debris, dirt, and other solid particles from entering the pump. This is crucial because any foreign objects in the pump can cause damage to the pump’s impeller and other moving parts, leading to reduced efficiency or even pump failure.

Function of the Jockey pump foot valve.

- Preventing Backflow: The most fundamental function of the foot valve is to prevent backflow in the suction line. When the jockey pump stops running, if there were no foot valve, the water in the suction line would flow back to the source due to gravity or pressure differentials in the system. This backflow could cause air to enter the suction line, which would then require the pump to be primed again before it could effectively operate. By closing immediately when the pump stops, the foot valve ensures that the suction line remains filled with water, allowing the jockey pump to start up smoothly and quickly when needed.

- Maintaining System Pressure: In a fire protection system, maintaining a consistent pressure is of utmost importance. The jockey pump foot valve contributes to this by working in tandem with the jockey pump. As the jockey pump adjusts the pressure in the system, the foot valve ensures that the water being pumped into the system stays in the system and that no pressure is lost due to backflow in the suction line. This helps in keeping the overall fire protection system pressure stable, ready to respond to any fire emergency.

- Protecting the Jockey Pump: The integrated strainer in the foot valve acts as a first – line defense for the jockey pump. By filtering out debris, it protects the pump’s internal components from damage. A clean – running pump is more efficient and has a longer lifespan. Additionally, by preventing backflow, the foot valve also protects the pump from potential damage that could occur if air – filled lines caused cavitation during the pump’s startup.

Installation and maintenance of the Jockey pump foot valve.

In conclusion, the jockey pump foot valve, despite its small size compared to some other components in a fire protection system, is a vital part that ensures the smooth operation, pressure maintenance, and protection of the jockey pump and the overall fire protection network. Its proper functioning is essential for the reliability of the fire protection system, which in turn is crucial for safeguarding lives and property.

- Installation: Proper installation of the jockey pump foot valve is crucial. It must be installed at the lowest point of the suction line to ensure that it can effectively prevent backflow. The valve should be installed in a horizontal or vertical position according to the manufacturer’s instructions. If installed vertically, care must be taken to ensure that the flap closes properly under gravity. The connection to the suction line should be air – tight to prevent any air leakage, which could affect the pump’s performance.

- Maintenance: Regular maintenance of the foot valve is essential for its continued proper functioning. This includes periodic inspection for signs of corrosion, wear, or damage to the valve body and the flap. The strainer should be cleaned regularly to remove any accumulated debris. If the foot valve shows signs of malfunction, such as failure to close properly or excessive leakage, it should be repaired or replaced immediately to ensure the integrity of the fire protection system.