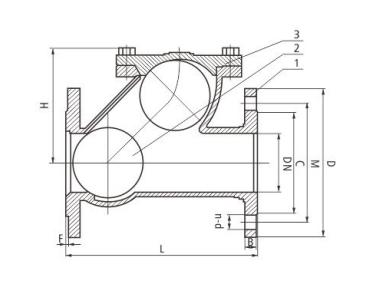

Axial Check Valve

The axial check valve is a specially designed valve. The opening and closing of the valve disc are operated by the pressure difference between the inlet and the outlet end of the valve. It can effectively prevent the backflow of the medium and ensure the safety of the pipeline. This design aims to solve the application problems of the lift check valve in vertical pipes.

Axial check valves feture small fluid resistance, light size, reliable sealing, and a simple structure. It is mainly composed of components such as the valve body, valve cover, valve disc, spring, and valve stem. The entire structure is compact and can be applied to prevent the backflow of various media.

Technical Specifications

- VALVE DESIGN

based on API 6D and customer requirements - TEMPERATURE RANGE

-150 to 662°F (-101 to 350°C) - SIZE

NPS 2 – 56 (DN 50-1400) - PRESSURE RATING

ASME 150 – ASME 2500 - FACE-TO-FACE

As per API 6D standard - END CONNECTIONS

RF, RTJ as per B16.5 &B16.47

BW, Butt Welded as per B16.25 - BODY DESIGN

Cast one piece / bolted two pieces for size >20 inch.

Forged bolted one-piece/ three-piece - SEAT DESIGN

Metal-seated with hard facing on disk and seat

The data is for reference only, please consult sales@wayvalve.com for details.

Main features of axial check valve.

- Axial flow

- Low pressure loss

- Tight shut-off

- Low cracking pressure

- Easy opening and stable operation

- Non-slam operation

- Maintenance free

- Reliable performance prediction

Applications of axial flow check valves.

Axial check valves are specifically designed for fast-reversing systems where backflow is a constant concern. It is categorized as a non-slam check valve as the valve closes without slamming meaning no excess pressure spikes are created. Most axial flow check valves are spring-loaded, with a single low-mass disc, which facilitates fast, dynamic response to a reduction in flow. Due to having a single disc and spring when the disc is opening, the force is balanced resulting in an even flow.

It is widely applied in fields such as petroleum, natural gas, and fire protection, and is especially suitable for the outlets of oil pipeline pumps and gas pipeline compressors, effectively preventing the backflow of the medium.

PEOPOLE ALSO ASK

What is the function of the axial valve?

An axial valve (also known as an axial flow valve) primarily controls fluid flow by allowing media (liquid or gas) to move parallel to the valve’s axis. Its design typically features a disc, piston, or other movable component that opens or closes along the axial direction. Key roles include:

Regulating Flow Rate: Adjusting the position of the internal component to control the volume of fluid passing through, suitable for applications requiring precise flow management.

Minimizing Pressure Drop: Offering a streamlined flow path, which reduces energy loss and pressure loss compared to some other valve types (e.g., globe valves).

Direction Control: In some designs, limiting flow to one direction (similar to a check valve) or allowing bidirectional flow, depending on the application (e.g., in pumps, pipelines, or hydraulic systems).

Isolation: Fully closing to shut off flow entirely, though this is less common than in gate or ball valves.

Axial valves are widely used in industries like water treatment, power generation, and HVAC systems for their efficiency in high-flow, low-pressure-drop scenarios.

What is an axial flow check valve?

An axial flow valve is an axial valve as well as a check valve. It consists of key components like the valve body, piston or disc, spring, and stem. Its design allows for a compact structure with low fluid resistance and reliable sealing. An axial check valve functions based on the pressure difference between the inlet and outlet. Its movable component (a piston or disc) opens when fluid flows forward under pressure and closes via spring force or backpressure to block reverse flow, allowing fluid to flow in one direction along the valve’s axis.

It’s widely used in industries such as petroleum and natural gas, especially at the outlets of pumps and compressors, to prevent medium backflow and ensure the safe operation of pipelines.

What is the difference between swing check valves and axial flow check valves?

swing check valves use a hinged disc that swings open with forward flow and closes by gravity/flow reversal to prevent backflow, ideal for low-to-medium flow rates and horizontal pipelines.

Axial flow check valves have a piston or disc that moves along the valve’s axis (inline), opening via flow pressure and closing via spring/pressure to block backflow. It suits high-flow, high-pressure systems and can work in any orientation.

Key differences: motion (swinging vs. axial) and application (low pressure vs. high pressure), with axial types often more compact and suitable for vertical lines.

INQUIRY