The Relationship Between Regenerative Turbine Pumps And Valves

The relationship between regenerative turbine pumps and valves is mainly reflected in their interdependence and coordination in industrial applications.

The regenerative turbine pump is a high efficiency vacuum pump that accelerates gas molecules out of the vacuum chamber through a high speed rotating turbine to achieve a high vacuum effect. This pump is usually used to handle clean liquids at or near their boiling point, such as LPG, CO2, and hot water (boiler water feed)

1.In practical applications, regenerative turbine pumps are usually used together with valves to ensure the normal operation and safety of the system.

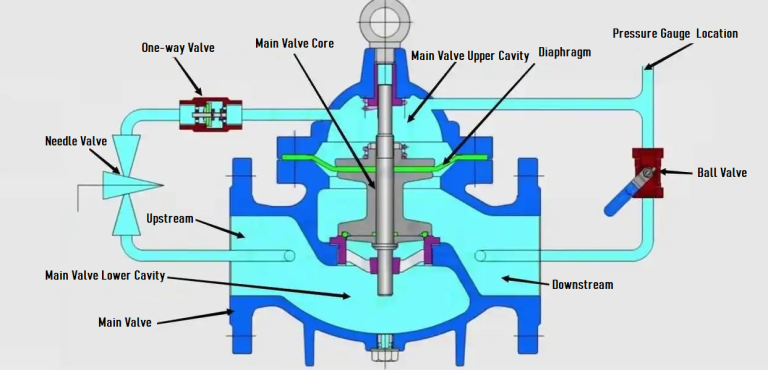

Valves play a key role in controlling fluid flow and pressure in industrial production. They can regulate fluid flow rate, change fluid flow direction, and control pipeline pressure, while also isolating pipelines and protecting equipment

2.The application of valves in the regenerative turbine pump system:

- Check Valve: prevent fluid backflow and maintain stable operation of the system.

- Throttle Valve: control fluid flow to ensure smooth operation of the system.

- Shut-off Valve: stop the pump when necessary to protect the system and equipment.

The proper use of these valves can ensure the efficiency and safety of the production process

For example, when the pressure in the pipeline is too high, installing a pressure reducing valve can reduce the pressure and avoid pipeline explosion or other safety accidents; when the fluid flow is too large, the throttle valve can control the flow and keep the system stable.