Single Disc Wafer Swing Check Valve

The single disc wafer check valve adopts a short-type structural dimension and a single-disc swing design. Compared with the traditional swing check valve, this series of valves has the advantages of no external leakage, horizontal installation, good sealing performance, small linear vibration, small pressure drop, and zero seat ring wear. When installed horizontally, the valve opening pressure of this valve is low.

The main features of single plate wafer check valve.

- Short structural length. Its structural length is only 1/4 to 1/8 of that of the traditional flanged check valve.

- Small volume and light weight. Its weight is only 1/4 to 1/20 of that of the traditional flanged check valve.

- The valve disc closes quickly, resulting in low water hammer pressure.

- It can be used in both horizontal and vertical pipelines, and is easy to install.

- The flow passage is unobstructed, with low fluid resistance.

- It is sensitive in operation and has good sealing performance.

- The valve disc has a short stroke, and the impact force when closing the valve is small.

- The overall structure is simple, compact, and aesthetically pleasing.

Technical Specifications

- Investment casting for body and disc

- Flanged ends: ANSI, DIN, JIS

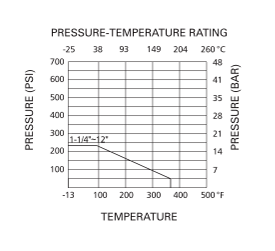

- Pressue rating: PN10/PN16/ANSI 150Lb/JIS 10K

- Woking temperature: -25°C~+ 180°C

- Material: CFSM, CFS, CF3M, WCB

- Seal: Viton/EPDM

Part Material

| ITEM | PART | MATERIAL |

| 1 | Body | F316 |

| 2 | Disc | CF8M |

| 3 | Disc O-Ring | FKM |

| 4 | External O-Ring | FKM |

| 5 | Hook | SS304 |

| 6 | Axis Stopper | SS316 |

| 7 | Axis Screw | SS316 |

Dimensions

| SIZE | d | D | D1 | H | Kgs |

| DN32 | 20 | 76 | 59 | 12 | 0.42 |

| DN40 | 25 | 85 | 68 | 12 | 0.45 |

| DN50 | 32 | 105 | 84 | 14 | 0.79 |

| DN65 | 40 | 124 | 96 | 14 | 1.10 |

| DN80 | 54 | 136 | 117.5 | 14 | 1.30 |

| DN100 | 70 | 164 | 148 | 18 | 2.26 |

| DN125 | 92 | 194 | 166 | 18 | 3.15 |

| DN150 | 114 | 220 | 197 | 20 | 4.54 |

| DN200 | 154 | 275 | 249 | 22 | 7.65 |

| DN250 | 200 | 330 | 310 | 26 | 12.63 |

| DN300 | 230 | 380 | 358 | 30 | 19.95 |

The data is for reference only, please consult sales@wayvalve.com for details.

The applications of single disc wafer swing check valve.

It is especially suitable for applications where the installation space is limited. It can be used with various media such as water, steam, oil, nitric acid, acetic acid, and strongly oxidizing media.

Which is better swing check valve or wafer check valve?

The choice between swing check valves and wafer check valves depends on specific application requirements. Swing check valves have a simple structure and are suitable for large-diameter pipelines. They can handle high-flow rates and have good sealing performance under normal conditions. However, they are relatively bulky and have a longer installation length. Wafer check valves, on the other hand, are compact and lightweight, with a short installation length, making them ideal for applications with limited space. They also have a quick-closing action, reducing water hammer effects. But they may have limitations in handling extremely high-pressure or high-temperature applications. In general, if space is a concern, wafer check valves are a better choice; for large-diameter pipelines with sufficient space, swing check valves are often more suitable.

INQUIRY