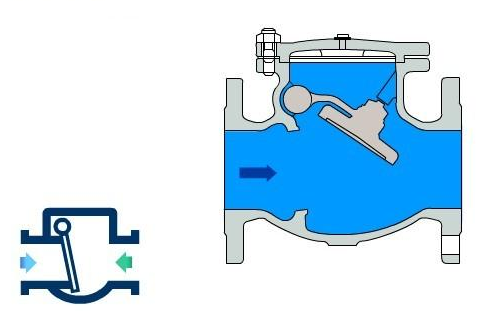

Vacuum Check Valve ANSI WCB Swing Check Valve

The vacuum check valve is mainly used in vacuum systems and needs to operate in a low-pressure or even negative-pressure environment.

In terms of structural design, in order to adapt to the vacuum environment, the vacuum check valve has higher requirements for sealing performance. It usually adopts a more precise sealing structure and high-quality sealing materials to prevent external gases or impurities from entering the vacuum system.

In addition, the opening pressure of the vacuum check valve is usually low to adapt to the pressure characteristics of the vacuum system.

Production introductions

| Type | Metal Check Valves |

| Application | Industrial |

| Power | Hydraulic |

| Structure | Shutoff |

| Customized support | OEM, ODM, OBM, Software reengineering |

| Temperature of Media | High Temperature, Low Temperature, Medium Temperature, Normal Temperature |

| Body material | Ductile Iron |

| Material | Brass/Copper/CW617N/CW614N/CW612N/C36000 |

| Connection | Flange Ends |

| Certificate | ISO9001:2008 CE |

| Size | DN40-600 |

| Working medium | Air Water Oil Gas Acid |

| Pressure | 1.6~6.4MPa |

The data is for reference only, please consult sales@wayvalve.com for details.

Main features of vacuum swing Check Valve.

The sealing surface of the vacuum swing check valve usually uses rubber or metal sealing rings to ensure the sealing performance when it is in the closed state. Its sealing performance is slightly inferior to that of the lift check valve, but it can still meet the requirements of most industrial applications.

The installation position of the vacuum swing check valve is very flexible and can be installed either on horizontal, vertical or inclined pipelines. If a vertical installation is chosen, the flow direction of the medium should be from bottom to top.

The industries where the vacuum swing check valve are applied:

Due to its compact structure, small size and light weight, the vacuum swing check valve is widely used in various industrial fields, including water supply and drainage systems, the chemical industry, heating, ventilation and air conditioning (HVAC) systems, and the shipbuilding industry, etc. It can prevent water hammer, protect the safety of equipment and personnel, prevent the backflow of condensed water, and safeguard the propulsion system of ships.

PEOPOLE ALSO ASK

How does a vacuum check valve work?

A vacuum check valve works by utilizing pressure differentials. In a vacuum system, when it is being evacuated, the vacuum pump creates a low-pressure area at the inlet of the valve. As the pressure at the inlet becomes lower than the outlet pressure, the valve opens. This allows gas or fluid to flow from the higher-pressure area (the system being evacuated) to the lower-pressure area (towards the vacuum pump). When the vacuum pump stops or the pressure conditions change, with the outlet pressure becoming lower than the inlet pressure, a spring-loaded mechanism or the force of the higher-pressure gas pushes the valve’s disc or flap to close. This prevents backflow of gas or fluid into the vacuum-maintained system, thus maintaining the vacuum integrity.

Can a vacuum check valve be used in high-temperature environments?

Yes, a vacuum check valve can be used in high-temperature environments, but certain conditions must be met. The valve’s materials, such as the body and sealing components, should be heat-resistant. Appropriate designs considering thermal expansion are needed. Also, additional cooling measures might be required. However, not all vacuum check valves are suitable, and it’s crucial to refer to the manufacturer’s specifications and choose a valve rated for the specific high-temperature range.

What is the structure of a vacuum butterfly valve?

The vacuum swing check valve is mainly composed of a valve body, a valve cover, a valve disc and a rocker. It may also include an auxiliary spring and a weight structure to improve the sealing performance. Its internal passage is streamlined, with relatively small flow resistance, and it is suitable for large-diameter scenarios with low flow rates and infrequently changing flow conditions.

INQUIRY

![[rank_math_breadcrumb]](https://wayvalve.com/wp-content/uploads/2025/03/non-slam-check-valve-768x934.jpg)