Introduction to the Lug Style Butterfly Valves.

As a common type of valve, the lug style butterfly valve has several remarkable features, which make it widely applied in industrial pipeline systems.

What is a lug type butterfly valve?

The lug butterfly valve is a type of butterfly valve featuring lugs (e.g. threaded inserts) that enable connection to pipeline flanges via bolts. The valve body’s flanges are equipped with protruding lugs, which enhance the flange’s strength and rigidity while facilitating installation and maintenance.

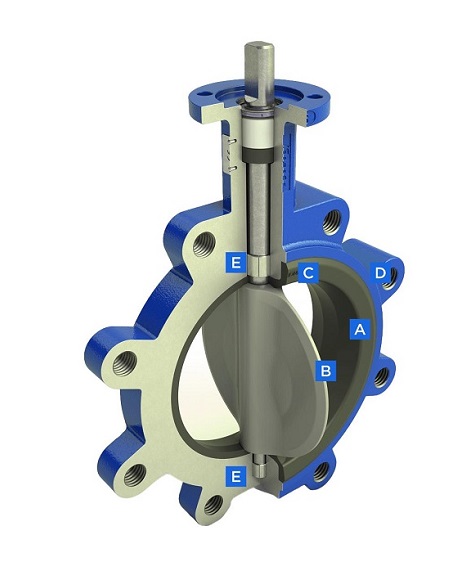

Key components of the lug type butterfly valve.

1. Seat Ring (Part A)

The seat ring is one of the key components in a lugged butterfly valve, positioned on the valve seat inside the valve body. Its primary function is to provide sealing, enabling the valve to achieve quick opening and closing during operation, thus effectively controlling the on/off state of the fluid passage. Seat rings are typically made of highly wear-resistant materials such as high-density polytetrafluoroethylene (PTFE) to ensure durability and sealing performance.

2. Valve Disc (Part B)

The valve disc is the core component in the structural diagram of a lug butterfly valve, responsible for controlling the opening and closing of the fluid passage. This component is made of a disc-shaped metal plate, usually from corrosion-resistant materials like stainless steel. The valve disc is connected to the valve stem and works in conjunction with the seat ring to achieve the valve’s opening and closing actions. The design and machining precision of the disc are crucial for the valve’s sealing performance and fluid control capability.

3. Sealing Elements (Part C)

Sealing elements are important components in lug style butterfly valves, used to prevent fluid leakage. Sealing elements typically include O-rings, sealing gaskets, packing box etc. The O-ring is located at the contact surface between the valve body and the valve stem, serving as a seal to prevent leakage. The sealing gasket is installed between the seat ring and the valve disc to ensure good sealing performance when the valve is closed, preventing medium leakage. The packing box is installed where the valve stem passes through the valve body filled with graphite or PTFE packing to prevent medium leakage.

4. Valve Body (Part D)

End-of-line capabilities are one of the important factors to consider in the structural diagram of lug style butterfly valves. This indicator represents parameters such as the valve’s pressure resistance, fluid resistance, and opening/closing torque under different working conditions. The end-of-line capabilities of lug butterfly valves must comply with relevant standards and requirements to ensure their normal operation and long-term reliability during use.

5. Bearings (Part E)

Upper and lower stem bearings are key supporting components in lug style butterfly valves, used to support the movement of the valve stem. In the structural diagram, these bearings are often made of wear-resistant and corrosion-resistant materials such as polyimide and polytetrafluoroethylene. The design and material selection of this component directly affect the smooth movement of the valve stem and sealing performance, playing a vital role in the overall reliability of the valve.

Structural characteristics of lug type butterfly valve.

- Flange Connection: The lug style butterfly valve is connected to the pipeline through a flange. This method makes the connection between the valve and the pipeline more stable, and it is suitable for medium and large-sized pipeline systems. At the same time, the flange connection also makes it convenient for the installation and disassembly of the valve, improving the convenience of maintenance.

- Lug Design: There are usually two forms on the lugs. One is a through hole (commonly known as Type A), and the other is a through hole with internal threads (known as LT type). These two designs are respectively suitable for different installation scenarios, providing more installation options.

- Double Eccentric Structure (Some Models): Some lug type butterfly valves adopt a double eccentric structure design. This design enables the valve to have relatively small friction and torque when opening and closing, thus improving the valve’s response speed and service life.

Their performance characteristics .

- Good Sealing Performance: The lug style butterfly valve usually uses a sealing gasket to ensure the sealing performance. Some models also have a triple sealing structure (two layers of seals and one layer of metal seal), which can maintain good sealing performance under high temperature, high pressure and corrosive media.

- Quick Opening and Closing: The lug type butterfly valve can be opened and closed quickly, enabling rapid control of the passage and interruption of the medium, and improving the operation efficiency of the pipeline system.

- Strong Corrosion Resistance: The valve body and valve disc are made of materials such as stainless steel (SS304, SS316, SS304L, SS316L, etc.), making the lug type butterfly valve have good corrosion resistance and be applicable to a variety of medium environments.

- Easy to Operate: The lug type butterfly valve is easy to operate and control. Some models are also equipped with reliable operating handles and electric devices, ensuring precise control and convenient remote operation.

Other characteristics of lug style butterfly valves.

- Novel and Reasonable Design: The lug type butterfly valve has a novel and reasonable design, a compact structure, and a light weight, making it easy to carry and install.

- Replaceable Sealing Parts: The sealing parts of the lug type butterfly valve can be replaced, which ensures the sealing performance of the valve during long-term use.

- Flow Characteristics Tend to be Linear: The flow characteristics of the lug type butterfly valve tend to be linear, which gives it better accuracy and stability when regulating the flow rate of the medium.

Lug vs wafer butterfly valve.

1.What is a wafer butterfly valve?

The disc of a wafer butterfly valve is installed in the diameter direction of the pipeline. The disc rotates around the axis, with a rotation angle between 0° and 90°. When it rotates to 90°, the valve is in the fully open state. Wafer butterfly valves are generally installed horizontally. They have a simple structure, a small volume, and a light weight, consisting of only a few components. And it can be quickly opened and closed by rotating 90°, with simple operation. At the same time, it has good fluid control characteristics. When the butterfly valve is in the fully open position, the thickness of the disc is the only resistance when the medium flows through the valve body. Therefore, the pressure drop generated through this valve is very small, so it has better flow control characteristics.

2.Differences between a lug butterfly valve and a wafer butterfly valve.

①Differences in connection methods.

Lug butterfly valves differ from wafer butterfly valves in their connection methods. Lug butterfly valves offer more diverse connection types compared to wafer butterfly valves.

Common wafer butterfly valves are equipped with four bolt holes. During installation, they only need to be connected by passing long bolts through the flange holes of the pipeline and the wafer butterfly valve, and then fastening the valves with nuts. It makes the installation and disassembly very convenient. However, one drawback is poor stability.

While lug butterfly valves have two connection methods. The bolt holes on lug can be divided into through-type pressure holes and threaded pressure holes.

- Through-type pressure holes: Similar to wafer butterfly valves in installation method, with slightly better stability, but still inferior to flanged butterfly valves.

- Threaded pressure holes: The installation method differs from both wafer and flanged butterfly valves. Each pressure hole is threaded. When connecting to the flange on the pipeline, the bolt passes through the flange plate drilling into the threaded hole and is tightened and fixed like screwing a screw.

②Disparities in sealing performance.

- In terms of sealing performance, lug style butterfly valves feature direct flange connection, ensuring uniform bolt force and maintaining stable sealing in medium and low-pressure environments.

- Wafer butterfly valves rely on the clamping force of flanges. If improperly installed, they are prone to uneven pressure and leakage. However, they have stronger adaptability to standard flanges and are suitable for general fluid control.

- Cost Differences.

③Cost differences.

From a cost perspective, wafer butterfly valves have a price advantage as they eliminate the valve body flange, while lug butterfly valves are favored in industrial scenarios requiring high reliability due to their stable structure. Both types feature fast opening/closing and low flow resistance, but users should flexibly choose according to pipeline pressure, installation conditions, and maintenance needs to achieve ideal control effects and economic benefits.

Summary: advantages and cisadvantages of lug style butterfly valves in practical applications.

Advantages:

- Stable flange connection for medium to large pipelines, enabling easy installation, maintenance, and disassembly.

- Versatile lug designs (e.g., through-holes with/without threads) offer flexible mounting options.

- Good sealing performance, often with triple-seal structures, suitable for high-temperature, high-pressure, and corrosive media.

- Quick operation (90° rotation for full open/close) and low friction/torque (in dual-eccentric models), improving efficiency and lifespan.

- Corrosion resistance due to materials like stainless steel, suitable for diverse media environments.

- Compact, lightweight design with replaceable seals, ensuring long-term reliability and easy repair.

- Linear flow characteristics for precise flow regulation.

Disadvantages:

- Require more space and bolts for flange installation compared to wafer types, potentially increasing installation time and cost in some cases.

- Generally more complex and heavier than wafer-style butterfly valves, making them less ideal for very small pipelines or lightweight systems.

Lug butterfly valves indeed perform remarkably in high-pressure environments. The double-eccentric structure can reduce disc wear by 80%, while the flange engagement withstands higher pressure—these are the keys for industrial pipeline selection.