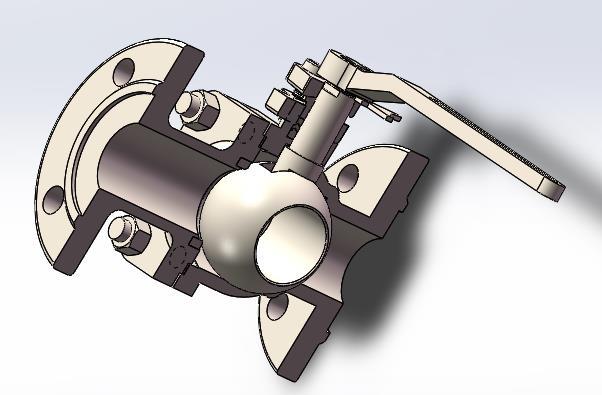

Pneumatic Control V Ball Valve

The V port ball valve is a special type of ball valve. Its core features a V-shaped notch. This design enables the V ball valve to perform excellently in flow regulation and controlling. The V ball valve belongs to the fixed ball valve category and has a single-seat sealing structure. Its flow characteristic is equal percentage, and the adjustable ratio reaches 100:1.

A pneumatic V ball valve combines the features of a pneumatic actuator and a V ball valve. It is mainly used to control the flow of media such as liquids, gases, and steam. It receives control signals through the pneumatic actuator to achieve rapid response and automated control.

Main features of the v-port ball valve.

Body:

- Integral body design offers greater rigidity against fluctuating pipe loads.

- Eliminates the leak path associated with two piece body designs.

- Both wafer and flange connection are available.

Core:

- Specially designed V-notch ball provides strong cutting stress and tight sealing.

- Hard chromium, nitriding, and HCOF treatments are all available for the ball surface treatment, improving hardness, abrasion resistance, fatigue resistance, corrosion resistance and performance under high temperature.

- Well ground notched ball surface ensures small operating torque and tight seal, especially for metal seated segment valve.

Seat:

- For valve rated under class 150, retainer is casted on valve body to eliminate any possible space between seat ring and body for residue accumulation. Consequently, this ensures perfect seal。

- Specialized spring design decreases valve torque while providing force for tight sealing.

- Pressure energized seat design offers excellent sealing even at very low differential pressures.

Stem:

The stem is finely ground to match the actuator excellently, which prevents rocking motion and potential failure of the segmented valve.

Specification

| Size Range: | DN 25~250mm NPS 1”-10” (Wafer) DN 25~500mm NPS 1”-20” (Flange) |

| Press. Rate: | PN 10/16/25/40/63 ANSI 150/300/600 |

| Temp. Range: | Metal Seat -29…+450℃ Resilient Seat -29…+150℃ |

| Seal Tightness: | Metal Seat Class IV Resilient Seat Class VI |

| Body Material: | Carbon Steel, Stainless Steel, Special Alloy |

| Ball/Stem Material: | Stainless Steel, Special Alloy |

| Seat Material: | Stainless Steel+STL, PCTFE,PEEK (Flange) Stainless Steel+STL (Wafer) |

| Face to Face: | ISA S75.04, IEC/DIN 534-3-2 (Flange) Factory Standard (Wafer) |

| Flange Standard: | GB/T 9113.1, JB/T 79.1, HG 20592, ASME B 16.34, ISO 7005 (Other drilling on request) |

| Appliactions: | Pulp & Paper,Water Treatment,Food & Beverage, Fine Chemical,Power Plant,Steel Industry |

The data is for reference only, please consult sales@wayvalve.com for details.

Pneumatic V-ball valves are widely used in multiple industrial sectors, including:

Chemical industry: They are used for controlling media such as liquids and gases.

Petroleum industry: They are employed for controlling media like oil products and natural gas.

Food industry: High – quality stainless steel and other materials are selected for the valves, which comply with food hygiene standards.

Pharmaceutical industry: The valves meet the hygiene standards of the pharmaceutical industry and are used for controlling media during the drug production process.

What is the difference between V-port and full port ball valve?

The main difference are their valve core design and application. A V-port ball valve has a V-shaped notch on the valve core. This design allows it to perform well in flow regulation, with an equal-percentage flow characteristic and a high adjustable ratio (up to 100:1), making it suitable for precise control of media flow.

In contrast, a full-port ball valve has a large, unobstructed passage through the ball. This results in minimal flow resistance, and it’s mainly used for on-off applications where full flow is required and pressure drop needs to be minimized.

INQUIRY