Why Ball Check Valve is Better for A Sewage Lifting Device?

Sewage lift devices are mainly used for the collection and lifting of sewage in buildings. The composition of sewage in buildings is relatively complex: feces, toilet paper, various kitchen wastes, etc., are all mixed in it. These wastes are discharged into municipal pipelines through the sewage pump of the sewage lift device. Each sewage lift device is equipped with a check valve at the outlet to prevent sewage from flowing back into the collection tank after being pumped out. This not only improves the drainage efficiency, but also prevents the water pump from being driven to reverse by the backflow sewage, which may damage the motor of the water pump. Therefore, equipping a durable and reliable check valve is a very important link in the sewage pumping process.

Classification of commonly used check valves:

At present, there are generally two kinds of check valves commonly used in the market: one is the plate-type check valve, and the other is the ball type check valve. So what are the characteristics of these two kinds of check valves?

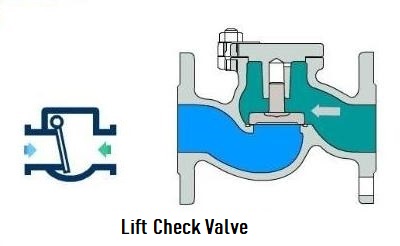

Flap check valve:

Advantages.

This kind of check valve is the most common configuration of sewage lift devices at present. It has the characteristics of simple structure and low price, and can cope with most working conditions. The flap adopts a structure with a built-in iron core and rubber coating. The rubber coating on the flap is pressed against the base to achieve sealing and check functions.

Disadvantages.

The sealing surface of this kind of check valve is fixed. If there are some sundries remaining on the sealing surface, it will directly affect its sealing effect. Moreover, under the continuous action of the sealing plate, the sealing surface with residual sundries is very easy to be damaged. In addition, water hammer will be generated every time the sealing plate falls, which will affect the service life of the check valve to a certain extent. However, its advantage is that the structure is simple, and most of the materials are engineering plastics, so the cost is relatively low. Therefore, this kind of check valve is mostly used in entry-level sewage lift pumps.

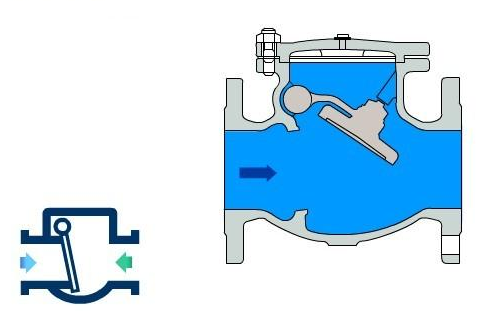

Ball check valve:

During the use of the ball check valve, the ball will keep rolling with the water flow and continuously roll over the sealing surface. If there are sundries adhering to the sealing surface, the ball will remove them in the first place. That is to say, the ball has a cleaning effect on the sealing surface, ensuring the effectiveness of the seal. Moreover, the ball valve is evenly stressed during use, with a solid structure and is less likely to be damaged. The ball check valve is the most effective check valve used in the sewage industry, so without exception, high-end sewage lift devices all use ball check valves.

The advantages of ball check valves are specifically as follows:

- The ball check valve has the characteristics of large flow and small resistance;

- The ball valve will roll evenly during the flow of fluid, which is especially suitable for discharge pipelines of industrial and domestic sewage containing suspended solids;

- The ball valve can effectively clean the channel and sealing surface during rolling, which has the function of cleaning the sealing surface;

- The check valve closes in a silent manner during the closing process, which will not generate water hammer, can better protect the sealing surface, and has a longer service life;

- The valve core of the ball check valve has no transmission parts and is of a free opening and closing structure, so there is no wear of the transmission shaft. The ball automatically rotates and rolls in the spherical pipeline, constantly updating the sealing surface, and there is no fixed wear point;

- Since there are many sundries in the sewage, during long-term use, if the spherical surface is worn, it will only be worn evenly, and will always maintain high shape accuracy without affecting the sealing effect;

- Since the valve core adopts a structure of a hollow iron ball covered with rubber, the check valve has certain elasticity during use, which can play the role of vibration absorption and damping;

- In addition, the sealing surface of the spherical structure is relatively narrow, the sealing pressure is relatively large, and the sealing effect is better.

From the above characteristics, it can be seen that the ball check valve is the best choice in the process of sewage pumping and the best configuration in the sewage lift pump configuration. High-end sewage lift pumps are standard equipped with ball check valves to ensure the best effect and the longest service life in sewage pumping.