How Should the Air Compressor Check Valves be Installed?

What is the function of the air compressor check valves?

The compressor check valve is a kind of one way valve that prevents the reverse flow of gas.Its main function is to prevent the gas from flowing backward after the compressor stops operating, and thus avoid causing damage to the components of the compressor so as to protect it. Depending on its design in structure, the check valve allows gas to flow smoothly in the forward direction, and it will automatically close when there is a reverse flow, thus restricting the backflow of gas.

How does a air compressor check valve work?

The check valve usually adopts a spring-type design. When the gas flows in the forward direction, the spring is compressed and the valve opens, allowing the gas to pass through smoothly. When the gas flows in the reverse direction, the spring rebounds and the valve is forced to close, thereby preventing the gas from entering the compressor.

The types and applications of air compressor check valves.

Check valves can be classified in various ways according to their structures and uses, including:

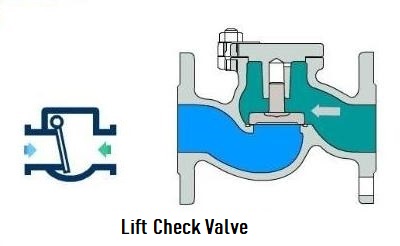

- Lift check valves: They rely on the pressure of the medium to open and close, and are often used in small-diameter pipelines.

- Swing check valves: They utilize the combined action of the medium pressure and gravity to close, and are suitable for larger pipelines.

- Spring check valves: They achieve the one-way blocking function through the design of the spring.

When selecting a check valve for air compressor , it is necessary to make a judgment according to specific requirements to ensure that its structure and function are in line with the actual usage scenario.

Why we have to install an air check valve for air compressor ?

Three reasons for installing a check valve for air compressor.

- Safety Guarantee: When the air compressor stops, there is still high-pressure gas inside the system. Without a check valve, the gas may flow back into the compressor, causing damage to the equipment and even a safety accident.

- Extended Service Life: The internal mechanical structure of the air compressor is complex and is affected by high-pressure gas. Backflow will cause the equipment to vibrate and damage the components. Installing a check valve helps to reduce this risk.

- Enhanced Stability: The check valve ensures the consistency of the gas flow direction, reduces deviations, and thus improves the stability and efficiency of the air compressor operation.

How to install an air compressor check valve?

Installation location of inline check valve for air compressor.

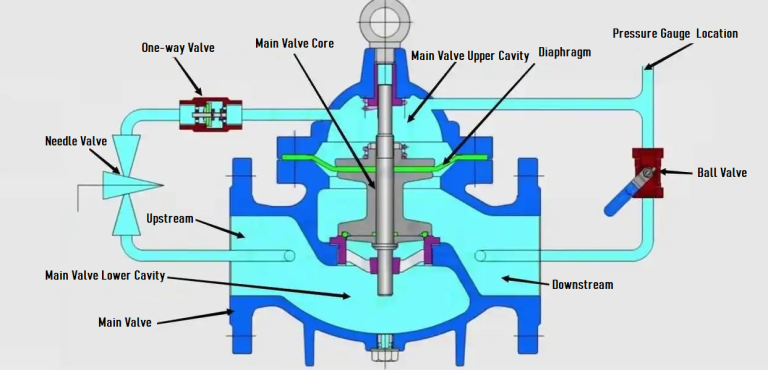

First where is the check valve on an air compressor? To install at the outlet of the unit. A check valve should be installed on the intake pipeline of the air compressor. If this pipeline is connected to other gas sources and cannot be further expanded, a check valve must be installed at this position.

Installation direction of the check valve for air compressor.

The inline check valve for air compressor must be installed in the vertical direction. During the installation process, horizontal or inclined installation should be avoided to ensure its normal operation. At the same time, for compressors with a horizontally placed gas source inlet, it is necessary to specially confirm the installation position and direction of its check valve.

Precautions for installing the check valve for air compressor.

- Before installation, check whether the air compressor is in normal condition and stop its operation.

- When installing the inline check valve for air compressor, operate according to the requirements of the instruction manual to ensure that the installation direction and position are correct.

- During the installation process, deal with the pipeline joints. A tight connection of the pipeline can ensure the normal operation of the valve.

Here below are also some frequently asked questions:

What does the check valve do on an air compressor?

A check valve on air compressor serves two main purposes. First, it prevents the backflow of compressed air from the air storage tank or the delivery line back to the compressor when the compressor stops running. This helps maintain the pressure in the system and prevents the air from escaping. Second, it ensures that the air flows in only one direction, from the compressor to the storage tank or the intended destination, which helps the air compressor operate efficiently and reliably.

Can you run a compressor without a check valve?

Yes, you can run a compressor without a check valve, but it’s not recommended. Without a check valve:

Air Backflow: Compressed air will flow back into the compressor when it stops, causing inefficiency and potential damage.

Loss of Pressure: The storage tank will lose pressure, requiring the compressor to restart frequently, increasing wear and energy consumption.

Safety Risks: Backflow might damage components like the pump or motor.

In short, while possible, operating without a check valve compromises performance, longevity, and safety. Always use a check valve for proper compressor function.

How do you know if your air compressor valve is bad?

Signs of a faulty air compressor check valve include:

Slow Pressure Build-Up: Takes longer to reach max pressure.

Pressure Drop: Tank loses pressure when the compressor is off.

Continuous Cycling: Compressor runs more frequently.

Air Leak Noise: Hissing sound near the valve.

Overheating: Valve or motor overheats due to strain.

Failed Start: Compressor struggles to start due to backflow.

If you notice these issues, inspect the valve for debris, damage, or wear, and replace it if necessary.

How do you clean a air compressor check valve?

To clean a inline check valve for air compressor:

Safety First: Turn off the compressor, disconnect power, and release all pressure from the tank.

Locate & Remove the Valve: Find the valve (usually near the pump or tank) and unscrew it using wrenches.

Disassemble: Separate the valve components (spring, disc, seat). Note their order for reassembly.

Clean: Soak parts in a degreaser or vinegar to dissolve debris/rust. Use a brush or compressed air to clear stubborn buildup.

Inspect: Check for damage (cracks, wear). Replace worn parts if needed.

Reassemble & Reinstall: Put the valve back together in the correct order and tighten it securely.

Test the compressor for restored functionality. Cleaning prevents clogs and ensures proper airflow.