A Brief View of Well Pump Check Valve

What is a well pump check valve?

A water well pump check valve is a one way valve used to prevent the backflow of water, mainly installed at the outlet of the water well pump. Its main function is to ensure that water can only flow in one direction and prevent water from flowing back from the water well into the pump, thus protecting the normal operation of the pump and extending its service life.

Operation principle of the well pump check valve.

The pump check valve automatically opens and closes relying on the flowing pressure of the medium itself. When water flows from the water well into the pump, the pressure of the water flow pushes the valve disc open, allowing the water to be pumped out normally. When the pump stops working or the direction of the water flow is reversed, the pump check valve’s disc automatically closes under the action of its own weight and the pressure of the fluid, thereby preventing the backflow of water.

Structural Types of check valve for water pump.

Check valve for well pumps are mainly divided into the following categories:

- Lift check valve: The valve disc slides along the vertical centerline of the valve body. It is suitable for small-diameter pipelines, but the fluid resistance is relatively large.

- Swing check valve: The valve disc is in the shape of a disc and rotates around the rotating shaft of the valve seat passage. It is suitable for large-diameter pipelines and has relatively small fluid resistance.

- Butterfly check valve: The valve disc rotates around the pin shaft inside the valve seat. The structure is simple, but the sealing performance is poor.

The selection of the installation position of the deep well check valve in the water well system.

Normally the deep well check valve should be installed above the water level to avoid the pollution of the water and the problem of backflow, and at the same time ensure the convenience of valve maintenance.

The check valve for water pump is usually installed above the water outlet of the pump (behind the water pump) or at the lower end of the vertical suction pipe (at the position of the foot valve), specifically depending on the relative position between the water pump and the liquid level.

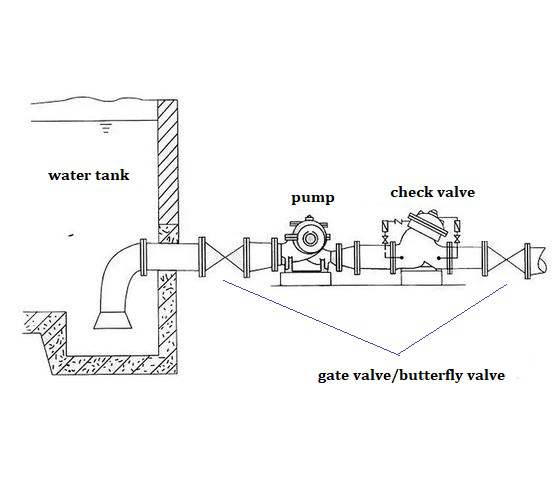

- Installed behind the water well pump (installed above)

When the liquid level of the well is higher than the water pump (such as in a secondary water supply system), the check valve should be installed above the water outlet of the water pump, in front of the outlet control valve (such as a gate valve or a butterfly valve). This installation method can prevent the backflow of water when the pump stops, and it is also convenient for the maintenance of the pump check valve. Usually, the sequence is: water pump → flexible connection (shock absorber) → water pump check valvecheck valve → isolating valve.

Advantages:

There is no need to fill water before starting the pump each time when the liquid level is higher than the water pump;

It is suitable for the header pipe system and can prevent the backflow problem when multiple pumps are connected in parallel.

When installed at the water outlet of the water well pump, it is recommended to install isolating valves before and after the well check valve for convenient maintenance. - At the lower end of the vertical suction pipe (foot valve, installed below)

When the installation position of the water pump is higher than the liquid level (such as pumping water from a well), a foot valve (a special check valve for well pump) needs to be installed at the lower end of the vertical suction pipe. Its function is to keep the pump and the suction pipe filled with water and avoid manual water filling before each start.

Features:

It belongs to the lift check valve and needs to be installed strictly vertically;

It is suitable for the “negative pressure method” water pumping, but the head loss is relatively large.

Key precautions about water well pump check valve.

Action for maintenance convenience:

Whether installed above or below, the arrow direction of the check valve must be consistent with the direction of the water flow, and the valve disc must be able to close automatically under the action of gravity.

Types selection:

The swing check valve is suitable for horizontal or vertical pipelines, but it should be noted that water hammer may occur in large-diameter pipelines;

The lift type water well check valve(foot valve) is only suitable for small-diameter vertical suction pipes.

Summary of the selection of well pump check valve installation position.

When the liquid level is higher than the water pump → install the check valve above the water outlet of the water pump;

When the water pump is higher than the liquid level → install a foot valve at the lower end of the vertical suction pipe and ensure the sealing performance.

![[rank_math_breadcrumb]](https://wayvalve.com/wp-content/uploads/2025/03/non-slam-check-valve-768x934.jpg)