What is a Ball Valve, and its Applications.

What is a ball valve?

A ball valve is a type of ball shutoff valve that is widely used in various industries for fluid control. Here is a detailed introduction:

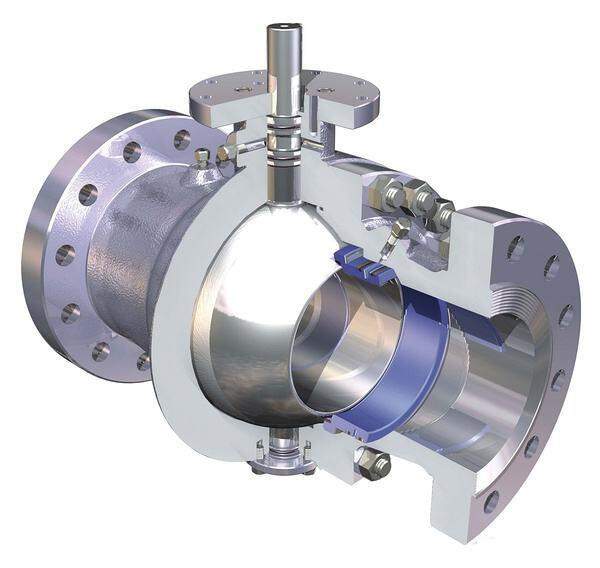

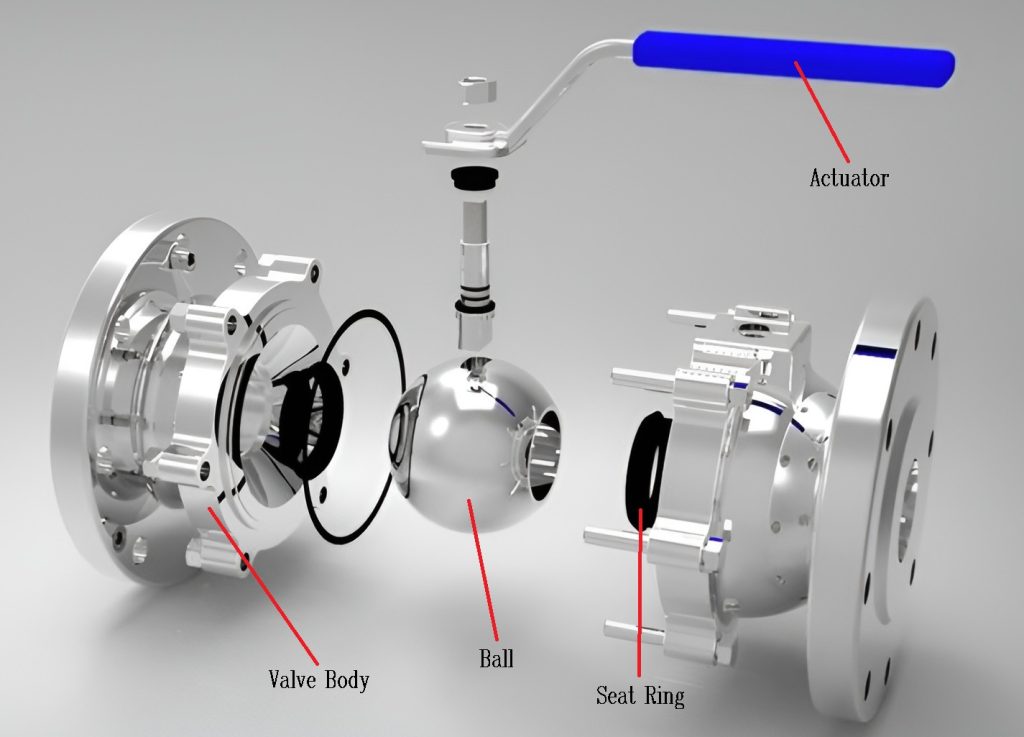

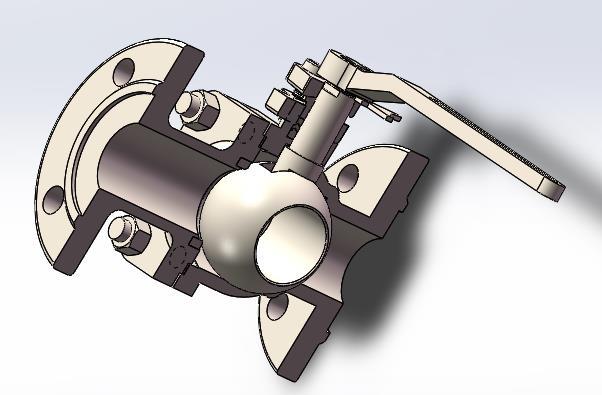

1.Diagram of a ball valve

- Ball: The core component is a spherical ball with a circular through-hole in the middle. The ball is usually made of materials such as stainless steel, copper alloy, or plastic, which have good corrosion resistance and wear resistance.

- Seat Ring: Located at both ends of the ball, the seat ring is in contact with the ball to form a sealing surface. It is usually made of materials with good sealing performance, such as PTFE (polytetrafluoroethylene) or rubber, to ensure reliable sealing when the valve is closed.

- Valve Body: The valve body houses the ball and seat ring and provides connections to the pipeline. It is usually made of cast iron, carbon steel, or stainless steel to withstand different working pressures and media.

- Actuator: The actuator is used to drive the rotation of the ball and can be manual, pneumatic, hydraulic, or electric. Manual actuators are usually operated by a handle or wrench; pneumatic and hydraulic actuators use compressed air or hydraulic oil as the power source; electric actuators use electric motors to drive.

2.Working principle

- Opening: When the ball valve is opened, the through-hole in the ball is aligned with the pipeline, allowing fluid to flow through the valve with minimal resistance. The ball rotates around its axis, and when the through-hole is completely in line with the flow direction of the pipeline, the valve is in the fully open position.

- Closing: To close the ball valve, the ball is rotated 90 degrees so that the through-hole is perpendicular to the pipeline, blocking the flow of fluid. The seat ring presses against the surface of the ball to form a seal, preventing fluid leakage.

3.Advantages and disadvantages

Positive features:

- Low flow resistance: When the ball valve is fully open, the fluid can flow through the through-hole in the ball with almost no obstruction, resulting in very low flow resistance and energy loss.

- Quick opening and closing: The ball can be rotated 90 degrees to achieve full opening or closing, and the operation is simple and fast, which can meet the needs of quick response in some occasions.

- Good sealing performance: The contact between the ball and the seat ring forms a tight seal, which can effectively prevent fluid leakage. Even after long-term use, the sealing performance is still reliable.

- Wide range of applications: It can be used to control various fluids, including water, oil, gas, chemical media, etc., and is suitable for different working pressures and temperatures.

Negative features:

- Limited throttling capability: Although the ball valve can adjust the flow to a certain extent, its throttling accuracy and control performance are not as good as those of some other valves, such as globe valves.

- High cost: Compared with some simple valves, the manufacturing process of ball valves is relatively complex, and the cost of materials and manufacturing is relatively high, especially for ball valves with special materials and high-pressure resistance requirements.

- Not suitable for fine particle media: In the case of media containing a large number of fine particles or fibrous substances, the ball and seat ring of the ball valve are prone to wear and scratching, which will affect the sealing performance and service life of the valve.

What are the applications of ball valves.

There are mainly the following fields:

- Residential and commercial plumbing: In water supply and drainage systems, ball valves are commonly used to control the water supply to faucets, toilets, and other water-using equipment. They are also used in heating and cooling systems to adjust the flow of water or refrigerant.

- Industrial pipelines: In the petrochemical, oil and gas, power, and other industries, ball valves are widely used in pipelines to control the flow of various fluids. For example, in oil and gas transmission pipelines, ball valves are used to quickly cut off the flow in case of emergencies; in chemical reaction systems, ball valves are used to control the addition and discharge of raw materials and products.

- Marine and offshore engineering: Ball valves are used in the piping systems of ships and offshore platforms to control the flow of seawater, oil, and gas. They need to have good corrosion resistance and pressure resistance to adapt to the harsh marine environment.