What is a Butterfly Valve, and Its Applications.

What is a butterfly valve?

A butterfly valve is a type of valve widely used in fluid control systems. Here is a detailed introduction:

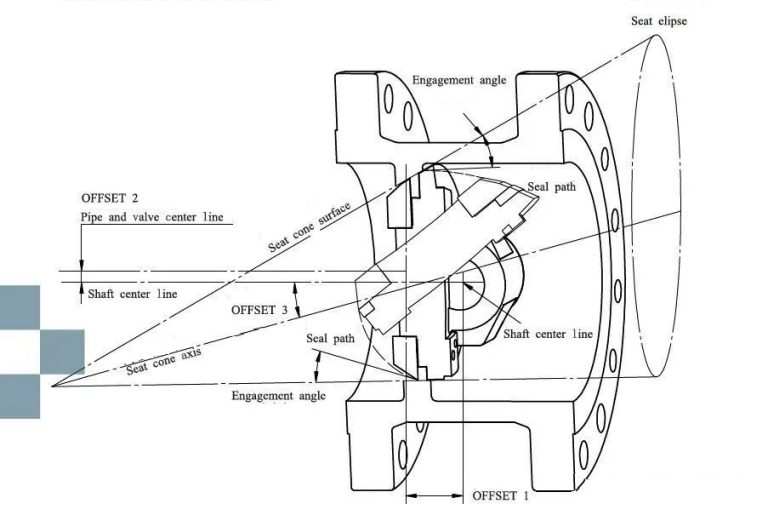

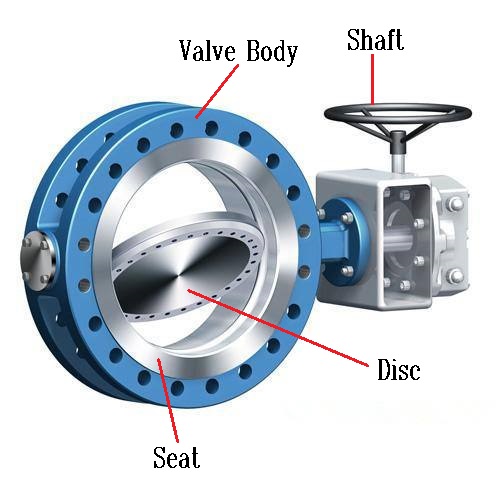

1.Structure

Disc: The disc is the core component of the butterfly valve, which is usually a circular plate. It is located in the center of the pipe and rotates around the shaft to control the fluid flow. The disc is generally made of metal materials such as stainless steel and cast iron, and can also be made of non-metallic materials such as plastic according to different application scenarios.

Shaft: The shaft is connected to the disc and is used to drive the rotation of the disc. It is usually made of high-strength alloy steel to ensure sufficient strength and stability to withstand the torque and force during the opening and closing of the valve.

Seat: The seat is located on the inner wall of the valve body and contacts with the disc to form a seal when the valve is closed. The seat material is usually PTFE (polytetrafluoroethylene), rubber or other materials with good sealing performance and corrosion resistance.

Valve Body: The valve body is the shell of the butterfly valve, which is used to install components such as the disc, shaft and seat, and connect with the pipeline. The valve body is usually made of cast iron, carbon steel, stainless steel and other materials to adapt to different working pressures and media.

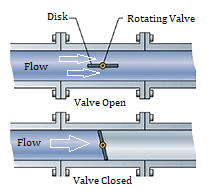

2.Working principle

Opening: When the butterfly valve is opened, the disc rotates around the shaft to a position parallel to the fluid flow direction, so that the fluid can pass through the valve with little resistance.

Closing: To close the butterfly valve, the disc rotates 90 degrees around the shaft until it is perpendicular to the fluid flow direction, blocking the fluid passage. The seat and the disc fit closely to achieve sealing and prevent fluid leakage.

3.Advantages and disadvantages

Positive features

- Lightweight and compact: Compared with some other types of valves, butterfly valves have a relatively simple structure, are lightweight and occupy less space, which is convenient for installation and maintenance in limited space.

- Low flow resistance: When the butterfly valve is fully open, the disc is almost parallel to the fluid flow, resulting in low flow resistance and small energy loss, which is beneficial to saving energy and improving system efficiency.

- Quick opening and closing: The disc of the butterfly valve can complete the opening and closing action by rotating 90 degrees, and the operation is simple and quick, which can meet the requirements of rapid response in some occasions.

- Wide range of applications: It can be used to control various fluids, including water, air, gas, oil and some chemical media, and is suitable for different working pressures and temperatures.

Negative features

- Limited sealing performance: Although the butterfly valve has good sealing performance under normal conditions, it may have poor sealing performance under high pressure and high temperature conditions or when dealing with some high-viscosity and granular media, and is prone to leakage.

- Not suitable for fine flow regulation: The flow regulation accuracy of the butterfly valve is relatively low and is not suitable for occasions that require precise control of fluid flow, such as some high-precision chemical reaction processes.

- Sensitive to installation: The installation position and method of the butterfly valve have a great influence on its performance. If the installation is improper, it may lead to problems such as unbalanced force on the disc and poor sealing performance.

The applications of butterfly valves.

There are mainly the following fields:

- Water supply and drainage systems: In urban water supply and drainage projects, butterfly valves are widely used to control the flow of water in pipelines, such as in water treatment plants, water distribution networks and sewage discharge systems.

- HVAC systems: In heating, ventilation and air conditioning systems, butterfly valves are used to adjust the flow of air and water, so as to realize the control of temperature, humidity and air volume in the building.

- Chemical industry: In chemical production, butterfly valves are used to control the flow of various chemical media in pipelines, such as in the transportation and reaction processes of acids, alkalis and organic solvents.

- Power industry: In power plants, butterfly valves are used in cooling water systems, steam systems and other pipelines to control the flow of working fluids and ensure the normal operation of the power generation equipment.