Valve Sourcing: Ball Valve vs Gate Valve

Ball valve and gate valve are two of the most commonly used valves for controlling the flow of fluid in plumbing or gas systems. These valves have similarities in application, but have different strengths to offer. This guide reviews the key differences between ball valves vs. gate valves, giving you the reference to choose the best type of valve for your needs.

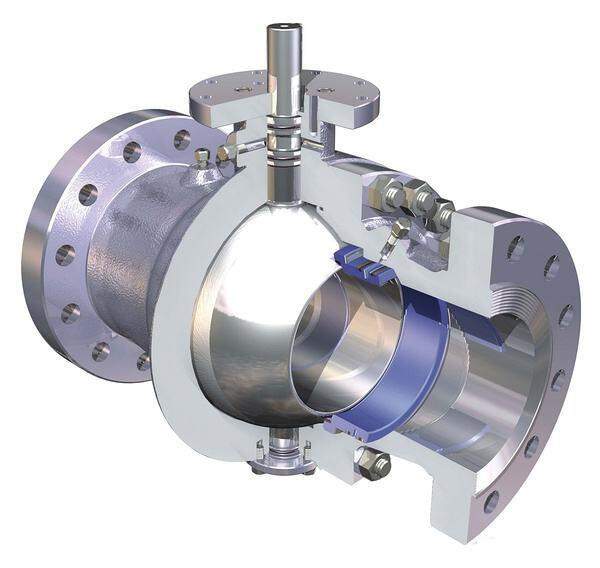

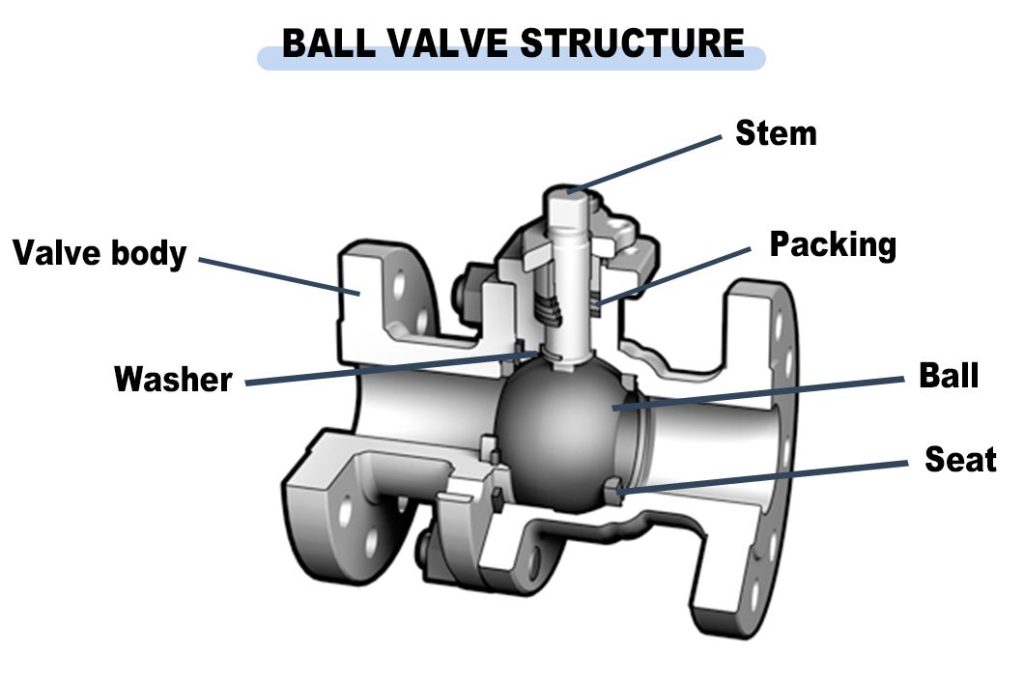

Ball Valve

Ball valves are shut-off valves used to allow or obstruct the flow of fluids by rotating the ball having a bore inside it by 900. They can be operated manually or by an actuator. Ball valves consist of the ball, shaft, and seat which are contained in the valve housing.

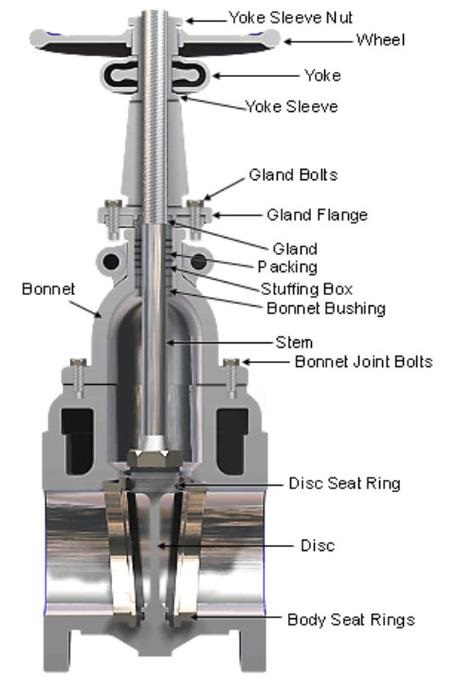

Gate Valve

A gate valve, also known as a sluice valve, is a valve that opens by lifting a barrier (gate) out of the path of the fluid. Gate valves require very little space along the pipe axis and hardly restrict the flow of fluid when the gate is fully opened.

Gate valves allow you to control the rate of the flow of water, from a slow trickle to a full flow, but don’t provide an immediate stop. They are usually controlled by a manual handwheel that requires more than a 360-degree turn to change the gate’s position.

Ball Valve vs Gate Valve

Now that you know the differences between ball valves and gate valves, we can compare other factors between them.

- Cost: Gate valves tend to be more wallet-friendly than ball valves

- Reliability: Gate valves are more susceptible to corrosion. Over time, the internal stem that connects the knob to the gate becomes more likely to fail.

- Frequency of use: Since gate valves wear out quicker, they are often found in applications where they don’t need to be adjusted very often. Ball valves are recommended for applications that require frequent, quick control over the flow of liquid.

- Space: Ball valves are smaller than gate valves, but the size of their levers means that they require more space for proper operation

- Number of ports: If your application calls for a multi-port flow pattern, then a ball valve will likely be your choice because they are much more widely available in multi-port configurations

- Water hammer: Because ball valves can open and close immediately, they are more likely than gate valves to cause water hammer. When a valve is quickly closed on water moving at high pressure through pipes, it can cause shock waves through the plumbing that create a hammering sound. Under high enough pressure, a water hammer can cause a pipe to weaken and break. For that reason, users are advised to turn the ball valve lever slowly to avoid water hammer.

Since gate valves and ball valves have different strengths, you can find each commonly used in different industries. Gate valves often turn up in large water supply lines, mining and power plants. You’ll see ball valves being used in places like the automotive industry, manufacturing facilities and in food and beverage equipment.

Choosing between the different types of valves for your plumbing or gas system can mean weighing options such as cost, reliability and technical differences. Ball valves and gate valves provide similar functions while offering different levels of control.