How do Hydraulic Valves and Hydraulic Pumps Work Together?

Hydraulic valves and hydraulic pumps are important components of hydraulic systems. The coordinated operation between them plays a vital role in the normal operation of the entire hydraulic system. The following will introduce in detail how hydraulic valves and hydraulic pumps work together.

Ⅰ. Function of hydraulic pump.

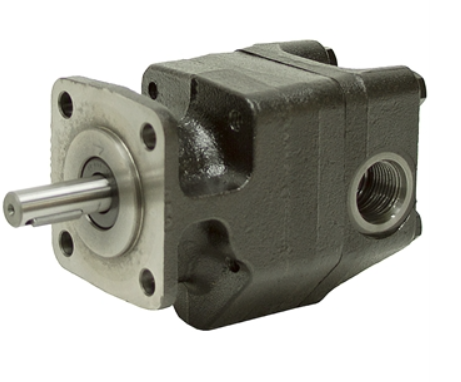

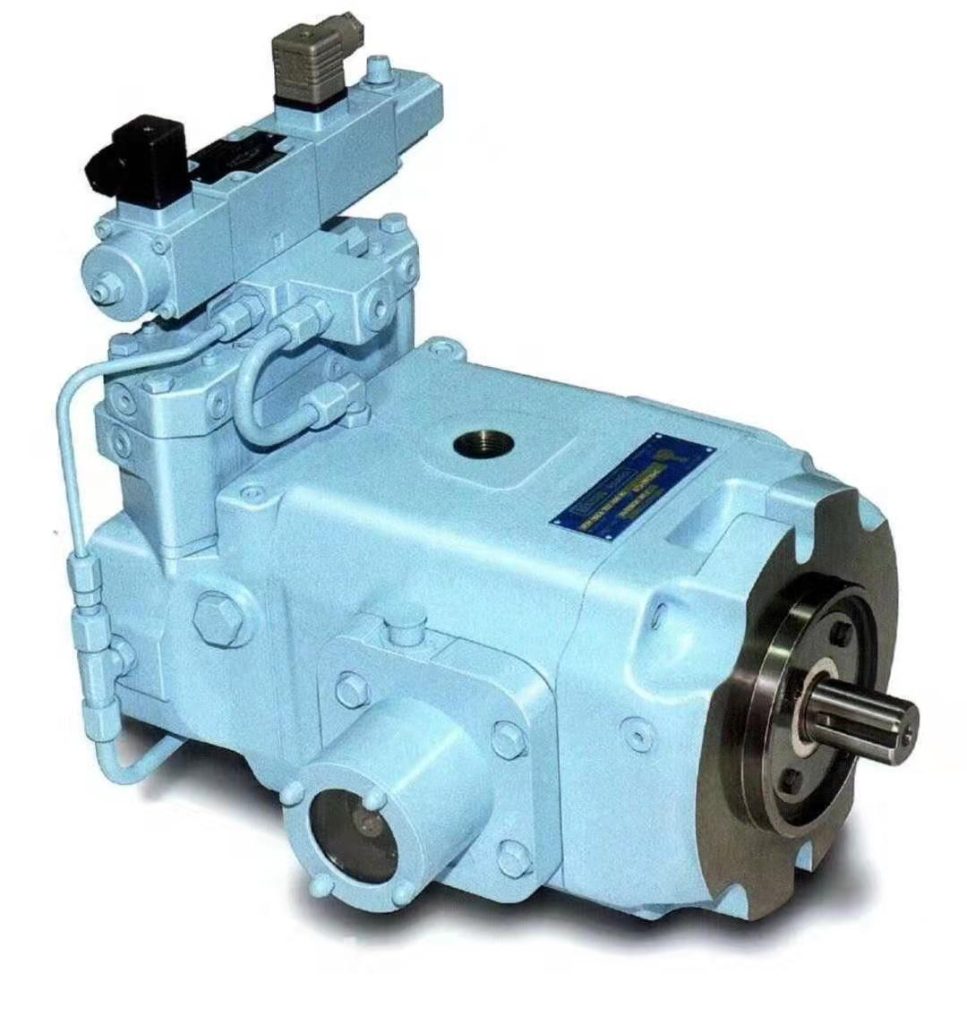

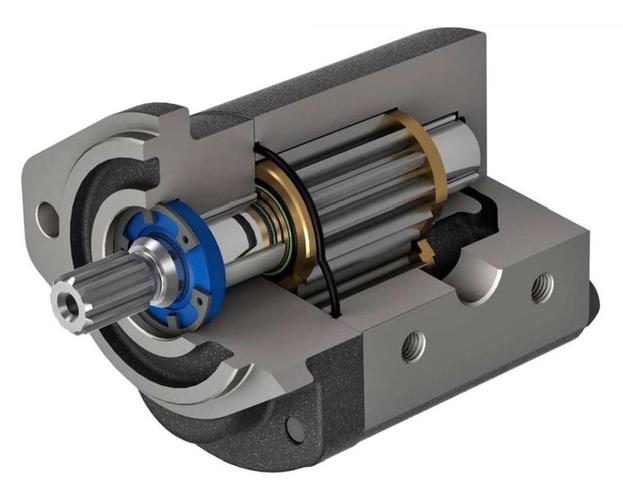

Hydraulic pump is the power source of hydraulic system. Its main function is to convert mechanical energy into hydraulic energy and provide hydraulic oil with a certain flow and pressure for the system. There are many types of hydraulic pumps, such as gear pumps, vane pumps, plunger pumps, etc. Their working principles and structural characteristics are different, but the basic principle is to suck liquid from the low-pressure area through rotation or reciprocating motion, and then increase its pressure and transport it to the high-pressure area.

Ⅱ. Function of hydraulic valve.

Hydraulic valve is a control element in the hydraulic system, which is used to control the flow direction, pressure and flow of hydraulic oil. There are many types of hydraulic valves, including directional control valves, pressure control valves and flow control valves. Directional control valves are used to control the flow direction of hydraulic oil, such as reversing valves and check valves; pressure control valves are used to control the pressure of hydraulic systems, such as overflow valves and pressure reducing valves; flow control valves are used to adjust the flow of hydraulic oil, such as throttle valves and speed regulating valves.

Ⅲ. Coordinated operation of hydraulic valves and hydraulic pumps.

The coordinated operation between hydraulic valves and hydraulic pumps is mainly shown in the following aspects:

- Pressure matching: The pressure provided by the hydraulic pump has to match the rated pressure of the hydraulic valve. If the pressure provided by the hydraulic pump is too high, it may cause damage to the hydraulic valve; if the pressure is too low, it may not meet the normal working requirements of the hydraulic system. Therefore, when selecting a hydraulic pump and a hydraulic valve, you need to ensure that their pressure ratings match.

- Flow matching: The flow of the hydraulic pump has to match the flow requirements of the hydraulic valve. If the flow of the hydraulic pump is too large, it may cause the hydraulic system to waste energy; if the flow is too small, it may not meet the normal working requirements of the hydraulic system. Therefore, when selecting a hydraulic pump and a hydraulic valve, you need to ensure that their flow levels match.

- Control logic: The control logic between the hydraulic valve and the hydraulic pump needs to be coordinated. For example, when starting the hydraulic system, you need to start the hydraulic pump first to provide sufficient pressure and flow, and then open the corresponding hydraulic valve as needed to control the flow direction, pressure and flow of the hydraulic oil. When shutting down the hydraulic system, you need to close the hydraulic valve first to cut off the flow path of the hydraulic oil, and then shut down the hydraulic pump to stop providing pressure and flow.

IV. Summary.

Hydraulic valves and hydraulic pumps are indispensable components of the hydraulic system, and their coordinated operation is crucial to the normal operation of the entire hydraulic system. In order to ensure the normal operation of the hydraulic system, it is necessary to reasonably select the models and specifications of the hydraulic pumps and hydraulic valves, and operate and maintain them strictly in accordance with the control logic. At the same time, it is also necessary to regularly inspect and maintain the hydraulic system to ensure its long-term stable operation.