Ball Valve vs Butterfly Valve

In modern industrial fluid control systems, valves, as core components for controlling medium flow, their performance directly affects the stability, efficiency, and safety of the entire system.

Ball valves and butterfly valves, as two widely used types of valves, play irreplaceable roles under different working conditions due to their unique structural designs and performance characteristics.

This article will conduct a comprehensive and in-depth comparative analysis of ball valves and butterfly valves from multiple dimensions such as structural principles, material selection, performance parameters, applicable scenarios, installation and maintenance, and development trends, providing detailed references for selection in engineering practice.

I. Ball valve vs butterfly valve: structures and classifications.

The performance differences of valves first stem from their structural designs and working principles. Understanding the basic structures of both is the basis for comprehending their performance characteristics.

If you have learnt the introductions of ball valves and butterfly valves earlier in our blog, you will have a basic knowledge about them. Now we can take a look at the differences between these two types of valves.

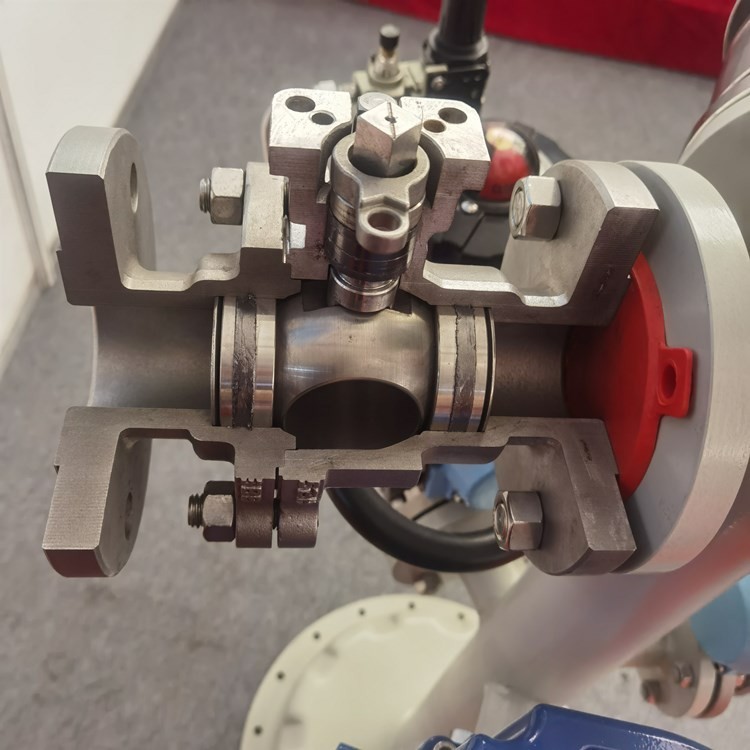

(I) Structures and classifications of ball valves.

A ball valve is a type of valve with a spherical body as the opening and closing element, which is opened or closed by rotating the sphere 90° around the valve stem axis. Its core structure consists of a valve body, a sphere, a valve stem, a valve seat, and a driving device.

The sphere has a through hole. When the through hole coincides with the pipeline axis, the valve is fully open, and the medium can flow freely; when the sphere rotates 90°, the through hole is perpendicular to the pipeline axis, the valve is closed, and the sphere fits tightly with the valve seat to block the flow of the medium.

According to their structural characteristics, ball valves can be classified into the following types:

- Floating ball valves: The sphere has no fixed axis and will displace to a certain extent under the action of medium pressure, making the sphere fit tightly with the outlet end valve seat to achieve sealing. This structure is simple and low in cost, suitable for medium and low-pressure working conditions (generally pressure ≤ PN40), with diameters usually ranging from DN15 to DN300.

- Fixed ball valves: The sphere is fixed by upper and lower shafts, and the position of the sphere remains unchanged during rotation. Sealing is achieved through the movement of the valve seat. It has a stronger pressure-bearing capacity, suitable for high-pressure occasions (up to PN100 and above), with a wider diameter range (DN15 – DN2000).

- Elastic ball valves: The sphere is made of elastic materials or has an elastic groove structure. Under pressure, the sphere can produce slight deformation to enhance the sealing effect with the valve seat, suitable for occasions with extremely high requirements for sealing performance, such as flammable and explosive medium delivery systems.

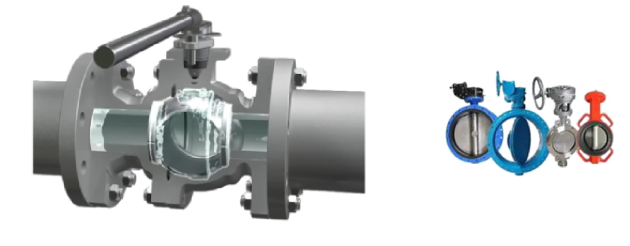

(II) Structures and classifications of of butterfly valves.

A butterfly valve uses a disc-shaped butterfly plate as the opening and closing element, which controls the flow of the medium by rotating the butterfly plate around the valve stem axis (0° – 90°). Its basic structure includes a valve body, a butterfly plate, a valve stem, a valve seat, and a driving device. When the butterfly plate rotates to be parallel to the pipeline axis, the valve is fully open; when it rotates to a vertical state, the valve is closed, and the edge of the butterfly plate contacts the valve seat to form a seal.

Butterfly valves can be classified in many ways, commonly as follows:

- By sealing form: Divided into soft-sealed butterfly valves and hard-sealed butterfly valves. The valve seat of soft-sealed butterfly valves is made of elastic materials such as rubber and polytetrafluoroethylene, with good sealing performance but limited temperature and pressure resistance; the sealing surfaces of the valve seat and butterfly plate of hard-sealed butterfly valves are made of metal materials (such as stainless steel, cemented carbide), with strong temperature and pressure resistance, but the sealing performance is slightly lower than that of soft-sealed ones.

- By structural form: Including center-sealed butterfly valves, single-eccentric butterfly valves, double-eccentric butterfly valves, and triple-eccentric butterfly valves. The single-eccentric design reduces the friction between the butterfly plate and the valve seat; the double-eccentric design further improves the sealing performance and service life; the triple-eccentric butterfly valve achieves zero-leakage sealing through a unique eccentric angle design, suitable for high-pressure working conditions.

- By driving mode: Can be divided into manual butterfly valves, pneumatic butterfly valves, electric butterfly valves, and hydraulic butterfly valves. Different driving modes adapt to different automatic control needs.

II. Ball valve vs butterfly valve: impact of material selection on the performance.

The material selection of valves is directly related to their corrosion resistance, high-temperature resistance, wear resistance, and sealing performance, and is a key factor determining the applicable working conditions of valves.

(I) Material selection for ball valves.

- Valve body materials:

- Cast iron: Low cost, suitable for low-pressure, normal-temperature, non-corrosive media (such as tap water), but with poor strength and corrosion resistance.

- Cast steel: Including carbon steel, alloy steel, etc., with high strength and good temperature and pressure resistance, suitable for medium and high-pressure steam, oil products, and other media.

- Stainless steel: Such as 304 and 316 stainless steel, with excellent corrosion resistance, suitable for corrosive media such as acids, alkalis, and seawater.

- Special alloys: Such as Hastelloy and Monel alloy, used for strongly corrosive media (such as concentrated nitric acid, hydrofluoric acid), but with high cost.

- Sphere and valve seat materials:

- The sphere material is usually the same as the valve body or uses a higher-strength alloy. For example, the surface of a stainless steel sphere can be hardened (chrome-plated, nitrided) to enhance wear resistance.

- The valve seat material is selected according to the sealing requirements: Soft-sealed valve seats commonly use polytetrafluoroethylene (PTFE) and reinforced polytetrafluoroethylene (RPTFE), suitable for low-temperature, less corrosive media; metal-sealed valve seats use stainless steel and cemented carbide, suitable for high-temperature, high-pressure, and particle-containing media.

(II) Material selection for butterfly valves.

- Valve body materials:

- Gray cast iron: Used in low-pressure water supply and drainage systems, with low cost.

- Ductile iron: With better strength and toughness than gray cast iron, suitable for medium and low-pressure, large-diameter pipelines (such as DN300 and above).

- Cast steel and stainless steel: Same as ball valves, suitable for medium and high-pressure, corrosive medium scenarios respectively.

- Butterfly plate and valve seat materials:

- The butterfly plate material is mostly cast iron, cast steel, or stainless steel, and the surface can be treated with anti-corrosion (such as plastic coating, rubber lining) to adapt to corrosive media.

- Soft-sealed valve seats commonly use nitrile rubber (NBR), ethylene propylene diene monomer (EPDM), fluororubber (FKM), etc.: Nitrile rubber has good oil resistance; EPDM has excellent temperature resistance and aging resistance, suitable for hot water and steam; FKM has strong corrosion resistance and temperature resistance, suitable for high-temperature and strong corrosive environments.

- Hard-sealed valve seats use stainless steel, cobalt-based alloys, etc., and are matched with metal butterfly plates, suitable for high-temperature, high-pressure, and particle-containing media.

- Material matching: The materials of the butterfly plate and valve seat of the butterfly valve need to consider the friction coefficient and wear resistance. For example, although metal-to-metal sealing is resistant to high temperature and pressure, sufficient surface precision is required to reduce leakage; when a rubber valve seat is matched with a metal butterfly plate, it is necessary to avoid excessive surface roughness of the butterfly plate leading to rubber wear.

III. Comparison of Core Performance Parameters.

The core performance parameters of valves are key indicators to measure their applicability, including sealing performance, flow characteristics, pressure and temperature range, flow capacity, etc. The following is a detailed comparison between ball valves and butterfly valves from these dimensions.

(I) Sealing performance.

Sealing performance is one of the most important performances of valves, directly related to whether the medium leaks and the system efficiency.

- Ball valves: Adopt a line or surface sealing structure between the sphere and the valve seat, with close contact of the sealing pair and extremely low leakage rate. The leakage rate of soft-sealed ball valves can reach below 10⁻⁶ mL/s, and metal-sealed ball valves can also achieve good sealing under high pressure, suitable for the transportation of flammable, explosive, toxic, and harmful media, such as natural gas pipelines and chemical raw material transmission systems.

- Butterfly valves: The leakage rate of soft-sealed butterfly valves can reach about 10⁻⁴ mL/s, which can meet the needs of general working conditions; the triple-eccentric hard-sealed butterfly valve, through structural optimization, can have a leakage rate close to that of ball valves, but overall, the sealing performance of butterfly valves is slightly inferior to that of ball valves, especially in high-pressure and high-viscosity media, it is easy to cause the sealing surface to fit loosely due to pressure deformation.

(II) Flow characteristics and flow resistance.

Flow characteristics reflect the ability of a valve to control the medium flow, and flow resistance affects the energy consumption of the system.

- Ball valves: When fully open, the through hole of the sphere is basically consistent with the inner diameter of the pipeline, the medium flows smoothly, and the flow resistance coefficient is extremely small (generally between 0.1 and 0.5), almost no additional pressure loss is generated, suitable for scenarios requiring large flow and low energy consumption, such as water conservancy projects and crude oil transportation pipelines.

However, the flow regulation characteristics of ball valves are poor. In the opening range of 5% – 90%, the flow changes sharply, making it difficult to achieve precise flow control.

- Butterfly valves: When fully open, the butterfly plate still occupies part of the pipeline space, and the flow resistance coefficient is larger than that of ball valves (generally between 0.5 and 2.5), but the flow regulation characteristics are excellent.

Its flow has an approximately linear relationship with the butterfly plate opening, and precise regulation can be achieved in the opening range of 10% – 80%, which is often used in systems that require continuous flow regulation, such as water volume regulation in heating systems and air volume control in ventilation pipelines.

(III) Applicable pressure and temperature range.

- Ball valves: The applicable pressure range is extremely wide, from vacuum (negative pressure) to ultra-high pressure (PN420 and above). For example, floating ball valves are suitable for PN16 – PN40, fixed ball valves can reach PN100 – PN250, and specially designed ball valves can even withstand higher pressures.

The applicable temperature range is also large. Soft-sealed ball valves can reach -20℃ – 150℃, and metal-sealed ball valves can work stably in the range of -29℃ – 540℃, suitable for high-temperature steam, high-temperature oil products, and other media.

- Butterfly valves: Soft-sealed butterfly valves are limited by the sealing material, with applicable pressure generally ≤ PN16 and temperature ≤ 150℃; the pressure range of hard-sealed butterfly valves can be extended to PN40 – PN64, and triple-eccentric hard-sealed butterfly valves can even reach PN100, with a temperature range of -40℃ – 425℃.

But overall, butterfly valves are more suitable for medium and low-pressure, medium and low-temperature working conditions, such as urban water supply and drainage (PN10 – PN16) and air conditioning systems (temperature 0℃ – 120℃).

(IV) Medium adaptability.

- Ball valves: Have extremely strong adaptability to media, and can handle water, oil, gas, steam, corrosive liquids, high-viscosity media (such as asphalt, syrup), and particle-containing media (such as mud, ore pulp). Due to the sphere structure not easily retaining media and the sealing surface not easily being scratched by particles (metal sealing), they perform well in impurity-containing media, such as mineral pulp transportation in the mining industry and sludge discharge in sewage treatment.

- Butterfly valves: Have certain requirements for the cleanliness of the medium. If soft-sealed butterfly valves transport media containing large particles or fibers, they are prone to cause wear or blockage of the sealing surface; although hard-sealed butterfly valves can withstand certain particles, long-term use will still affect the sealing performance.

Therefore, butterfly valves are more suitable for clean media or those containing a small amount of fine particles, such as tap water, air, and steam.

(V) Size and weight.

Under the same diameter, the size and weight of ball valves and butterfly valves differ significantly:

- Ball valves: With a complex structure, the valve body needs to accommodate the sphere and sealing mechanism, so they are large in volume and heavy in weight.

For example, the weight of a DN300 cast steel ball valve can reach 200 – 300kg, and the weight of a DN600 ball valve can exceed 1000kg. The transportation, installation, and maintenance of large-diameter ball valves require special equipment, increasing engineering costs.

- Butterfly valves: With a compact structure, the valve body is flat, and the design of the butterfly plate and valve stem makes their weight much smaller than that of ball valves with the same diameter. The weight of a DN300 butterfly valve is usually 50 – 100kg, and the weight of a DN600 butterfly valve is about 200 – 300kg. The lightweight advantage of large-diameter butterfly valves (such as DN1000 and above) is more obvious, which can significantly reduce the load-bearing requirements of pipeline supports and installation difficulty.

IV. Comparison of applicable scenarios and selection cases.

(I) Industrial pipeline systems.

- Petrochemical industry:

- Ball valves: Widely used in the transportation pipelines of crude oil, refined oil, liquefied petroleum gas (LPG), and chemical raw materials, especially in high-pressure and corrosive medium scenarios. For example, in propylene transportation pipelines, 316 stainless steel ball valves are selected, which can withstand the corrosiveness and high pressure (PN25) of the medium, and have reliable sealing to avoid safety accidents caused by leakage.

- Butterfly valves: Mostly used in circulating water systems, low-pressure steam pipelines, and sewage treatment links. For example, in the cooling circulating water pipeline (DN800, PN10) of a chemical plant, soft-sealed butterfly valves are used, which can meet the flow regulation requirements and reduce costs.

- Power industry:

- Ball valves: In high-pressure water supply pipelines and steam extraction pipelines of steam turbines in thermal power plants, alloy steel fixed ball valves are selected, which can withstand high temperature and high pressure (300℃, PN160) to ensure the stable transportation of steam and feed water.

- Butterfly valves: Used in boiler induced draft and supply air pipelines, as well as cooling water systems. For example, in the return water pipeline of cooling towers (DN1200, PN6), electric butterfly valves are used to realize automatic air volume regulation and improve boiler efficiency.

(II) Municipal engineering.

- Water supply and drainage systems:

- Ball valves: Suitable for small-diameter pipelines such as community water supply branch pipes and fire pipelines (DN50 – DN200), especially in occasions requiring frequent opening and closing, such as fire hydrant control valves. The quick opening and closing characteristics of ball valves can ensure the response speed in emergency situations.

- Butterfly valves: Dominate in urban main water supply pipelines and inlet and outlet pipelines of sewage treatment plants (DN600 – DN2000). Their large-diameter and lightweight characteristics reduce installation costs, and their regulation performance is suitable for controlling the water level and flow of sewage treatment pools.

- Heating and air conditioning systems:

- Ball valves: Used in household heating inlet valves to realize single-household control. Due to their good sealing performance, they can avoid energy waste caused by heating leakage.

- Butterfly valves: In the water systems of central air conditioning chillers and fan coils, they are used as flow regulating valves. The opening of the butterfly plate is controlled by electric actuators to accurately regulate room temperature, such as in the air conditioning systems of shopping malls and office buildings.

(III) Applications in special working conditions.

- Particle-containing media: Such as mineral pulp pipelines in the mining industry and mud pipelines in dredging projects, ball valves are preferred. Their straight-through structure is not easy to block, and the metal sealing surface is wear-resistant, ensuring long-term stable operation.

- High-temperature and high-pressure steam: In the main steam pipelines (450℃, PN100) of thermal power plants, metal-sealed fixed ball valves are selected, while butterfly valves are generally not applicable because their sealing surfaces are prone to aging at high temperatures.

- Food and pharmaceutical industry: For clean media such as pure water and liquid medicines, sanitary ball valves (mirror-polished, dead-angle-free structure) are selected to avoid medium residue and pollution; butterfly valves need to adopt food-grade rubber seals for feeding regulation of liquid medicine mixing tanks.