Operation Principle, Types and Applications of Manual Flanged Ball Valves.

Manual flanged ball valves are a common type of valve. The following contents described in four aspects may help us have a full understand of manual flanged ball valves.

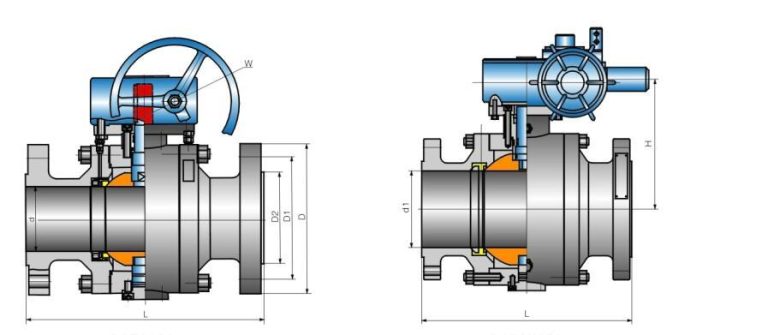

1.Structure characteristics.

- The ball: the ball is the core part, and there is a circular hole on the ball. When the ball rotates, the communication state between the hole and the pipe changes, so as to realize the function of opening or closing the valve in order to open or stop the fluid in the pipe.

- Seat: the seat has good sealing performance and is usually made of soft materials (such as rubber, etc.) or metal materials. The soft valve seat has good sealing effect and is suitable for medium and low pressure working conditions; while the metal valve seat is resistant to high temperature and wear, and can be used for high pressure and special working conditions.

- Flange connection: the valve is connected to the pipeline by the flange. The connection by flange is firm, easy to install and disassemble, and can meet the requirements of pipeline connection with different pipe diameters.

2.Operation principle.

Its main feature is manual operation. The valve stem is manually rotated by the handwheel, and the stem drives the ball to rotate. When the handwheel is rotated clockwise, the ball gradually closes the channel and prevents the fluid from passing through; counterclockwise rotation opens the channel and allows the fluid to flow smoothly.

3.Manual flanged ball valves can be classified in different ways:

By structure

Floating ball valve: The ball will be tightly pressed against the sealing surface of the outlet under the pressure of the medium to ensure the sealing of the outlet, which is suitable for low to medium pressure pipeline systems.

Fixed ball valve: The ball is fixed and does not move after being pressurized. It usually has a floating seat and can rotate freely along the axis perpendicular to the valve channel. It has small torque, small valve seat deformation, stable sealing performance and long service life. It is suitable for high pressure and large diameter occasions.

Elastic ball valve: The ball is elastic and the elastic deformation of the ball is generated by external force to ensure sealing. It is suitable for high temperature and high pressure media.

V-type ball valve: The ball has a V-shaped structure and has a shearing effect. It is particularly suitable for media containing fibers or tiny solid particles, such as papermaking, chemical industry, metallurgy and other industries, and can also achieve more precise flow regulation.

Orbital ball valve: The operation equipment is a ball, which rotates around the center line of the valve body to achieve opening and closing.

By sealing material

Soft sealing ball valve: The sealing material is soft materials such as rubber or polytetrafluoroethylene, which is suitable for fluid pipelines with high sealing requirements.

Hard sealing ball valve: The sealing material is metal material, which is suitable for fluid pipelines in harsh environments such as high temperature and high pressure.

By the medium used

Water ball valve: suitable for water medium pipelines such as tap water, cooling water, hot water, etc.

Steam ball valve: suitable for high temperature medium pipelines such as steam and hot air.

Gas ball valve: suitable for gas medium pipelines such as oxygen, nitrogen, hydrogen, etc.

Acid and alkali ball valve: suitable for corrosive medium pipelines such as strong acid and strong alkali.

By material

Metal valves: such as carbon steel valves, alloy steel valves, stainless steel valves, cast iron valves, titanium alloy valves, etc.

Metal body lined valves: such as rubber lined valves, fluorine lined valves, lead lined valves, plastic lined valves, enamel lined valves.

Non-metal valves: such as ceramic valves, glass valves, plastic valves.

4.What are the fields of applications of manual flanged ball valves?

Manual flanged ball valves are widely used in industrial fields such as petrochemicals, natural gas transportation, water supply and drainage systems. In the petrochemical industry, it can be used to control the flow of various oil products and chemical raw materials in the pipelines ; in the water supply and drainage system, it can be used to regulate and cut off the water flow.