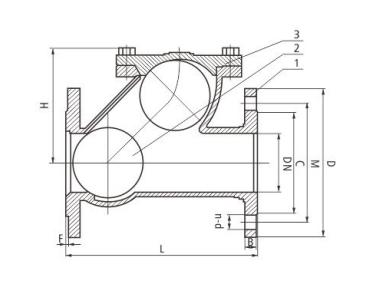

Female Thread 304 Stainless Steel Check Valve

Stainless steel check valve is mainly made of stainless steel, used to prevent backflow. It has high corrosion resistance and strength, and is suitable for various industrial environments. This kind of valve usually has a compact shape and adopts a built-in spring structure, and can be installed vertically or horizontally in the pipeline system to effectively prevent the reverse flow of pipeline media.

The female thread check valve employs a threaded connection mode, and realizes sealing and fixation through the cooperation of female and male threads. Specifically, the female threads and male threads are directly tightened, using polytetrafluoroethylene raw tape for sealing. This material has good corrosion resistance, excellent sealing effect, and is convenient to use and store.

Main features of the female thread stainless steel check valve.

Material: 304 stainless steel (SUS304), featuring good corrosion resistance and strength.

Connection method: Female thread connection, suitable for various pipeline systems.

Applicable media: Suitable for water, oil, and various liquid media. The working temperature can reach up to 420°C for gas media and 170°C for liquid media.

Installation method: Can be installed either vertically or horizontally.

Description

| Material | Stainless steel 304 |

| Nominal Size | 1/2″-4″ |

| Work Temperature | Normal |

| Color | Stainless steel |

| Use | Water ,Oil ,Gas plumbing system |

| Pressure | PN16 |

The data is for reference only, please consult sales@wayvalve.com for details.

The applications of the female thread stainless steel check valve.

The 304 stainless steel check valve with internal threads is widely used in pipeline systems for water, oil, and liquid media, such as the chemical, petroleum, and pharmaceutical industries where backflow prevention is required, .

What are the differences between the female and male thread stainless steel check valve?

The main differences between female thread and male thread stainless steel check valves are their thread positions and connection methods:

Thread Position:

Female thread: Threads are inside the valve body, connecting with male-threaded pipes.

Male thread: Threads are outside the valve body, connecting with female-threaded pipes.

Application Scenarios:

Female thread: Suitable for low-to-medium pressure systems (e.g., domestic water pipes, small equipment) due to compact design.

Male thread: Better for medium-to-high pressure systems (e.g., industrial pipelines, high-pressure equipment) with stronger structural stability.

Sealing and Installation:

Female thread: Relies on thread sealant (e.g., PTFE tape) for sealing, ideal for space-constricted areas.

Male thread: Often uses metal gaskets for high-pressure sealing, easier to install in exposed or vibration-prone environments.

INQUIRY

![[rank_math_breadcrumb]](https://wayvalve.com/wp-content/uploads/2025/03/non-slam-check-valve-768x934.jpg)