Knife Gate Valve: A Key Component for Industrial Pipeline Control

Knife gate valve, also known as a knife-type gate valve, slurry valve, or mud valve, is a type of valve that uses a gate as its opening/closing component. Its core design feature lies in the blade-shaped gate, which can vertically cut through the medium, making it particularly suitable for handling fibrous, granular, or high-viscosity fluids. The valve body has no traditional chamber structure; the gate rises and falls through side guide grooves, and the bottom lug presses against the valve seat to achieve sealing. Some models can be equipped with O-ring seals for bidirectional sealing.

As a common control device in industrial pipelines, the knife gate valve has become an important part of industrial pipeline systems due to its unique structural characteristics, reliable performance, and wide application range. This article will provide an in-depth understanding of the knife gate valve and explore its key role in industrial pipeline control.

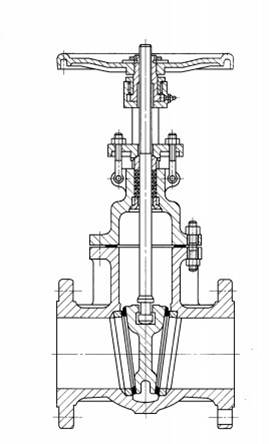

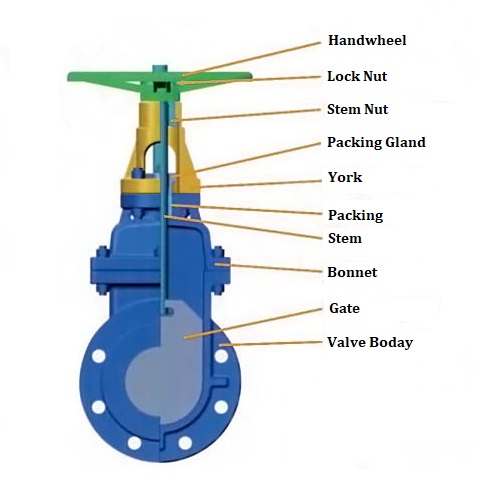

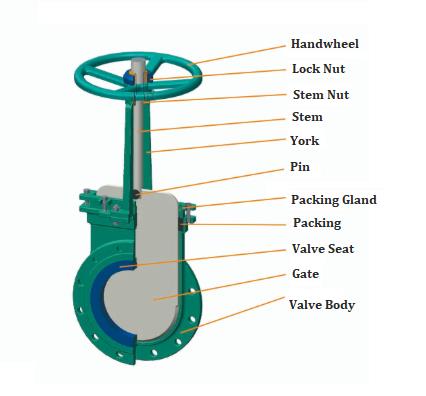

Structure of the knife gate valve.

1. Main components of knife gate valve.

The knife gate valve is primarily composed of the valve body, gate, stem, and seals.

- Valve Body: Usually made by casting or forging processes, it has high strength and sealing performance. The valve body comes in various shapes, such as straight-through and angle types, to meet different installation requirements.

- Gate: The gate is a key component of the knife gate valve, named for its blade-like shape. It is typically made of corrosion-resistant materials like stainless steel, featuring good wear resistance and sealing performance. When closed, the gate fits tightly against the valve body’s sealing surface to intercept the medium.

- Stem: The stem connects the gate to the operating mechanism, transmitting the operating force to enable the gate to open and close. It is usually made of high-strength materials with excellent corrosion and wear resistance.

- Seals: Seals in the knife gate valve mainly include the seal between the valve body and gate, and the seal between the stem and valve body. The quality of seals directly affects the valve’s sealing performance, and materials like rubber or PTFE (polytetrafluoroethylene) are commonly used.

2. Types devided by structure.

- Valve with cover and valve without cover

In knife gate valves without a cover, the gate is exposed outside the valve body when opened. Prolonged opening can cause dust, impurities, etc., in the environment to adhere to the gate surface, leading to difficulties in closing the gate and leakage at the gate packing. Thus, knife gate valves with a cover were developed. - Rising stem (outside screw and yoke, OS&Y) and non-rising stem (inside screw, IS)

- Knife gate valves also come in two forms: rising stem and non-rising stem.

- Rising stem: The stem lifts together with the gate to complete the opening/closing process.

- Non-rising stem: The nut is fixed on the gate, and the stem rotates to drive the gate to rise/fall. This type is suitable for installations with limited height space.

- Knife gate valves also come in two forms: rising stem and non-rising stem.

- Split-body and integral-body knife gate valves.

- The valve body of a knife gate valve can be split or integral.

- Split-body: The valve body is divided into two parts, which are fixed together with bolts after processing, facilitating machining and maintenance.

- Integral-body: It has high strength and a lower risk of external leakage.

- The valve body of a knife gate valve can be split or integral.

How does a knife gate valve work?

The knife gate valve operates by driving the stem and gate through an operating mechanism to achieve opening and closing:

- Open: When the operating mechanism moves the stem upward, the gate rises, opening the valve for the medium to flow through smoothly.

- Closed: When the operating mechanism moves the stem downward, the gate gradually descends and fits tightly against the valve body’s sealing surface to intercept the medium.

Applicable media for knife gate valves.

Knife gate valves are applicalbe for a various scopes of media, such as gold ore powder, tailings, mineral sand, slag, coal slime, sand, steel ash, paper pulp, wood pulp, cement slurry, fibers, dust, powders, grains, chemicals, treated sewage, municipal wastewater, settled oil, asphalt, silo outlets, fruits, grains, beer, beverages, oils, steam, gas transportation, as well as water supply, drainage, and slag discharge in power plants.

Benefits and drawbacks of different sealing forms.

- Soft Sealing (Unidirectional or Bidirectional), Temperature ≤280°C: Suitable for gases, liquids, and other highly fluid media with low density.

- Benefits: Strong sealing performance, less prone to internal/external leakage.

- Drawbacks: Seals may be damaged by contact with particles or high-temperature media.

- Hard Sealing (Unidirectional or Bidirectional), Temperature ≤1000°C: Suitable for various solid, dust, and granular media.

- Benefits: High wear resistance.

- Drawbacks: Poor sealing performance, not suitable for gas or liquid media pipelines.

Selection of driving methods.

Knife gate valves can be driven by manual, pneumatic, electric, hydraulic, or chain drive:

- For a nominal diameter DN ≥ 400 mm or high nominal pressure, bevel gear drive is recommended to reduce the operating torque on the handwheel.

- For pneumatic drive, consider accessories such as solenoid valves, filter regulators, and travel switches, and whether explosion-proof performance is required.

- For electric drive, consider the voltage of the electric actuator, control mode, and explosion-proof requirements.

- For hydraulic drive, consider whether it is an electro-hydraulic integrated type; a single hydraulic cylinder requires a supporting hydraulic station.

- For manual operation in high-altitude or inconvenient positions, consider using chain drive for switching.

Advantages and disadvantages of knife gate valves

- Advantages:

- Hard-sealed knife gate valves are the preferred choice for slurry, mud, and paper pulp pipelines.

- Simple structure, small size, light weight, and easy installation.

- Disadvantages:

Only suitable for low-pressure pipelines. Gate valves are a large category with many models, structures, and applicable working conditions, while knife gate valves are mainly used in slurry pipelines, also known as slurry pipeline special valves.

As a key component of industrial pipeline control, the importance of the knife gate valve cannot be ignored. With the continuous development of industrial production technology, the knife gate valve will continue to optimize in structure, materials, and performance, providing strong support for the efficient and safe operation of industrial pipeline systems. Understanding and mastering the relevant knowledge of knife gate valves is of great significance for improving the level of industrial pipeline control.