Industrial Valve Manufacturer

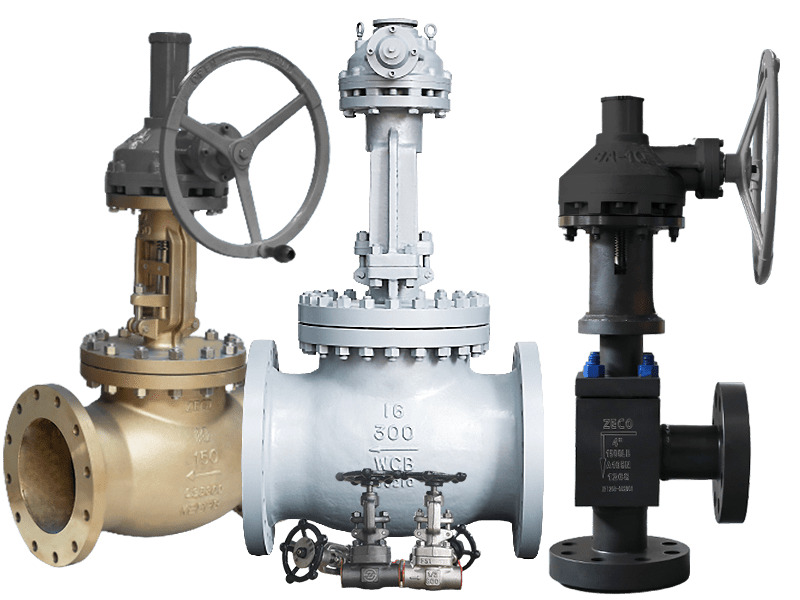

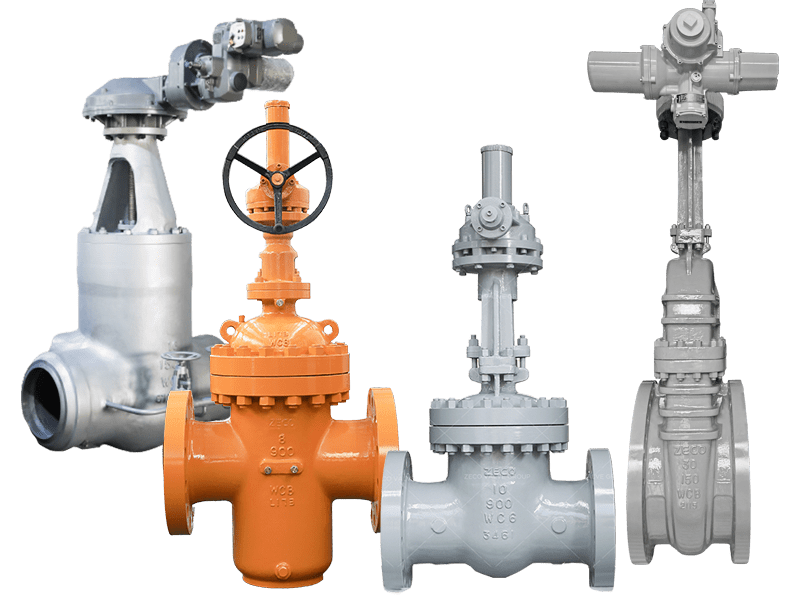

We take pride in supplying our clients with world-class and high-quality standard and custom-made industrial valves.

Humble, United, Diligent, Progressive, With Integrity – Delivering for Our Clients

As an industrial valve manufacturer, Top Wells aims to exceed customer expectations with value-added services and products

Superior Valve Services Since 1991

Top Wells Company limited, is the leading industrial valve manufacturer based in Shaoguan, China since 1991. . With deep roots in the Oil, Gas, and Water Treatment Industries, Top Wells embodies quality, expertise, and trust. Join us in elevating your projects with unparalleled excellence and reliability.

KNOW MORE?

Send a message to sales@wayvalve.com

Reliable Valves for Oil & Gas, Cryogenic, Offshore, and Chemical Industries

Valve applications in industrial processes regulate fluid or gas flow and pressure for efficient operations.

Valves facilitate the proper flow and pressure of fluids to optimize the performance of oil and gas systems.

Valves regulate flow and pressure to optimize power plant efficiency, ensuring safe and reliable operations.

Valves ensure optimal fluid flow and pressure in LNG processing, storage, and transportation operations.

Valve applications in refining and petrochemical industries encompass fluid control, process optimization, and safety assurance.

LEAVE A MESSAGE