Differences Between Swing Check Valve and Lift Check Valve

The check valve is used when the medium is required to flows only in one direction. It can prevent backflow. In terms of structure, the check valve can be classified into three types: lift check valve, swing check valve and butterfly check valve. Topwells here will introduce the differences between the lift check valve and the swing check valve in the aspects of structure, working principle and application.

Structural difference of Swing Check Valve and Lift Check Valve.

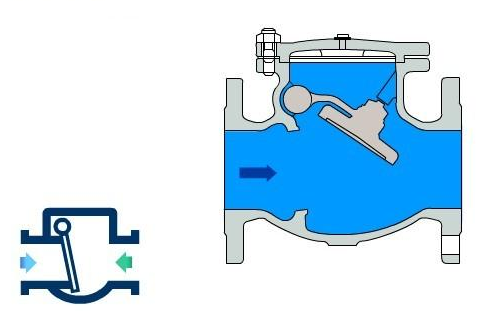

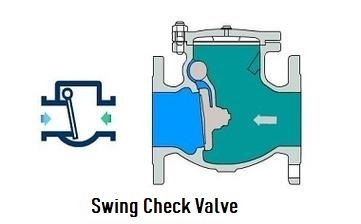

A swing check valve controls the opening and closing of the fluid by rotating the valve disc. The valve disc is usually spherical or cylindrical and opens or closes the valve through rotation.

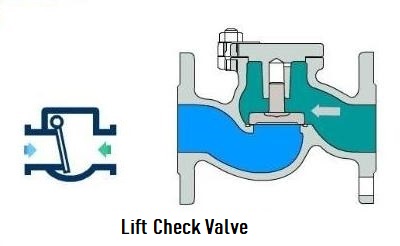

A lift check valve controls the opening and closing of the fluid by moving up and down. The valve usually operates in an up-and-down manner.

Differences of Swing Check Valve and Lift Check Valve.

The swing check valve achieves the check function by rotating the valve disc. When the fluid flow direction is reversed, the valve disc will be impacted by the fluid, causing it to close the valve and prevent the backflow of the fluid.

The lift check valve achieves the check function through the upward and downward movement of the valve seat. When the fluid flow direction is reversed, the valve seat will be impacted by the fluid, causing it to close the valve and prevent the backflow of the fluid.

Differences of Swing Check Valve and Lift Check Valve.

Swing check valves are suitable for environments with smaller flow rates and lower pressures, and are commonly found in home and small pipeline systems.

Lift check valves are suitable for environments with larger flow rates and higher pressures, and are commonly found in industrial and large pipeline systems.

In general, swing check valve and lift check valve have the differnce in strucuture, working method and application scopes. Which type to Choose should be determined based on specific requirements and the operating environment.

![[rank_math_breadcrumb]](https://wayvalve.com/wp-content/uploads/2025/03/non-slam-check-valve-768x934.jpg)