Why Does the Ball of a Ball Valve Have a Balance Hole?

A ball valve is a common fluid control valve that is widely used in the industrial field. The ball valve with a balance hole is a special design, which has some unique characteristics and application scenarios. This post will provide a comprehensive and detailed introduction to the ball valve with a balance hole.

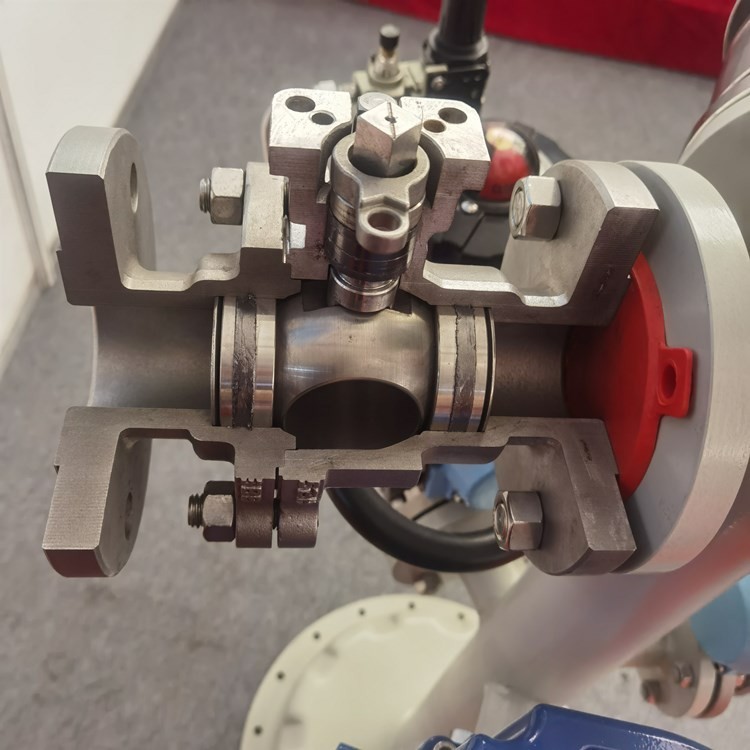

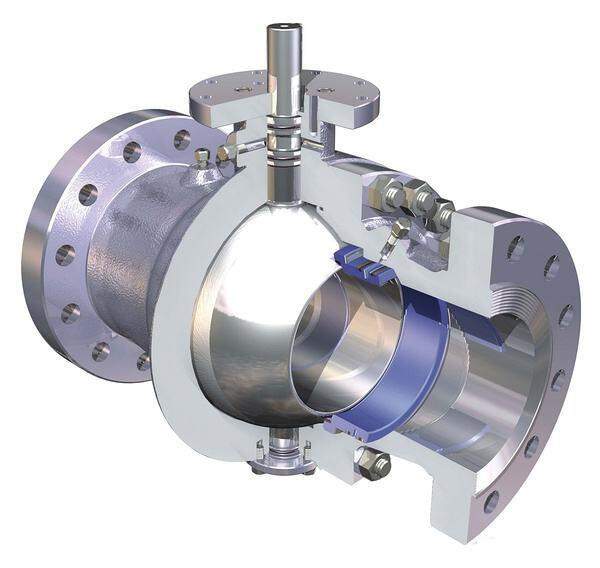

Structure of the ball valve with a balance hole.

Compared with a common ball valve, the most significant difference of the ball valve with a balance hole is its special internal structure design. Usually, a small hole is set on the ball of the ball valve. This small hole is connected to the pressure in the pipeline and is connected to the outlet side of the ball valve through the pipeline. The purpose of this design is to reduce the pressure difference between the two sides of the ball when the ball valve is closed, and prevent the situation where it is difficult to close the ball valve due to excessive medium pressure.

Working principle of the ball valve with a balance hole.

When the ball valve with a balance hole is in operation, when the valve needs to be closed, the pressure of the medium will act on both sides of the ball through the balance hole, playing a balancing role and reducing the pressure difference between the two sides of the ball. In this way, even if the medium pressure is very high, it will not cause excessive resistance to the operation of the ball valve. At the same time, when the valve is opened, the balance hole can help reduce the impact force generated when the medium passes through the valve, thus prolonging the service life of the ball valve.

Advantages of the ball Valve with a balance hole.

The ball valve with a balance hole has the following advantages compared with a common ball valve:

- It prevents the ball valve from being difficult to close due to excessive medium pressure;

- It reduces the impact force when the medium passes through the valve, prolonging the service life of the ball valve;

- It improves the safety and reliability of the ball valve during use.

Application scenarios of ball valve with a balance hole.

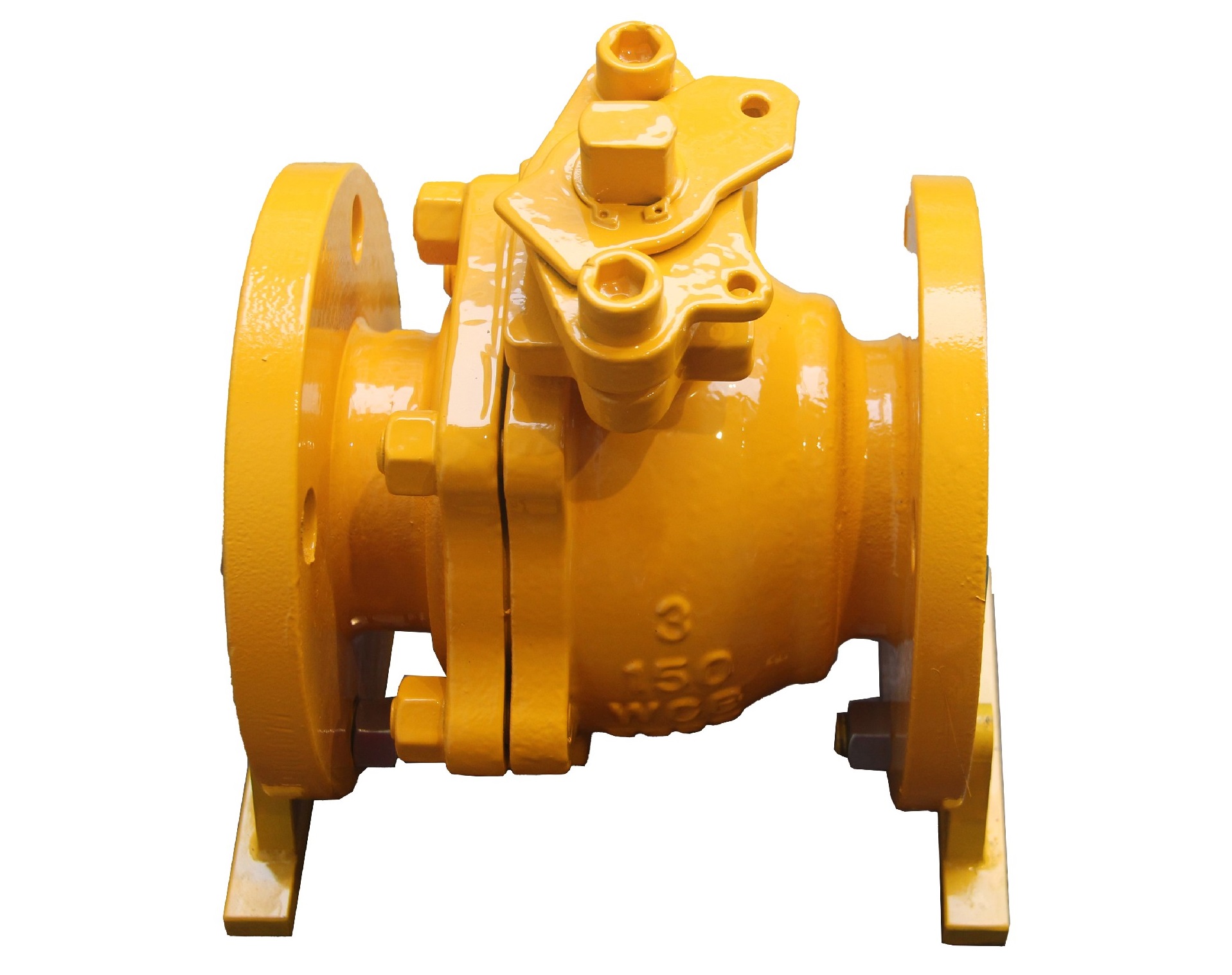

The ball valve with a balance hole is suitable for situations where the medium pressure is relatively high, especially when the medium contains solid particles or is corrosive. For example, in industries such as chemical engineering, petroleum, and metallurgy, the ball valve with a balance hole has been widely used. In addition, due to its flexible operation and simple structure, it is also suitable for general fluid control systems.

Selection and precautions of the ball valve with a balance hole.

When selecting a ball valve with a balance hole, it is necessary to comprehensively consider factors such as the characteristics of the medium, working pressure, and temperature. In addition, during installation and maintenance, it is necessary to pay attention to regularly cleaning the balance hole to ensure its unobstructedness. Moreover, it is also necessary to reasonably select the valve body material and sealing material according to the actual working conditions to ensure the stable operation of the ball valve.

As a fluid control valve with a special design, the ball valve with a balance hole plays an important role under specific working conditions.