Ball Valve Working Principle and Components

How does a ball valve work?

A ball valve is a shut-off device that regulates the flow of a liquid or gas using a rotating ball with a hole. By turning the ball a quarter turn (90 degrees) around its axis, the valve either opens or closes, allowing the medium to pass through or blocking it. Ball valves are known for their long lifespan and provide dependable sealing throughout their use, even when left unused for extended periods. They are more resistant to contaminated media than most other valve types.

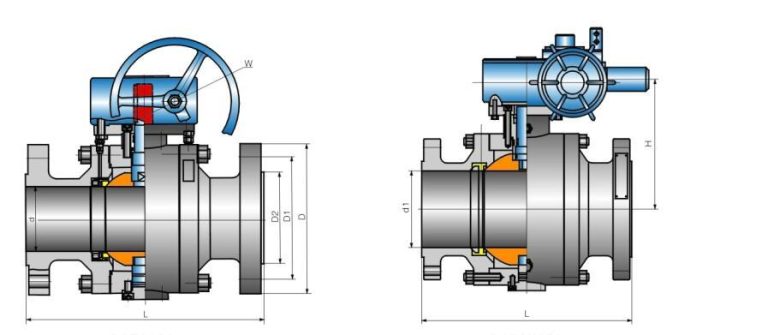

Certain types of ball valves are also employed as control valves. This use is less frequent due to the relatively limited precision in controlling flow rates compared to other control valve types. However, ball valves have some advantages in this regard. For instance, they maintain reliable sealing even when the media is dirty. Figure 1 illustrates a cross-section of a ball valve.

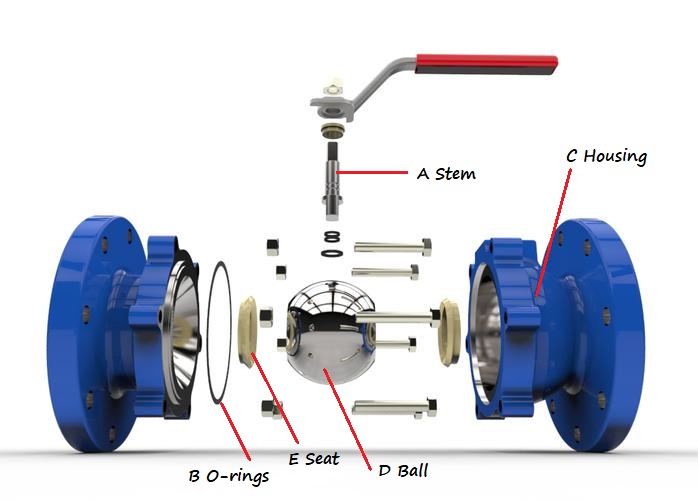

The diagram of five main components of a ball valve.

It is important to know the five main ball valve parts to understand the working principle of a ball valve.

- (A) Valve stem: The valve stem connects the actuator (e.g., handle or actuator (electric or pneumatic)) to the ball.

- (B) O-rings: O-rings on the valve’s seat help prevent leakage.

- (C) Housing: The housing supports all the valve’s inside components and protects them from application and environmental conditions.

- (D) Ball: The ball has a hollow bore through which fluid can flow when the valve is opened.

- (E) Seat: The seat supports and seals the ball component.

When the valve stem is turned a quarter-turn the bore is either open to the flow allowing media to flow through or closed to prevent media flow. A ball valve’s circuit function, housing assembly, ball design, and operation types all impact its operation.