An Overview of V Ball Valve

I. What is a V ball valve?

The V-ball valve is a specially designed valve belonging to the fixed ball valve family, named for its unique V-port ball and seat design.

The V ball valve integrates advantages such as simple structure, tight sealing, wide adjustment range, and long service life. It demonstrates excellent performance under both large and small flow coefficients, making it suitable for scenarios with high requirements for throttling and control. It is widely applied in fields such as pipeline transportation, water conservancy and hydropower, pharmaceuticals, and nuclear power.

This ariticle will introduce the V ball valves mainly from the aspects of principle, characteristics, common faults and solutions.

II. Main characteristics of the V ball valves.

1. Structural features.

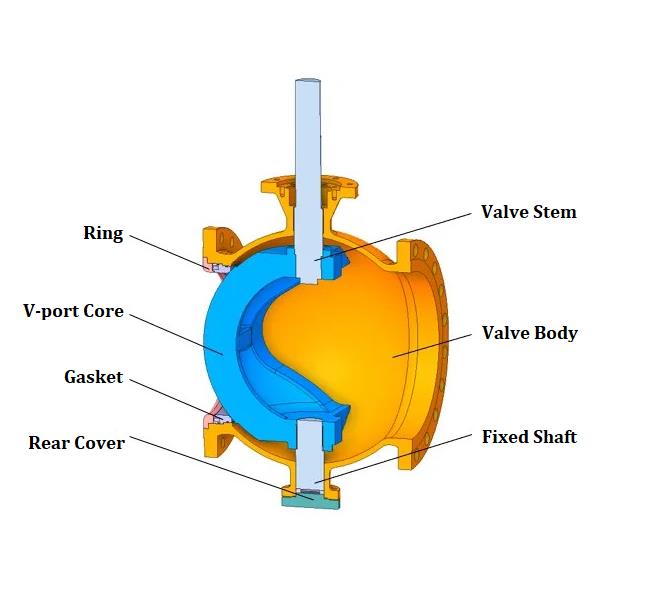

V ball valves are composed of the valve body, valve core (V-port ball), valve stem, seals, etc.

- Valve body: typically made by casting or forging, ensuring high strength and sealing performance.

- Valve core: the key component with a V-shaped notch, usually made of stainless steel or alloy steel for high wear and corrosion resistance.

- Single seat design: features only one sealing point, enhancing sealing performance and reducing leakage risks.

2. Flow characteristics.

- Equal percentage flow: the flow changes proportionally with the valve opening, making it ideal for applications requiring precise flow control.

- Wide adjustment range: the turn-down ratio reaches 100:1, allowing continuous flow adjustment from fully open to nearly closed.

3. Applicalbe media.

The V-shaped notch generates a shearing effect, making it suitable for media containing fibers, tiny solid particles, or slurries that easily clog traditional valves.

4. Other Advantages.

- Maintains good sealing under high pressure differences and large diameters.

- Ensures high control accuracy in high-viscosity media and low Reynolds number conditions.

III. Operating principle of V-port ball valve.

The V-port ball valve controls flow by rotating the valve core:

- Opening process: rotate the handle or actuator (e.g., electric/pneumatic actuator) to drive the ball, gradually increasing the flow area of the V-shaped notch and allowing fluid passage.

- Closing process: the V-shaped notch of the core tightly fits the seat, forming a seal to block fluid flow.

IV. Two common types of acuated V-ball valve.

1. Pneumatic V ball valve.

Overview.

The pneumatic v type ball valve compressed air as its power source. It drives the rotation of the V-port ball via a pneumatic actuator (cylinder) to achieve fluid control. Pneumatic drive enables the valve to be operated quickly and remotely, making it suitable for working conditions with high automation requirements and need rapid response.

Key components.

- Pneumatic actuator: receives air signals to drive the valve stem via piston movement.

- V-port ball: the V-notch adjusts flow by changing contact area with the seat.

- Valve seat: forms a sealing surface with the ball.

- Accessories: solenoid valves, limit switches, positioners, etc., to control the pneumatic actuator and provide feedback information on the valve’s status .

2. Electric V ball valve.

Overview

The electric V ball valve realizes precise regulation and control of fluid flow by driving the V-port ball to rotate through an electric actuator. Similar to the pneumatic V ball valve, the electric V ball valve also has a V-port ball, which has a V-shaped opening at its center. By rotating the ball, the flow cross-sectional area at the valve seat is changed, so as to achieve the on-off and throttling control of the fluid. The electric V ball valve is suitable for high-accuracy, intelligent control scenarios.

Key components.

- Electric actuator: comprises a motor, speed reducer, and position feedback device, driven by electrical signals from the control system.

- V-port ball: adjusts flow by rotating to change the flow area.

- Valve seat: forms a sealing surface with the ball.

- Control system: includes servo amplifiers and controllers which are used to receive input signals and output control commands, and can achieve precise control of the valve opening through built-in algorithms such as PID.

V. Applications of the V ball valve.

- General applications: V ball valves are widely used in chemical, petroleum, metallurgy, power, pharmaceutical, and other industries for precise flow regulation and on-off control.

- Pneumatic V ball valve: suited for industries like petrochemicals, metallurgy, and environmental protection, especially for media with particles, fibers, or high viscosity, and safe for explosive environments.

- Electric V ball valve: ideal for high-accuracy, intelligent control scenarios in petrochemicals, power, and food industries, where pneumatic drive is unsuitable.

VI. Common faults and solutions of V ball valves.

1. Leakage.

- Causes: worn seals, incomplete closure, damaged sealing surfaces, or improper installation.

- Solutions: replace seals, ensure full closure, repair or replace the seat, and follow installation guidelines.

2. Stiff operation or jamming.

- Causes: impurities accumulation, insufficient lubrication, wear, or corrosion.

- Solutions: clean the valve cavity, lubricate regularly, replace worn parts, and remove rust.

3. Stem leakage.

- Causes: worn stem packing seals.

- Solutions: replace the packing seal or adjust the gland to balance sealing and flexibility.

4. Ball and seat wear.

- Causes: Reduced sealing due to prolonged use.

- Solutions: Grind and repair or replace the ball and seat to ensure a tight fit.

5. Actuator failure (electric/pneumatic)

- Causes: electrical issues (e.g., no power, feedback failure) or pneumatic system malfunctions.

- Solutions: check power supply, repair/replace components, verify control signals, and inspect internal parts.

6. Blockage.

- Causes: impurities or scaling inside the valve.

- Solutions: disassemble and clean the valve, or use chemical/physical methods to remove blockages.

Note: The above are typical faults and solutions. For specific issues, always refer to the equipment manual and analyze based on actual conditions.