Valve Materials and Applications (Material Grades, Temperature and Pressure)

Common valve materials table.

The following table shows the composition, standard, application, and temperature of verious common valve materials, which can help us to seize a quick understanding of different valve materials.

| Material | Composition | Standard | Application | Temperature Range |

|---|---|---|---|---|

| WCB | Carbon Steel | ASTM A216 | Non-corrosive media (water, oil, gas) | -30℃ to +425℃ |

| LCB | Low-Temperature Carbon Steel | ASTM A352 | Low-temperature applications (down to -46℃) | Not suitable for >+340℃ |

| LC3 | 3.5% Nickel Steel | ASTM A352 | Low-temperature applications (down to -101℃) | Not suitable for >+340℃ |

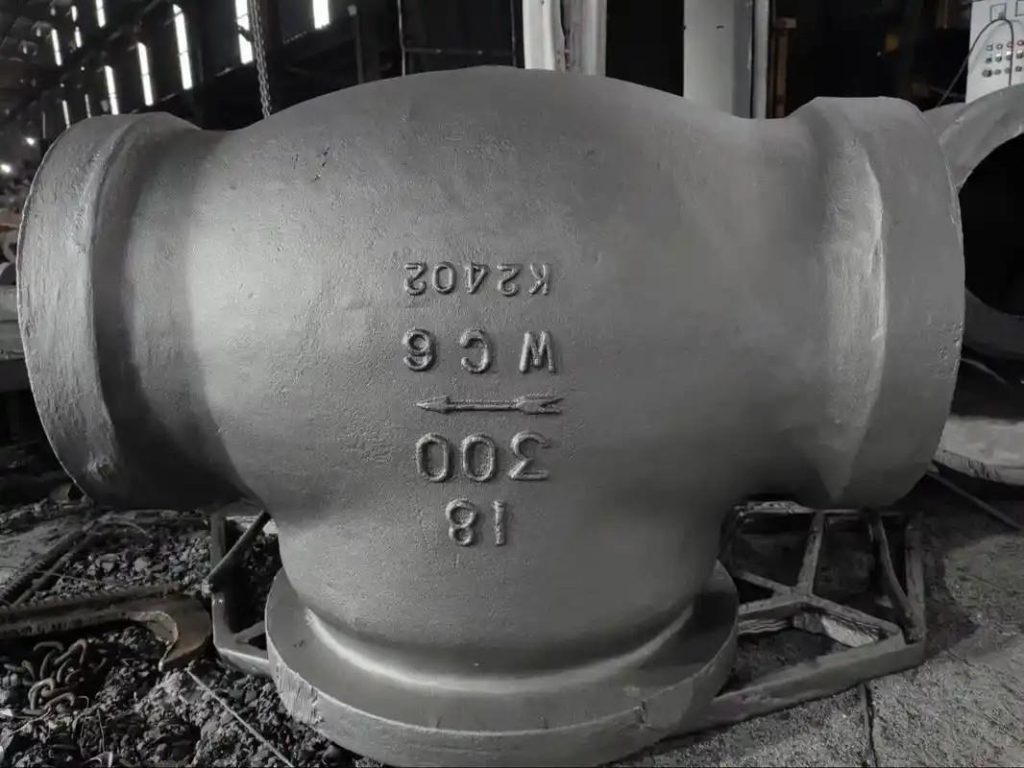

| WC6 | 1.25% Chromium, 0.5% Molybdenum Steel | ASTM A217 | Non-corrosive media (water, oil, gas) | -30℃ to +593℃ |

| WC9 | 2.25% Chromium Steel | ASTM A217 | Non-corrosive media (water, oil, gas) | -30℃ to +593℃ |

| C5 | 5% Chromium, 0.5% Molybdenum | ASTM A217 | Mildly corrosive/erosive or non-corrosive media | -30℃ to +649℃ |

| C12 | 9% Chromium, 1% Molybdenum | ASTM A217 | Mildly corrosive/erosive or non-corrosive media | -30℃ to +649℃ |

| CA6NM (4) | 12% Chromium Steel | ASTM A487 | Corrosive media | -30℃ to +482℃ |

| CA15 (4) | 12% Chromium Steel | ASTM A217 | Corrosive media | Up to +704℃ |

| CF8M | 316 Stainless Steel | ASTM A351 | Corrosive, cryogenic, or high-temperature non-corrosive media | -268℃ to +649℃ (C content ≥0.04% required for >+425℃) |

| CF8C | 347 Stainless Steel | ASTM A351 | Mainly for high-temperature corrosive media | -268℃ to +649℃ (C content ≥0.04% required for >+540℃) |

| CF8 | 304 Stainless Steel | ASTM A351 | Corrosive, cryogenic, or high-temperature non-corrosive media | -268℃ to +649℃ (C content ≥0.04% required for >+425℃) |

| CF3 | 304L Stainless Steel | ASTM A351 | Corrosive or non-corrosive media | Up to +425℃ |

| CF3M | 316L Stainless Steel | ASTM A351 | Corrosive or non-corrosive media | Up to +454℃ |

| CN7M | Alloy Steel | ASTM A351 | Excellent resistance to hot sulfuric acid | Up to +425℃ |

| M35-1 | Monel | ASTM A494 | Weldable grade; resistant to common organic acids, saltwater, and most alkaline solutions | Up to +400℃ |

| N7M | Hastelloy B | ASTM A494 | Ideal for hydrofluoric acid of various concentrations and temperatures; resistant to sulfuric and phosphoric acids | Up to +649℃ |

| CW6M | Hastelloy C | ASTM A494 | Resistant to strong oxidizing environments; excellent performance in high-temperature ; resistant to formic acid, phosphoric acid, sulfurous acid, and sulfuric acid | Up to +649℃ |

| CY40 | Inconel | ASTM A494 | Superior performance in high-temperature and highly corrosive media |

General names and characteristics of different valve materials.

- Gray Cast Iron.

- Suitable for PN ≤ 1.0MPa, -10℃ to 200℃ media (water, steam, air, gas, oil).

- Common grades: HT200, HT250, HT300, HT350.

- Malleable Cast Iron.

- Suitable for PN ≤ 2.5MPa, -30℃ to 300℃ media (water, steam, air, oil).

- Common grades: KTH300-06, KTH330-08, KTH350-10.

- Ductile Iron.

- Suitable for PN ≤ 4.0MPa, -30℃ to 350℃ media (water, steam, air, oil).

- Common grades: QT400-15, QT450-10, QT500-7.

- Note: It is recommended to use steel valves for PN ≤ 2.5MPa for safety.

- Acid-Resistant High-Silicon Ductile Iron.

- Suitable for PN ≤ 0.25MPa, <120℃ corrosive media.

- Carbon Steel.

- Suitable for PN ≤ 32.0MPa, -30℃ to 425℃ media (water, steam, air, hydrogen, ammonia, nitrogen, petroleum products).

- Common grades: WC1, WCB, ZG25, 20, 25, 30 carbon steel, and 16Mn low-alloy steel.

- Copper Alloys.

- Suitable for PN ≤ 2.5MPa, -40℃ to 250℃ media (water, seawater, oxygen, air, oil, steam).

- Common grades: ZGnSn10Zn2 (tin bronze), H62, Hpb59-1 (brass), QAZ19-2, QA19-4 (aluminum bronze).

- High-Temperature Steel.

- Suitable for PN ≤ 17.0MPa, ≤570℃ steam and petroleum products.

- Common grades: ZGCr5Mo, 1Cr5Mo, ZG20CrMoV, ZG15Gr1Mo1V, 12CrMoV, WC6, WC9 (selected per pressure-temperature specifications).

- Low-Temperature Steel.

- Suitable for PN ≤ 6.4MPa, ≥-196℃ media (ethylene, propylene, LNG, liquid nitrogen).

- Common grades: ZG1Cr18Ni9, 0Cr18Ni9, 1Cr18Ni9Ti, ZG0Cr18Ni9.

- Stainless Acid-Resistant Steel.

- Suitable for PN ≤ 6.4MPa, ≤200℃ media (nitric acid, acetic acid).

- Common grades: ZG0Cr18Ni9Ti, ZG0Cr18Ni10 (nitric acid-resistant), ZG0Cr18Ni12Mo2Ti, ZG1Cr18Ni12Mo2Ti (acid and urea-resistant).

Relationship between valve materials, temperature, and pressure.

1. Service temperature of valves.

The service temperature of a valve is determined by the material used in its manufacture. The service temperatures of common valve materials are as follows:

| Valve Material | Temperature Range |

|---|---|

| Gray Cast Iron Valves | -15℃ to 250℃ |

| Malleable Cast Iron Valves | -15℃ to 250℃ |

| Ductile Iron Valves | -30℃ to 350℃ |

| High-Nickel Cast Iron Valves | Up to 400℃ |

| Carbon Steel Valves | -29℃ to 450℃ (JB/T3595-93 recommends ≤425℃) |

| 1Cr5Mo Alloy Steel Valves | Up to 550℃ |

| 12Cr1MoVA Alloy Steel Valves | Up to 570℃ |

| 1Cr18Ni9Ti/1Cr18Ni12Mo2Ti Stainless Steel Valves | -196℃ to 600℃ |

| Copper Alloy Valves | -273℃ to 250℃ |

| Plastic Valves (Nylon) | Up to 100℃ |

| Plastic Valves (Chlorinated Polyether) | Up to 100℃ |

| Plastic Valves (PVC) | Up to 60℃ |

| Plastic Valves (PCTFE) | -60℃ to 120℃ |

| Plastic Valves (PTFE) | -180℃ to 150℃ |

| Plastic Valves (Natural Rubber Diaphragm) | Up to 60℃ |

| Plastic Valves (NBR/CR Diaphragm) | Up to 80℃ |

| Plastic Valves (Fluororubber Diaphragm) | Up to 200℃ |

2. Limitations of valves by spesific valve materials:

- Rubber/plastic linings: subjected to the temperature resistance of rubber/plastic.

- Ceramic valves: generally ≤150℃ (new super-performance ceramics can withstand ≤1000℃).

- Glass valves: ≤90℃ due to poor thermal shock resistance.

- Enamel valves: ≤150℃ limited by sealing materials.

3. Service pressure of valves.

| Valve Material | Maximum Allowable Nominal Pressure |

|---|---|

| Gray Cast Iron Valves | 1MPa |

| Malleable Cast Iron Valves | 2.5MPa |

| Ductile Iron Valves | 4.0MPa |

| Copper Alloy Valves | 2.5MPa |

| Titanium Alloy Valves | 2.5MPa |

| Carbon Steel Valves | 32MPa |

| Alloy Steel Valves | 300MPa* |

| Stainless Steel Valves | 32MPa |

| Plastic Valves | 0.6MPa |

| Ceramic/Glass/Enamel Valves | 0.6MPa |

| FRP (Fiberglass) Valves | 1.6MPa |

4. Relationship Between Temperature and Pressure.

Temperature is the dominant factor: A valve with a specific pressure rating is only suitable for a specific temperature range, and temperature changes affect its service pressure.

For Example: A carbon steel valve with PN 10MPa:

- At 200℃, maximum working pressure P20 = 10MPa;

- At 400℃, maximum working pressure P40 = 5.4MPa;

- At 450℃, maximum working pressure P45 = 4.5