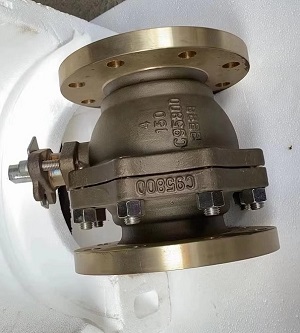

Flanged Type Bronze API 6D Ball Valve

The main material of a bronze ball valve is bronze, including cast aluminum bronze and aluminum bronze, etc. Bronze materials have good corrosion resistance, wear resistance and impact resistance, and can withstand the erosion of various corrosive media such as seawater, sulfates and chlorides. The structure of a ball valve usually includes key components such as the valve body, valve cover, valve stem and ball, all of which are made of bronze to ensure the overall durability and reliability of the valve.

Our floating ball valves are designed, engineered and manufactured in strict conformance to API, ASTM, ASME, ANSI and other recognized standards.

Main features of bronze API 6D ball valve.

- Two Piece or Three Piece

- Bore Type – Reduced Bore or Full Bore

- Anti- Static Device

- Blow- Out Proof Stem

- Fire Safe Design

- Low Emission

Product Parameter

| Size | ½” up to 10″(DN 15 up to DN 250) |

| Pressure Rating | ASME 150# to 2500# |

| • ½” to 10″ – 150# | |

| • ½” to 8″ – 300# | |

| • ½” to 4″ – 600# | |

| • ½” to 1 ½” – 900#, 1500# & 2500# | |

| Materials | Carbon Steel, Low Temperature Carbon Steel, Stainless Steel, Duplex Stainless Steel, Super Duplex Stainless Steel, Nickel Alloys, Nickel Aluminum Bronze, Hastelloy, Inconel Etc. |

| Seating | Soft Seated (PTFE/RPTFE /PEEK/NYLON/DEVLON) and Metal Seated |

| End Connection | Flanged RF/RTJ, BW, FNPT & SW Ends |

| Operator | Lever/Wrench, Gear Operated |

Specification & Standards

| Design | API 6D / API 608 / BS5351 / ASME B16.34 |

| Face to Face | ASME B16.10 |

| End Flange | ASME B16.5 |

| BW End | ASME B16.25 |

| Test | API598/API6D |

| Fire Safe Test | API607/API6FA |

| Special | NACE MR-01-75 |

The data is for reference only, please consult sales@wayvalve.com for details.

The applications of Bronze API 6D Ball Valve.

Bronze ball valves are widely used in industrial fields such as marine, chemical, petroleum, and natural gas.

What is the difference between API 608 and API 6D ball valve?

API 608 and API 6D ball valves differ primarily in application scope and design standards:

API 608 covers general-purpose ball valves for various industries (e.g., chemical, petroleum), suitable for moderate pressure/temperature conditions. It allows both metal and soft seats, with options for flanged, threaded, or welded ends.

API 6D specifies valves for pipeline systems (e.g., oil/gas transmission), emphasizing ruggedness for harsh, high-pressure/high-temperature environments. It requires metal seats and focuses on pipeline-specific features like direct burial and pigging capability.

In summary, API 608 is more versatile for general industrial use, while API 6D is specialized for pipeline applications with stricter durability and operational requirements.

INQUIRY