A Comparison of the Advantages and Disadvantages of Butterfly Valves and Gate Valves

In a fluid pipeline system, valves are essential parts, playing a crucial role in the controlling of flow rate, pressure, and flow direction of the fluid. Among verious types of valves, butterfly valves and gate valves are sure two common choices. However, there are many differences between both valves in terms of appearance, structure, working principle, and application scenarios.

Here below is an in depth comparative analysis of these two types of valves from multiple perspectives.

[I] In terms of appearance and structure, butterfly valves and gate valves present different characteristics.

- [1] The butterfly valve stands out with its unique fan-shaped valve plate design. The valve plate can rotate around the central axis, thus realizing the control of the fluid.

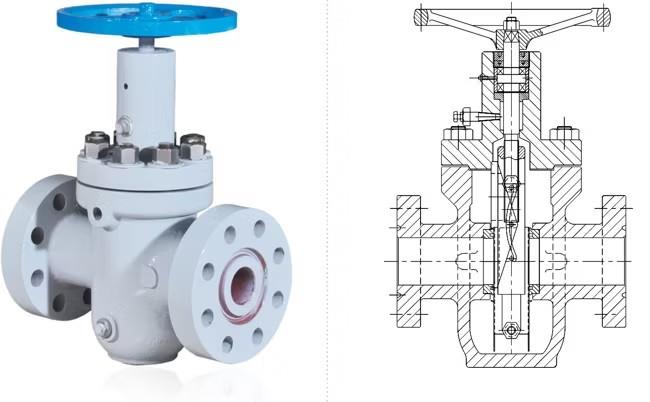

- [2] The valve plate of the gate valve is rectangular in shape and controls the opening and closing of the fluid through vertical lifting movements.

This difference in structure not only makes them different in appearance but also determines the differences in their working principles.

[II] In terms of the working principle.

- [1] The butterfly valve drives the opening and closing of the valve plate by rotating the valve stem, thus achieving the regulation of the fluid.

- [2] The gate valve controls the opening and closing of the fluid by lifting the valve plate. When the valve plate rises, the fluid can pass through; when the valve plate descends, the fluid is blocked.

These two different working principles result in differences in the applicable scenarios of butterfly valves and gate valves.

[III] In terms of application scenarios.

- [1] Due to its simple structure, small size, light weight, and easy operation, the butterfly valve is widely used in the water systems or ventilation systems of commercial buildings, public buildings, and urban pipeline networks.

- [2] The gate valve, because of its outstanding sealing performance, small fluid resistance, and strong flow capacity, is often used in special scenarios such as high temperature and high pressure environments, high viscosity fluids, and situations prone to scaling.

[IV] Each type of valve has its own advantages and disadvantages.

- [1] The advantages of the butterfly valve lie in its simple structure, small size, light weight, and convenience for installation and maintenance. It also has good sealing performance and plays a good role in regulating the flow rate for large diameter pipelines. However, the pressure bearing capacity of the butterfly valve is relatively weak, and it has a relatively large resistance to high speed flowing fluids.

- [2] In contrast, the advantages of the gate valve are good sealing performance, small fluid resistance, strong flow capacity, and the ability to withstand high pressure and temperature. However, its disadvantages are also obvious. It is large in size, heavy in weight, and relatively complex in installation and maintenance.

In general, there are significant differences between butterfly valves and gate valves in terms of appearance, structure, working principle, and application scenarios. Which valve to choose needs to be determined according to the specific requirements of the fluid pipeline system. Whether it is the lightweight and easy-to-operate butterfly valve or the gate valve that can withstand high pressure and temperature, each has its unique advantages and applicable scenarios.

Therefore, when purchasing valves, we need to fully understand the performance characteristics of various valves to ensure that the valve we choosed is suitable for needs.