Introduction to the Slab Gate Valve.

Ⅰ.What is a slab gate valve?

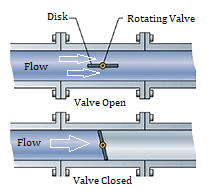

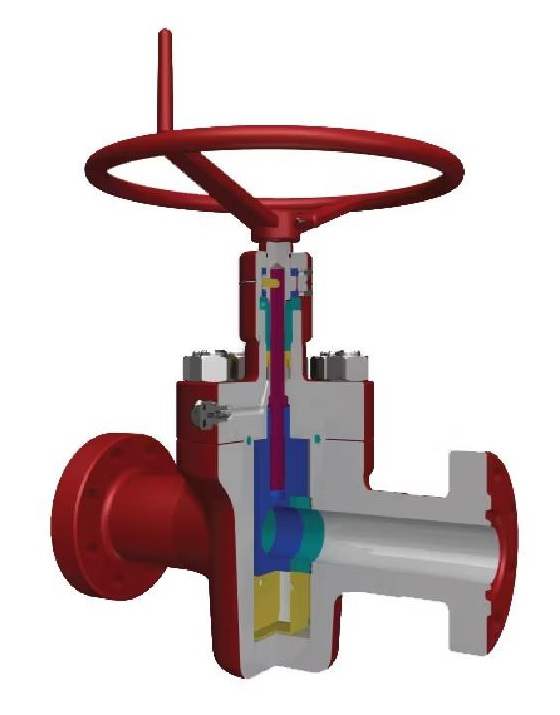

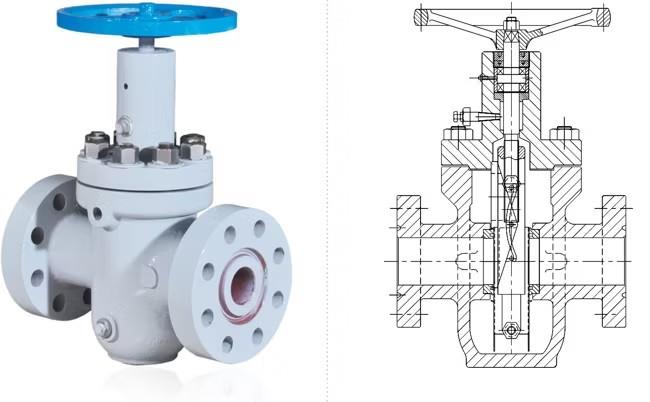

The slab gate valve uses a plate-shaped gate as the opening and closing component, achieving switching through the linear motion of the gate along a direction perpendicular to the fluid.

Its remarkable features in structure are:

- Parallel sealing surfaces: The sealing surfaces of the gate and valve seat are parallel and closely fitted. With metal hard-sealing or elastic sealing designs, it is suitable for high-pressure environments and media containing particles.

- Straight flow passage: When fully open, the passage is unobstructed, resulting in low fluid resistance and pressure drop loss, making it suitable for large flow conditions.

Gate valves are generally being completely on and off. It can not used for throttling. The slab gate valve that we are going to talk about today is generally applicable to chemical industry, petroleum, natural gas, environmental protection, city underground pipeline, city gas pipeline and other relevant transmission lines. As for the venting system and the steam storage equipment, it mainly serves as a switch gear.

Ⅱ.Types of slab gate valve.

| Classification Basis | Specific Categories Gate Valve | Characteristics and Applications |

| Sealing | Metal hard sealing | Resistant to high pressure and temperature, suitable for harsh working conditions such as oil and gas, chemical industries (e.g., valves compliant with API 6D standard). |

| Elastic sealing (soft sealing) | Sealing surfaces contain elastic materials like rubber, with extremely low leakage, suitable for clean media (e.g., urban gas). | |

| Gate Structure | Single gate | Simple structure and low cost, applicable to small and medium diameters. |

| Double gate (parallel type) | The two side gates are fitted to the valve seat through spring or medium pressure, with high sealing reliability, suitable for large-diameter pipelines. | |

| Connection Mode | Flanged, butt-welded, socket-welded | Flanged connection is convenient for installation and maintenance; butt-welded type is suitable for high-pressure pipelines (e.g., petroleum pipelines). |

Ⅲ.The main features of slab gate valves :

- 1. The integral sealing structure of the slab-style gate valve seat shall have an elastic pre-tightening force and be able to seal the upper and lower sealing seats at the same time. The seat is forever face to face with the sealed object.

- 2. The seat is self-cleaning and free from being scoured by the air flow coming from the switch on-and-off. It shall be made of lubricated and abrasion resistant materials.

- 3. The failure of the slab-style gate valve actuator is isolated from other parts, which enables the repair and replacement to be carried out without taking it apart.

- The Yoke Sleeve: The aluminum bronze toke sleeves are generally equipped with needle thrust bearings so that it can minimize torque during operation.

- The Valve Stem: The screw thread covers the slab gate stem up to the bracket. Its pin is spot welded, which ensures a high stability.

- The Pressure Sealed Seat: The overall design is simple with segmented retaining rings and silver-plated low carbon steel gaskets to facilitate the later disassembly and to achieve an excellent bonnet seal.

- 4. The body of a slab gate valve is usually cast or welded.

- 5. The seat of the slab gate valve is sealed by an O-ring together with the pre-tightening force, which seals both ways in and out of the valve. The stroke in this structure is half that of an ordinary gate valve, therefore it is easy to switch on-and-off.

- 6. For a metal-sealed slab gate valve, outside of the valve body is generally provided with a grease-filling inlet. By the grease injector, the grease gets into the sealing surface through the seat to achieve the zero percent of leakage.

The gate of the slab gate valve is a rectangular parallel plate with a through-hole of the same diameter as the passage. Once it is fully opened, the passage will be smooth and straight with a relatively low coefficient of flow resistance, which lessen the pressure loss. The wedge is always in contact with the seat in the process of switch on-and-off so that tiny particles clinging on the sealing surface can be wiped away. Moreover, the whole sealing surface is under protect, since it is free form being washed by a variety of media.

Ⅳ.Slab gate valve vs gate valve.

Slab gate valves and common gate valves(mainly refer to the wedge gate valve) exhibit distinct differences in structure, application, and performance. One should select appropriate products based on specific needs when making purchases.

Structure differences.

- Slab gate valve.

- The slab gate valve realizes opening and closing through a flat plate structure. It features a sealing ring installed on the valve disc plate, ensuring sealing quality and safety. Slab gate valves are categorized into two types: single-directional closed and bidirectional closed.

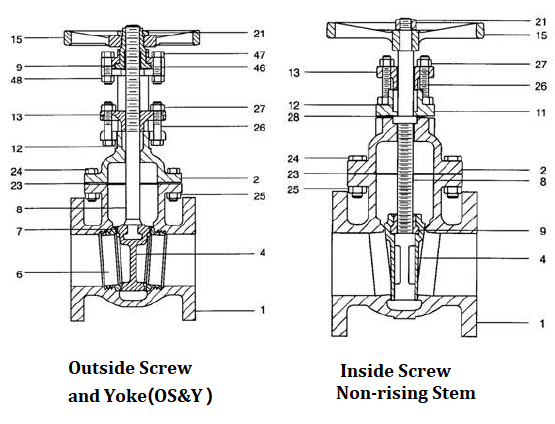

- Common gate valve.

- Compared with slab gate valve, the common gate valve has a simpler structure. The valve plate lacks a sealing ring, making it prone to leakage during use. Its structure typically adopts threaded or flanged connections.

Divergent applications.

- Slab gate valve

- Due to its excellent sealing performance and safety reliability, slab gate valves are commonly used in high-pressure, high-temperature, and strongly corrosive environments, such as chemical, petroleum, and power industries.

- Common gate valve.

- Common gate valves are suitable for general working conditions, such as clean water pipelines, sewage pipelines, and gas pipelines.

Performance disparities.

- Slab gate valve.

- The slab gate valve demonstrates superior sealing performance, effectively preventing leakage during operation. Additionally, it features a fast closing speed, making it suitable for scenarios requiring rapid fluid cutoff.

- Common gate valve.

- Owing to its simple structure, the common gate valve has a relatively lower cost. However, its sealing performance and safety are poorer, making it suitable for pipelines under low-flow and low-pressure conditions.

Ⅴ.Slab type gate valve vs other valves.

| Valve Type | Flow Resistance | Sealing Performance | Applicability to Particles | Pressure Range |

|---|---|---|---|---|

| Slab Type Gate Valve | Low | Good (hard/elastic) | High | Wide (low to high) |

| Globe Valve | High | Excellent | Low | Medium to high |

| Ball Valve | Very low | Excellent | Medium | Medium to high |