Angle Move Flange Electric Actuated Butterfly Valve.

A butterfly valve with electric actuator is mainly composed of valve body, valve plate, and an electric actuator. Its function is to open, close the valve and regulate the flow rate of the mediummeet the requirements of various technological processes.

Compared with manual valves, the butterfly valve with electric actuator has a remote control function. It can be connected to control systems such as Programmable Logic Controllers (PLC) and Distributed Control Systems (DCS) via wired or wireless means, enabling remote operation and monitoring. This greatly improves the convenience and flexibility of operation, making it suitable for industrial production processes with a high degree of automation. In addition, this actuated butterfly valve supports multiple control modes and signal compatibility, allowing it to better interface with various industrial automation control systems.

Main features of the electric actuated butterfly valve.

- If no special request, the electric butterfly valve is usually equipped with a German AUMA electric actuator. Our goal is to make products with good and reliable quality, and for the user in the long-term use of reducing the maintenance costs of the pipeline;

- This valves adopts hard sealed valve seat. The hard sealed valve seat surface can be surfacing welded to prevent the valve from being unable to be sealed due to damage to the valve seat and sealing surface by strong abrasive media;

- The stem is designed in the anti blow out, preventing the stem blow out at the time of maintenance ;

- The material is produced in accordance with international standards;

- Savings in labor;

- Plant safety;

- Product quality assurance;

- Automatic sequencing.

Product Parameters

| Optional electric actuator features | Switch type, integral type, regulating type, intelligent type |

| Optional electric actuator models | Q,DQ,QM,QC,AKQSeries, large diameter optionalZseries,AKseries |

| Voltage | AC220V, AC110V, AC380, DC12V, DC24V, DC110V |

| Nominal diameter | DN40mm~DN1400mm |

| Nominal pressure | PN1.0MPa~PN1.6MPa |

| proper temperature | EPDM:-30~+100ºC PTEE: -30~+120ºC |

| Connection | Flange |

| Valve body material | Ductile iron, carbon steel, stainless steel |

| Valve plate material | Spheroidal ink,304,316,316L,2507,1.4529, copper plate, nylon, etc. |

| Valve seat lining | NBR,EPDM,PTFE |

| Applicable media | Water, gas, slurry, oil, etc. |

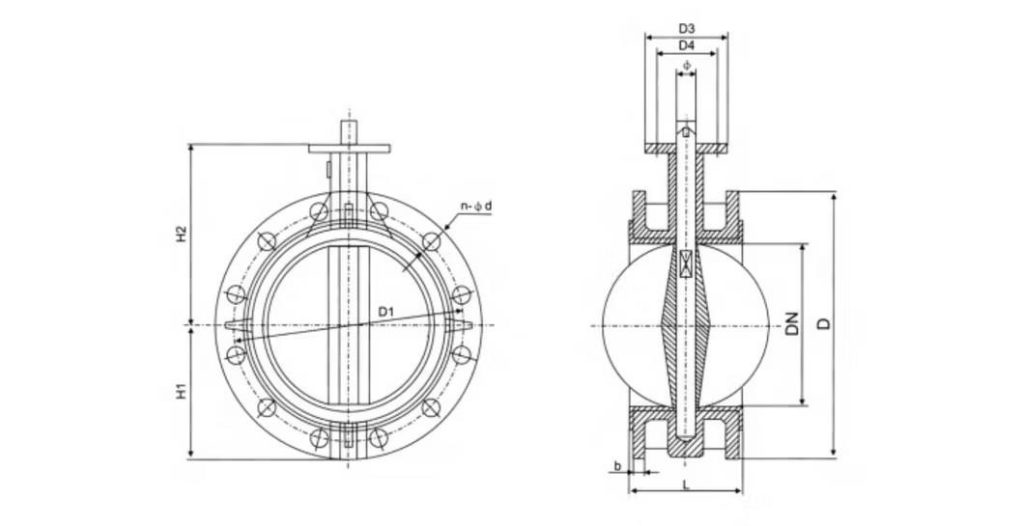

Dimensions

| DN (mm) | D | D1 | L | D3 | D4 | H1 | H2 | Φ | b | N-Φd | |||

| 1 | 1.6 | 1 | 1.6 | 1 | 1.6 | ||||||||

| 50 | 165 | 165 | 125 | 125 | 108 | 70 | 50 | 83 | 130 | 12.7 | 18 | 4-Φ18 | 4-Φ18 |

| 65 | 185 | 185 | 145 | 145 | 112 | 70 | 50 | 93 | 140 | 12.7 | 18 | 4-Φ18 | 4-Φ18 |

| 80 | 200 | 200 | 160 | 160 | 114 | 70 | 50 | 100 | 150 | 12.7 | 20 | 8-Φ18 | 8-Φ18 |

| 100 | 220 | 220 | 180 | 180 | 127 | 90 | 70 | 110 | 165 | 15.8 | 20 | 8-Φ18 | 8-Φ18 |

| 125 | 250 | 250 | 210 | 210 | 140 | 90 | 70 | 123 | 180 | 19.05 | 22 | 8-Φ18 | 8-Φ18 |

| 150 | 285 | 285 | 240 | 240 | 140 | 90 | 70 | 143 | 200 | 19.05 | 22 | 8-Φ22 | 8-Φ22 |

| 200 | 340 | 340 | 295 | 295 | 152 | 125 | 102 | 171 | 230 | 22.2 | 24 | 8-Φ22 | 12-Φ22 |

| 250 | 390 | 405 | 350 | 355 | 165 | 125 | 102 | 203 | 270 | 28.6 | 24 | 12-Φ22 | 12-Φ26 |

| 300 | 440 | 460 | 400 | 410 | 178 | 150 | 125 | 230 | 320 | 31.8 | 26 | 12-Φ22 | 12-Φ26 |

| 350 | 500 | 520 | 460 | 470 | 190 | 150 | 125 | 260 | 350 | 31.8 | 26 | 16-Φ22 | 16-Φ26 |

| 400 | 565 | 580 | 515 | 525 | 216 | 175 | 140 | 300 | 390 | 33.34 | 28 | 16-Φ26 | 16-Φ30 |

| 450 | 615 | 640 | 565 | 585 | 222 | 175 | 140 | 335 | 428 | 38 | 30 | 20-Φ26 | 20-Φ30 |

| 500 | 670 | 715 | 620 | 650 | 229 | 210 | 165 | 373 | 450 | 41.15 | 32 | 20-Φ26 | 20-Φ33 |

| 600 | 780 | 840 | 725 | 770 | 267 | 210 | 165 | 430 | 520 | 50.7 | 34 | 20-Φ30 | 20-Φ36 |

| 700 | 895 | 910 | 840 | 840 | 292 | 300 | 254 | 470 | 600 | 55 | 36 | 24-Φ30 | 24-Φ36 |

| 800 | 1015 | 1025 | 950 | 950 | 318 | 300 | 254 | 523 | 662 | 63.35 | 36 | 24-Φ30 | 24-Φ39 |

| 900 | 1115 | 1125 | 1050 | 1050 | 330 | 300 | 254 | 589 | 710 | 75 | 40 | 26-Φ33 | 28-Φ39 |

| 1000 | 1230 | 1255 | 1160 | 1170 | 410 | 300 | 254 | 656 | 780 | 85 | 42 | 26-Φ36 | 28-Φ42 |

| 1200 | 1405 | 1485 | 1340 | 1390 | 470 | 300 | 254 | 732 | 840 | 92 | 46 | 32-Φ37 | 32-Φ49 |

| 1400 | 1630 | 1685 | 1560 | 1590 | 530 | 300 | 254 | 840 | 905 | 130 | 50 | 36-Φ37 | 36-Φ49 |

The data is for reference only, please consult sales@wayvalve.com for details.

The butterfly valve with electric actuator has been widely applied in numerous fields, including:

- Metallurgy and Building Materials Field

- Industrial Automation Field

- Water Supply, Drainage and Water Treatment Field

- Heating, Ventilation and Air Conditioning (HVAC) Field

- Food, Beverage and Pharmaceutical Field

- Papermaking and Printing and Dyeing Field

What is the electric actuated butterfly valve?

The butterfly valve butterfly valve is widely used in various industrial and commercial applications. It consists of a disc-shaped closure element that rotates within a valve body to control the flow of fluids, such as water, gas, or oil. What makes it special is its electric actuator, which allows for remote-controlled or automated operation. This actuator can be programmed to open and close the valve at specific times or in response to certain process conditions. Electric butterfly valves offer advantages like high-precision flow control, quick response times, and the ability to be integrated into complex control systems. They are known for their reliability, low maintenance requirements, and good sealing performance, making them an essential component in many fluid-handling systems.

INQUIRY