Rising Stem Metal Seated Gate Valve DIN3352 F4

The rising stem metal seated gate valve is a common type of valve, mainly used for full-open and full-closed operations, and cannot be used for regulation and throttling. Its opening and closing element is the gate plate, and the movement direction of the gate plate is perpendicular to the fluid direction. In the rising stem metal-seated gate valve, the valve stem nut is located on the valve cover or the bracket. When opening or closing the gate plate, the valve stem is raised or lowered by rotating the valve stem nut. This structure is beneficial for the lubrication of the valve stem, and the opening and closing degree is clearly visible.

Main features of DIN3352 F4 rising stem metal seated gate valves.

- Reasonable product structure and reliable sealing.

- German standard rising stem metal-seated gate valves adopt a double durable bellows sealing design (bellows + packing), which ensures zero leakage of the valve stem and no fluid loss. This improves the safety of factory equipment and meets international sealing standards.

- Excellent sealing surface material.

- The sealing surface is overlaid with grass, which features good elasticity, corrosion resistance, high mechanical strength, good thermal conductivity, economical costs, and easy replacement.

- Advanced valve stem treatment technology. The valve stem is quenched and tempered and surface-nitrided, having good corrosion resistance and anti-friction performance. In addition, there are indicators for the lifting position of the valve stem, making the operation more intuitive.

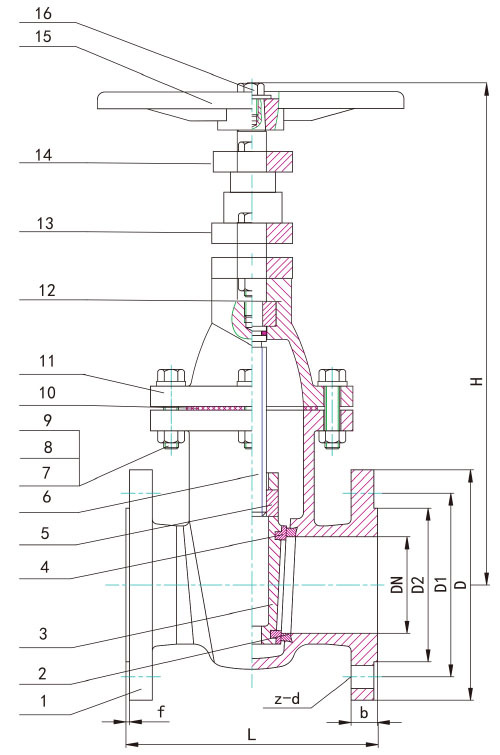

Parts and Material

| No | Part | Material |

| 1 | Body | Gray Cast Iron GG25 | |

| 2 | Body Seat Ring | Brass | |

| 3 | Wedge | Gray Cast Iron GG25 | |

| 4 | Wedge Seat Ring | Brass | |

| 5 | Stem Nut | Brass | |

| 6 | Stem | SS420 | |

| 7 | Bonnet Bolt | Carbon Steel | |

| 8 | Nut | Carbon Steel | |

| 9 | Washer | Carbon Steel | |

| 10 | Gasket | Graphite | |

| 11 | Bonnet | Gray Cast Iron GG25 | |

| 12 | Minipad | Graphite | |

| 13 | Gland | Gray Cast Iron GG25 | |

| 14 | Gland | Gray Cast Iron GG25 | |

| 15 | Wheel | Gray Cast Iron GG25 | |

| 16 | Washer | Carbon Steel |

Tenical Specifications

| No | Description | Specification |

| 1 | Nominal Dia | DN40-DN300 |

| 2 | Nominal Pressure | PN10&PN16 |

| 3 | Valve Design Standard | DIN3352/BS5163 |

| 4 | Face to Face Standard | EN558&ISO5752 Series-3/14/15 |

| 5 | Flange Standard Conformity | EN1092-2 |

| 6 | Testing Standard | EN12266-1 |

| 7 | Expoxy Coating | Epoxy powder coating with minimum thickness of 250 microns inside and outside. |

Testing Pressure

| 8 | Shell Test | PN*1.5Times |

| Sealing Test | PN*1.1Times | |

| 9 | Working Temperature(Max) | 180℃ |

Dimensions

| N | L | D | D1 | D2 | n-d | b | f | H | |||||||

| BS5163 | F4 | F5 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | |||

| DN40 | 165 | 140 | 240 | 150 | 110 | 84 | 4-19 | 18 | 3 | 214 | |||||

| DN50 | 178 | 150 | 250 | 165 | 125 | 99 | 4-19 | 20 | 3 | 232 | |||||

| DN65 | 190 | 170 | 270 | 185 | 145 | 119 | 4-19 | 20 | 3 | 258 | |||||

| DN80 | 203 | 180 | 280 | 200 | 160 | 133 | 8-19 | 22 | 3 | 281 | |||||

| DN100 | 229 | 190 | 300 | 220 | 180 | 154 | 8-19 | 24 | 3 | 315 | |||||

| DN125 | 254 | 200 | 325 | 250 | 210 | 184 | 8-19 | 26 | 3 | 358 | |||||

| DN150 | 267 | 210 | 350 | 285 | 240 | 210 | 8-23 | 26 | 3 | 408 | |||||

| DN200 | 292 | 230 | 400 | 340 | 295 | 265 | 8-23 | 12-23 | 30 | 3 | 500 | ||||

| DN250 | 330 | 250 | 450 | 405 | 350 | 355 | 319 | 12-23 | 12-28 | 32 | 3 | 572 | |||

| DN300 | 356 | 270 | 500 | 460 | 400 | 410 | 370 | 12-23 | 12-28 | 32 | 4 | 662 | |||

The data is for reference only, please consult sales@wayvalve.com for details.

The rising stem metal seated gate valve is maily applied in following fields.

It is widely used in fields such as petroleum, chemical industry, water treatment, heating, ventilation and air conditioning (HVAC), water supply and drainage engineering, construction, and fire protection.

What is the difference between rising and non-rising gate valves?

The main differences between rising and non – rising gate valves are as follows:

Structure: In rising gate valves, the valve stem rises and falls with the opening and closing of the valve, and the position of the valve stem nut is usually on the valve cover or bracket. In non – rising gate valves, the valve stem does not rise or fall, but rotates in place to drive the gate plate to move.

Visual indication: Rising gate valves can visually show the opening and closing status of the valve through the position of the rising valve stem. Non – rising gate valves usually need other indicators or markings to show the opening and closing degree.

Application scenarios: Rising gate valves are often used in occasions where the opening and closing status needs to be clearly observed, such as in some large – scale industrial pipelines. Non – rising gate valves are suitable for occasions where space is limited or the valve stem rising is not convenient, such as in some small – diameter pipelines or in relatively confined spaces.

INQUIRY