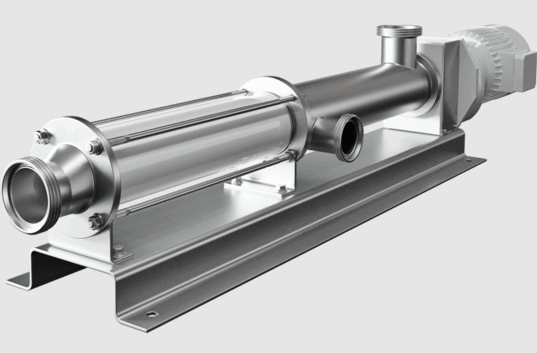

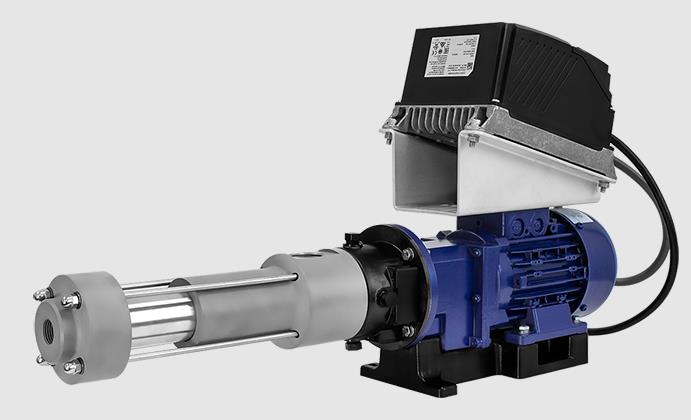

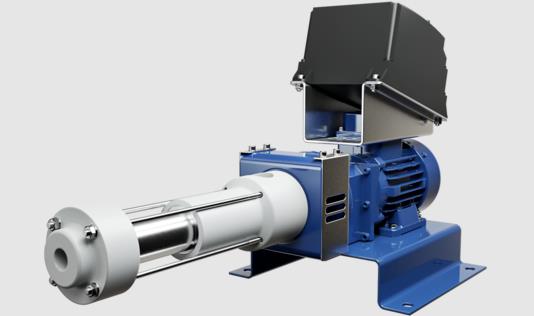

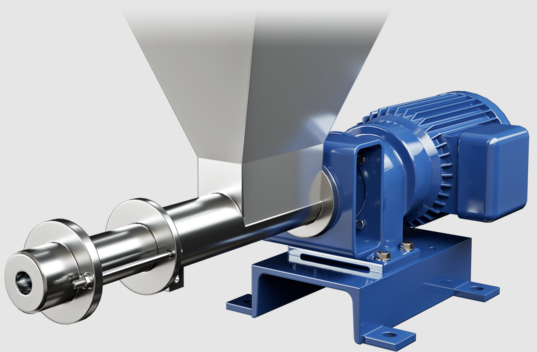

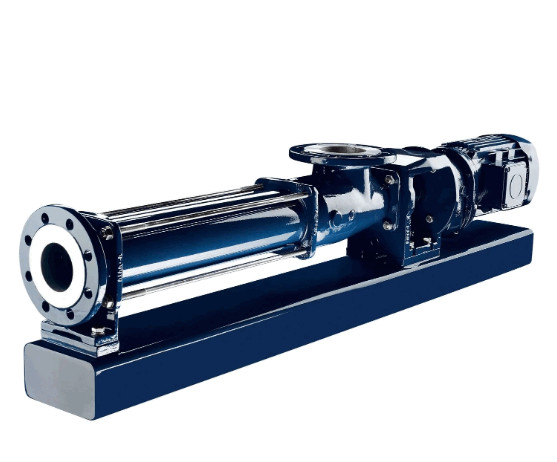

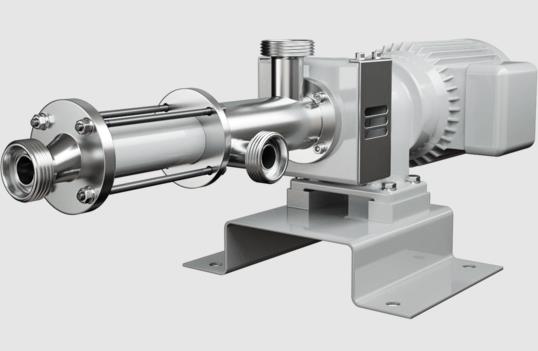

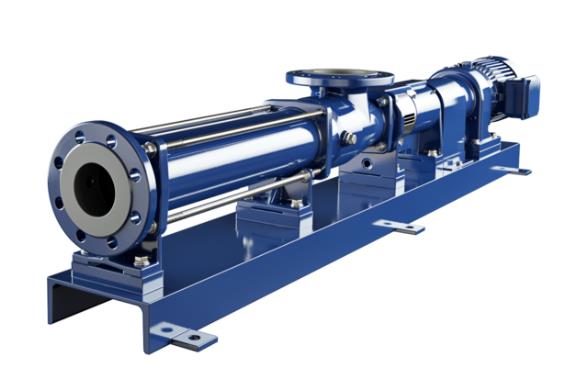

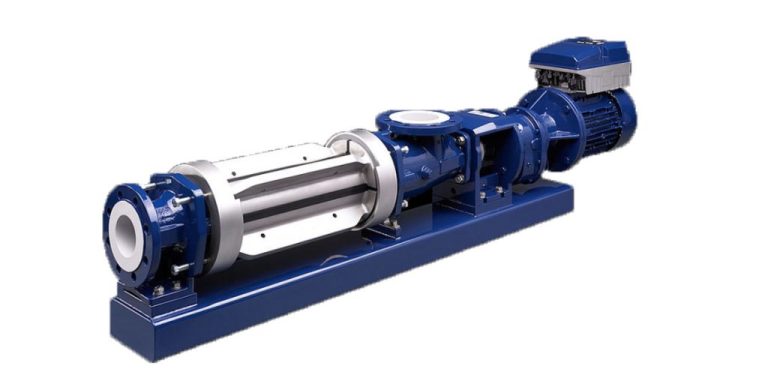

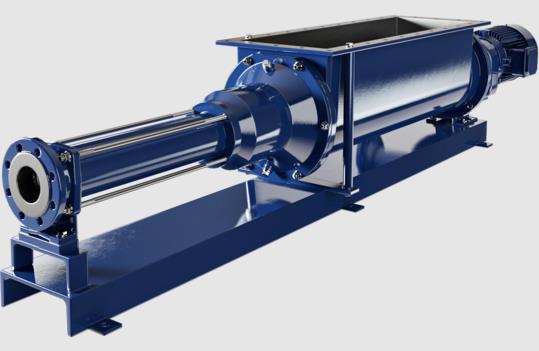

Seepex Pumps Parts

Introduce Seepex Pumps Parts With a focus on precision engineering and superior performance, Seepex Pumps Parts offers a wide range of products, including stators, rotors, coupling rods, and drive shafts. Their products are designed to meet or exceed OEM specifications, ensuring optimal pump performance and reliability. Seepex Pumps Parts is committed to providing exceptional customer…