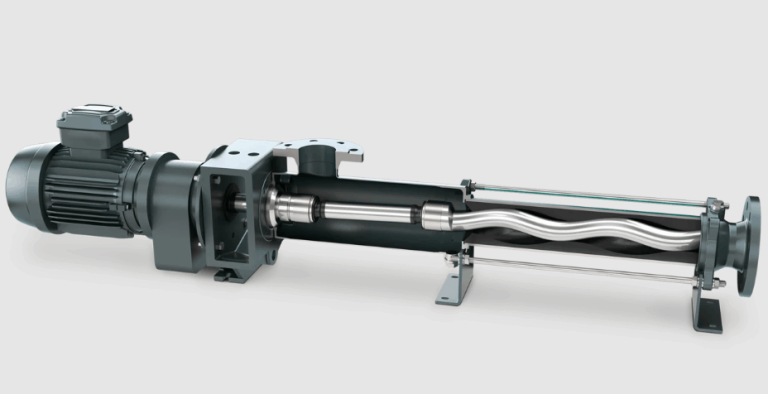

NETZSCH Pump for hygienic applications NEMO® BH

NEMO® BH Hygienic Pump in Compact Block Design The NEMO® BH hygienic pump in compact block design is used for hygienic pump applications in the food, pharmaceutical, cosmetic and chemical/biochemical industries because of its optimal process characteristics . The progressing cavity pump impresses with its continuous, pressure-stable, gentle and low-pulsation conveyance that is independent of…