SEEPEX MDR – Superior Process Control

MDR – Superior Process Control

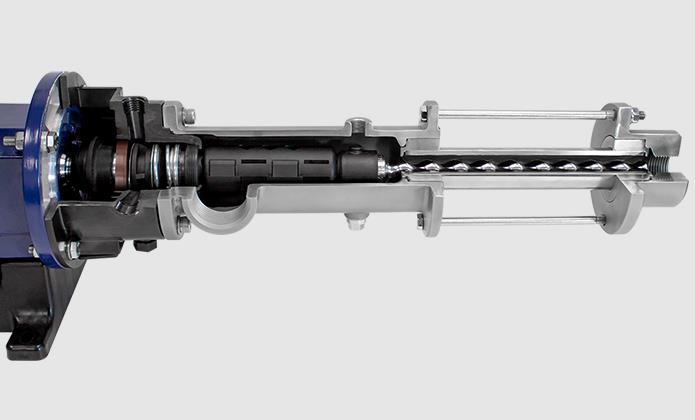

The MDR range design incorporates an external GA seal arrangement and engineered composite seal housing, lantern, and rotating unit. The only metallic part of the pump that is exposed to the conveyed product is the rotor. This design allows for broad chemical compatibility, increased performance, and decreased maintenance.

The patented joint design performs as a constant velocity joint, reducing pulsation to levels only detectable by laboratory equipment. This, combined with progressive cavity pump technology, provides laminar flow and a high degree of accuracy in chemical dosing applications.

Description of MDR – Superior Process Control

SEEPEX MDR – Superior Process Control is a state-of-the-art process control system that offers high precision and real-time monitoring of complex industrial processes. It uses advanced algorithms and data analytics to optimize production and improve efficiency. MDR – Superior Process Control also features a user-friendly interface that allows operators to easily configure and adjust settings, as well as monitor key performance indicators.

Applications of MDR – Superior Process Control

MDR – Superior Process Control is a versatile process control system that can be applied to a range of industries and processes. With its advanced algorithms and real-time monitoring capabilities, it offers precise control and optimization for complex industrial processes. Some common applications of MDR – Superior Process Control include:

- Chemical manufacturing: MDR – Superior Process Control can be used to optimize the production of chemicals such as polymers, plastics, and specialty chemicals. The system provides real-time monitoring of critical parameters such as temperature, pressure, and flow rate, allowing for precise control and consistency in output quality.

- Pharmaceutical manufacturing: The pharmaceutical industry requires strict adherence to regulatory guidelines, and MDR – Superior Process Control can help ensure compliance while optimizing production efficiency. The system’s advanced analytics and user-friendly interface allow for precise control over critical variables such as mixing, blending, and reaction times.

- Food and beverage production: MDR – Superior Process Control can be used in food and beverage processing to optimize product quality, reduce waste, and improve efficiency. The system provides real-time monitoring of key parameters such as pH, temperature, and viscosity, allowing for precise control over the production process.

- Oil and gas production: In the oil and gas industry, MDR – Superior Process Control can be used for tasks such as wellhead automation, pipeline management, and refinery operations. The system’s advanced analytics and real-time monitoring capabilities enable efficient management of complex processes and ensure safety and regulatory compliance.

Overall, MDR – Superior Process Control is a powerful tool for optimizing industrial processes and improving production efficiency across a range of industries. Its advanced features and versatility make it an ideal choice for applications with complex variable interactions and high precision requirements.

Optimized metering and dosing accuracy

The constant velocity joint reduces pulsation to levels only detectable by laboratory equipment

Superior performance and longevity

Provided by chemically inert materials of construction

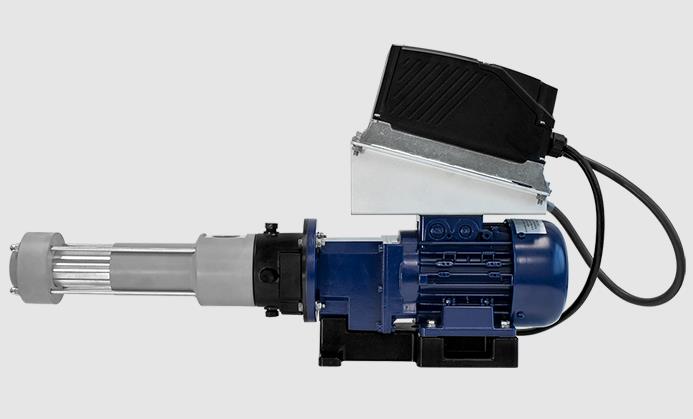

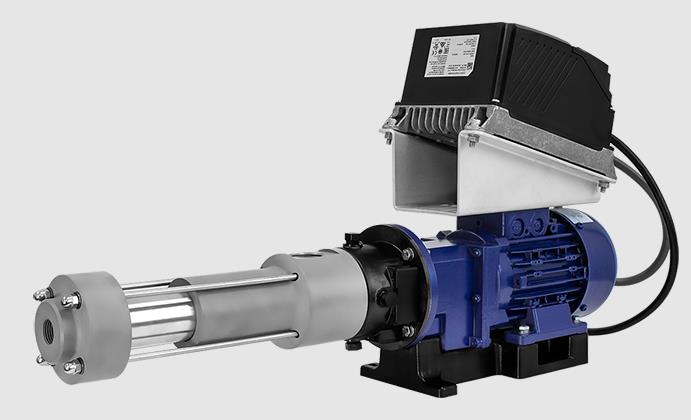

Available in Intelligent Metering Pump (IMP) design

Incorporates a gear reducer and a programmable vector drive in a compact design for precise metering

Easy maintenance

Assembly of joints without any tools

Broad range of chemical compatibility

Due to the external GA seal arrangement and engineered composite seal housing, lantern, and rotating unit, the only metallic part in contact with the conveyed product is the rotor

Easily retrofits into existing units

Cavity design allows for conveyance of liquids, solids, and gases

Economical

By-product minimization with reduced chemical consumption and total cost of ownership for flow control systems is reduced

People Also Ask