SEEPEX BTEX – PARTICULARLY ROBUST HOPPER PUMP

MADE FOR EXTREMES

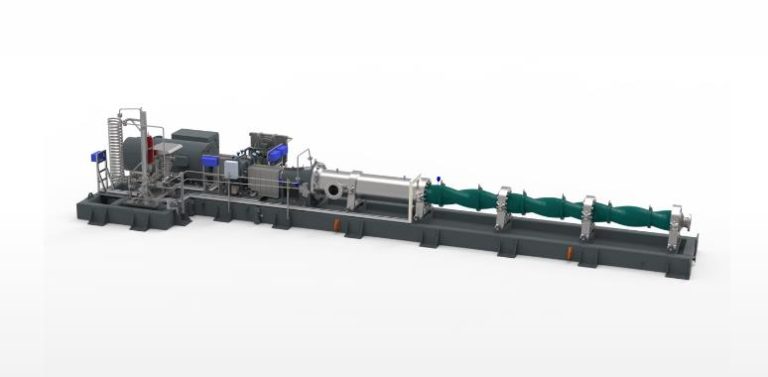

Powerful under extreme conditions: the BTEX hopper pumps SEEPEX are robustly built and designed with reinforced individual components for tough applications – e.g. for fermentation products in the agriculture and biogas industries. They are designed to allow contaminants to settle at the base of the hopper and be removed quickly and easily through large inspection openings for maximum availability and time savings during servicing work.

Introducing the SEEPEX BTEX Hopper Pump – Built for Robust Performance

The SEEPEX BTEX Hopper pump is a high-performance solution for handling particularly difficult pumping applications, such as those involving volatile organic compounds like benzene, toluene, ethylbenzene, and xylene (BTEX).

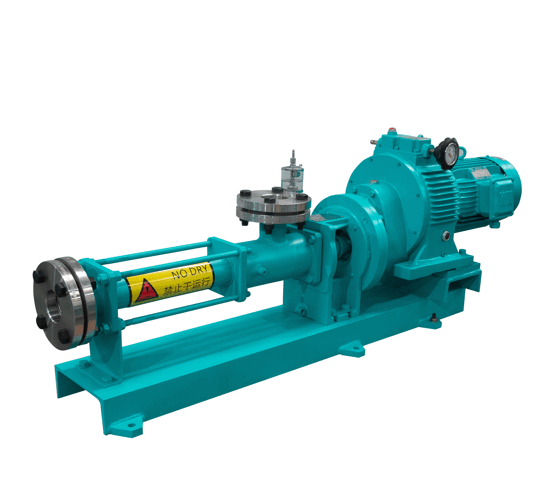

This pump is specifically designed to withstand tough environments and harsh operating conditions, thanks to its robust construction and durable materials. With its hopper design, the BTEX pump can handle highly viscous or solid-containing media, ensuring consistent flow rates with minimal shear forces.

Whether you need to pump chemicals, petrochemicals, or other challenging substances, the SEEPEX BTEX Hopper Pump is an excellent choice for reliable, efficient, and trouble-free operation.

Application of SEEPEX BTEX Hopper Pump in Robust Environments

SEEPEX BTEX Hopper Pump is an ideal solution for pumping applications in particularly robust environments. Its unique design allows for efficient pumping of media with high viscosity, solids content, and even chemicals containing BTEX (benzene, toluene, ethylbenzene, and xylene) compounds.

This pump’s hopper design enables it to handle highly viscous and abrasive media that would otherwise damage conventional pumps. Additionally, its robust construction ensures reliable operation even in harsh conditions.

The SEEPEX BTEX Hopper Pump has found numerous applications in various industries such as chemical production, oil and gas, wastewater treatment, and food processing. It is particularly suitable for transferring sludges, slurries, and other challenging media.

Overall, the SEEPEX BTEX Hopper Pump is a versatile and reliable pump that makes it an excellent choice for handling tough pumping applications in robust environments.

Optimum separation of solids

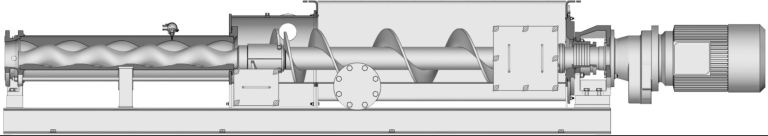

The rectangular cross section of the hopper design allows contaminants to be separated at the bottom of the hopper

Simply under control

Easy removal of contaminants through large inspection openings in the hopper and compression zone

Maximum availability

Through regular, simple removal of contaminants

Easy maintenance

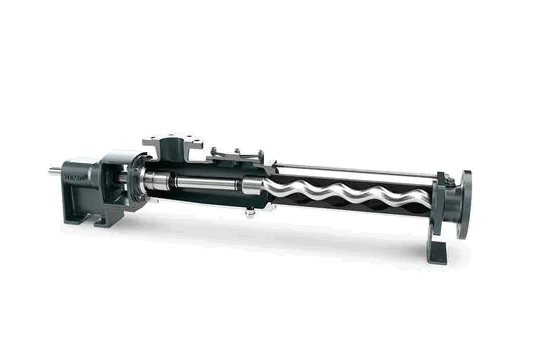

Quick and simple maintenance thanks to the sliding compression casing

Time-saving

The joints installed in the pump are exclusively universal joints – for very rapid replacement during servicing

Simply clean

Simple cleaning or infeed of liquids via integrated flange opening in the hopper

People Also Ask