Failure of High-Pressure Hydrogenation Gate Valve and Countermeasures

High-pressure hydrogenation gate valves are used to control the flow and pressure of hydrogen in hydrocracking and hydrofining processes. During production, high-pressure hydrogen reacts chemically with feedstock oil to improve the quality and yield of oil products. The stable performance of high-pressure hydrogenation gate valves ensures the stable transportation of high-pressure hydrogen, which in turn guarantees the stable output of the entire oil refining system and plays a crucial role in the safety and efficiency of the refining process.

However, high-pressure hydrogenation gate valves operate in harsh environments of high temperature (280–450°C), high pressure (16–27 MPa), and hydrogen, placing extremely high demands on all aspects of valve performance. To ensure their reliability and durability in such harsh conditions, the design and manufacture of high-pressure hydrogenation gate valves must strictly follow relevant standards, or even exceed them.

During operation, high-pressure hydrogenation gate valves are subjected to high-temperature and high-pressure conditions, facing severe hydrogen corrosion issues. Additionally, under the scouring of high-velocity hydrogen and combined with mechanical wear during valve opening and closing, the sealing surfaces of high-pressure hydrogenation valves are prone to failure, leading to internal or external leaks. Since the introduction of high-pressure hydrogenation gate valves in the oil refining industry, scouring wear and hydrogen corrosion have both affected valve service life. This article conducts an in-depth analysis of hydrogen corrosion and scouring wear in high-pressure hydrogenation gate valves and proposes proactive countermeasures.

Ⅰ.Analysis of hydrogen corrosion in high-pressure hydrogenation gate valves.

Hydrogen corrosion is a serious issue for valves in hydrogen-containing environments, especially under high-temperature and high-pressure conditions.

Causes and impacts of hydrogen Corrosion.

Current industry research on hydrogen corrosion mainly includes the following aspects:

- Hydrogen Embrittlement: Under high pressure, hydrogen atoms penetrate the metal lattice when in contact with metal materials, reducing the plasticity and toughness of the metal and accelerating corrosion.

- Electrochemical Corrosion: Hydrogen forms an electrochemical corrosion cell with the metal surface, causing corrosion reactions.

- Chemical Corrosion: Hydrogen reacts chemically with the metal surface to form hydrides, causing corrosion.

- Stress Corrosion: High-pressure hydrogen exerts stress on the metal, accelerating corrosion.

- Environmental Factors: Environmental factors such as temperature, humidity, and medium composition affect the corrosion degree of high-pressure hydrogenation gate valves by hydrogen.

After hydrogen corrosion occurs, the following main issues arise:

- Reduction in yield strength and tensile strength, with a significant decline in the physical properties of the metal material.

- Significant decrease in elongation and area reduction, indicating severe degradation of material plasticity and toughness.

- Fracture apperance changes from ductile to brittle, with materials becoming more brittle and fractures showing intergranular or transgranular failure.

- Shortened fatigue life, as hydrogen atoms accelerate the propagation of fatigue cracks in materials, greatly reducing fatigue life.

In summary, hydrogen corrosion is one of the key factors causing failure in high-pressure hydrogenation gate valves during operation.

Measures to mitigate hydrogen corrosion in high-pressure hydrogenation gate valves.

The selection of metal materials and surface treatment are critical because metal materials in high-pressure hydrogenation gate valves are prone to hydrogen corrosion.

Metal material selection.

When selecting materials, prioritize those with excellent hydrogen resistance, such as austenitic stainless steel, nickel-based alloy steel, and titanium alloy. During casting or forging, strictly control the content of phosphorus (P) and sulfur (S).

Surface treatment.

Surface treatment technologies can significantly improve the hydrogen resistance of materials. Common surface treatment processes include nitriding, carburizing, nickel plating, and plasma spraying. These treatments form a protective layer on the metal surface, effectively preventing hydrogen atoms from directly contacting the base material, thereby enhancing hydrogen embrittlement resistance and extending the service life of metal materials in hydrogen environments. Additionally, advanced surface treatment technologies such as diamond-like carbon (DLC) and ceramic coatings can also improve the hydrogen corrosion resistance of metal materials and reduce corrosion risks.

Ⅱ.Analysis of scouring wear in high-pressure hydrogenation gate valves.

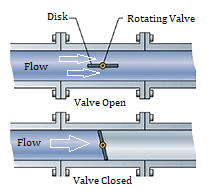

During long-term use, high-temperature and high-pressure hydrogen and feedstock oil flow at high velocity inside high-pressure hydrogenation gate valves, strongly scouring the surfaces of the valve disc and seat under such high-velocity and high-pressure conditions, causing the loss of metal material from the surface. This scouring wear is caused by the relative movement of hydrogen with components such as the disc and seat, particularly the influence of eddy currents in the internal grooves of the gate valve on particle movement and erosion. Prolonged scouring leads to wear, corrosion, and fatigue cracks on component surfaces, reducing the sealing performance and service life of high-pressure hydrogenation gate valves.

Scouring wear shown in high-pressure hydrogenation gate valves.

- Obvious Wear Marks on Disc and Seat Surfaces: Due to the high-velocity flow of hydrogen, the contact surfaces of the disc and seat are severely scoured, resulting in wear marks that gradually deepen and affect valve sealing performance.

- Pits and Cracks on Internal Wall Surfaces: Prolonged scouring and corrosion may cause pits and cracks on the surfaces of the disc and seat, reducing sealing performance and increasing leakage risks.

- Valve Leakage: Scouring wear can prevent the valve from closing completely, leading to leakage, which not only affects the stability and efficiency of the refining process but also causes environmental pollution.

- Triggering Production or Safety Accidents: Severe scouring wear can render high-pressure hydrogenation gate valves inoperable, leading to accidents.

Impacts of scouring wear on the service performance of the valve.

- Reduced Sealing Performance: Scouring wear causes hydrogen leakage, affecting the stability and efficiency of the refining process.

- Shortened Service Life: Increased maintenance and replacement frequency due to wear raises operational costs for refineries.

- Safety Risks: Severe scouring wear may trigger leakage and safety accidents, posing a serious threat to refinery safety.

Solutions to reduce scouring wear in high-pressure hydrogenation gate valves.

To address the issue of scouring wear, the following measures can be taken for high-pressur:

- Material Selection: Choose corrosion-resistant and wear-resistant materials such as nickel-based alloys during design to improve the wear and scouring resistance of the disc and seat.

- Structural Design Improvements: Modify the structural design of the disc and seat (e.g., adopt special shapes) to reduce hydrogen scouring force and extend service life.

- Surface Coating: Spray wear-resistant coatings on metal components in contact with the medium (e.g., disc and seat) to effectively enhance wear and corrosion resistance.

During operation, scouring wear of hydrogen medium on valves is a complex process. Selecting high-hardness metal materials, adopting advanced surface treatment processes, and controlling surface finish can significantly improve valve wear resistance and extend service life. Additionally, optimizing the flow channel design of high-pressure hydrogenation gate valves to reduce turbulence and dead zones can greatly reduce scouring wear by hydrogen medium.

With the development of new materials and processing technologies, the design and manufacturing capabilities of high-pressure hydrogenation gate valves are continuously improving, and their resistance to scouring wear and service life will be significantly enhanced.